Turkish Airlines' 225-Plane Boeing Order: Strategic Implications for Aviation and Engine Suppliers

The recent announcement of Turkish Airlines' potential order for 225 BoeingBA-- aircraft—comprising 150 737 MAX narrow-body jets and 75 787 Dreamliner widebodies—has sent ripples through the aerospace industry. This deal, still contingent on engine pricing and production slot availability[1], underscores the airline's aggressive expansion strategy and Boeing's renewed relevance in a market dominated by supply chain bottlenecks. Yet, the implications extend far beyond the manufacturer and operator. For investors, the order highlights critical vulnerabilities and opportunities in the global aerospace supply chain, particularly for engine manufacturers, component suppliers, and maintenance, repair, and overhaul (MRO) services.

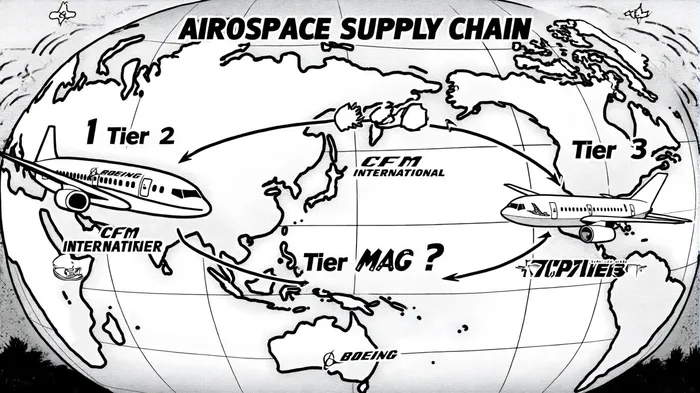

Supply Chain Vulnerabilities and Engine Supplier Dynamics

The 737 MAX and 787 programs are emblematic of Boeing's reliance on a fragmented global supply chain. For the 737 MAX, CFM International's LEAP engines are the sole powerplant, making pricing negotiations with Turkish Airlines a pivotal factor in finalizing the order[5]. Meanwhile, the 787's engines—supplied by General Electric and Rolls-Royce—have historically been a source of contention due to high maintenance costs[3]. According to a report by Forbes, Boeing's outsourcing strategy for the 787, which involves over 45 Tier 1 suppliers, has led to recurring quality control issues, including defective fuselage sections from Spirit AeroSystems and inconsistent wing manufacturing by Mitsubishi Heavy Industries[2]. These challenges have not only delayed deliveries but also eroded trust in the reliability of outsourced components.

For Turkish Airlines, the stakes are high. The airline's CEO, Bilal Eksi, has openly stated that Airbus remains a viable alternative if Boeing fails to meet contractual terms[4]. This flexibility reflects a broader industry trend: airlines are increasingly diversifying their supplier base to mitigate risks. However, such diversification is not without cost. Turkish Airlines has already secured 230 Airbus aircraft, including 150 A321neos and 70 A350s[6], further complicating its fleet modernization plans.

Investment Opportunities in Tier 2/Tier 3 Suppliers and MRO Services

The ripple effects of Turkish Airlines' Boeing order are most pronounced among Tier 2 and Tier 3 suppliers, which produce subsystems and mission-critical components. For instance, companies specializing in airframe structures, flight controls, and hydraulic systems—such as those supplying parts for the 787's composite fuselage—stand to benefit from increased demand. A study by Brennan Inc. notes that Tier 2 suppliers, which assemble parts for Tier 1 companies, are particularly vulnerable to quality control lapses but also offer high-margin opportunities for firms with advanced manufacturing capabilities[7].

Moreover, Turkish Airlines' push to localize aircraft component production in Turkey could catalyze growth for domestic suppliers. The airline has already begun manufacturing seats for Boeing and Airbus aircraft and is exploring partnerships to produce engine parts[8]. This move aligns with Turkey's broader ambition to become a regional aerospace hub, a strategy that could attract foreign direct investment into its supply chain ecosystem.

The MRO sector, too, is poised for expansion. Turkish Technic, the airline's MRO arm, has recently expanded its capacity at Istanbul Airport, with plans to double its maintenance capabilities[9]. This infrastructure investment is critical, as next-generation aircraft like the 787 require specialized maintenance protocols. Turkish Technic's partnerships with Emirates and Silk Way West Airlines further underscore its growing role in the global MRO market[10].

Risks and Strategic Considerations

While the order presents opportunities, investors must remain cautious. Delays in Boeing's production slots—exacerbated by ongoing quality control issues—could push delivery timelines beyond 2030[11]. Additionally, the airline's dual reliance on Boeing and Airbus increases operational complexity, particularly in training and spare parts logistics. For engine manufacturers like CFM and GE, the negotiations with Turkish Airlines highlight the need to balance pricing flexibility with long-term service agreements to secure recurring revenue streams.

Geopolitical risks also loom large. Turkey's strategic position at the crossroads of Europe and Asia makes it a key player in regional aviation, but its economic volatility and regulatory environment could deter foreign suppliers. Conversely, the airline's domestic production initiatives may insulate it from some of these risks while fostering a more resilient supply chain.

Conclusion

Turkish Airlines' 225-plane Boeing order is more than a procurement deal—it is a microcosm of the aerospace industry's evolving dynamics. For investors, the focus should shift from the manufacturer to the broader ecosystem of suppliers, MRO providers, and domestic producers. Companies with expertise in quality control, digital supply chain integration, and localized manufacturing—particularly those with ITAR and AS 9100 certifications—stand to gain the most. As Boeing and Turkish Airlines navigate the final hurdles of this deal, the true winners may be those operating in the shadows of the supply chain.

Comentarios

Aún no hay comentarios