Tesla's Diminishing Dominance in China and the Copper Bottleneck Threating EV Growth

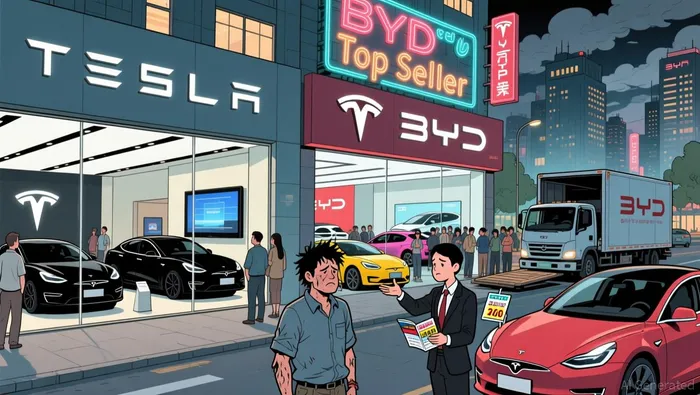

The electric vehicle (EV) revolution, once synonymous with Tesla's meteoric rise, is now facing a pivotal inflection point. In China-the world's largest EV market-Tesla's dominance is eroding, while local rivals like BYD are surging ahead. Simultaneously, a looming copper bottleneck threatens to amplify production costs and disrupt supply chains, compounding risks for investors. This analysis examines the interplay of these trends and their implications for strategic reallocation in the EV sector.

Tesla's Decline in China: A Structural Shift

Tesla's market share in China has plummeted from 7.8% in 2023 to 5.5% in November 2025, according to data from Reuters. This decline reflects not only intensifying competition but also Tesla's strategic missteps. In Q4 2025, TeslaTSLA-- delivered 418,227 vehicles in China-a 16% drop year-over-year-while BYD's full-year sales reached 2.26 million units, overtaking Tesla as the global EV leader. BYD's success stems from its vertically integrated supply chain, competitive pricing, and localized production, which have allowed it to outmaneuver Tesla in a market where cost efficiency and regulatory adaptability are paramount.

Tesla's struggles are compounded by external factors. The expiration of the U.S. federal EV tax credit and trade tensions have weakened demand in North America, forcing the company to pivot toward autonomous driving and robotics-a shift that diverts resources from its core EV business. Meanwhile, in China, Tesla's reliance on imported components and its inability to match BYD's price competitiveness have eroded its market position.

Tesla's struggles are compounded by external factors. The expiration of the U.S. federal EV tax credit and trade tensions have weakened demand in North America, forcing the company to pivot toward autonomous driving and robotics-a shift that diverts resources from its core EV business. Meanwhile, in China, Tesla's reliance on imported components and its inability to match BYD's price competitiveness have eroded its market position.

The Copper Bottleneck: A Systemic Risk for EV Growth

The EV industry's reliance on copper-a critical input for batteries, motors, and charging infrastructure-has created a new vulnerability. Each EV requires 3–4 times more copper than a conventional vehicle, and global demand is projected to reach 28 million metric tons by 2025, driven largely by China's dominance in processing and consumption. However, supply constraints are tightening. Declining ore grades, high mining costs, and geopolitical disruptions (e.g., export controls in the Democratic Republic of Congo and Indonesia) are straining the copper supply chain.

Copper prices have surged to record highs above $11,600 per ton in late 2025, driven by depleted inventories and U.S. stockpiling efforts. For EV manufacturers, this volatility raises production costs and threatens margins. While Tesla has not yet reported specific cost increases tied to copper in China, the broader trend of rising material prices could amplify its challenges, particularly as it shifts away from China-made components to avoid tariffs.

BYD's Resilience: Vertical Integration and Strategic Flexibility

BYD's ability to navigate these headwinds highlights the advantages of vertical integration. By controlling battery production, refining capacity, and even lithium mining operations in Brazil, BYD has insulated itself from raw material price swings. Its localized manufacturing in Europe and AI-driven optimization further reduce dependency on global supply chains. In contrast, Tesla's reliance on external suppliers and its lack of upstream control leave it more exposed to copper bottlenecks and geopolitical risks.

Moreover, BYD's 16.9% share of the global EV battery market- driven by its expertise in lithium-iron phosphate batteries-has enabled it to maintain cost efficiency and scale production rapidly. This strategic depth allows BYD to absorb input cost pressures more effectively than Tesla, which has struggled to replicate such integration.

Investor Implications: Reallocating for Resilience

For investors, the erosion of Tesla's dominance and the copper bottleneck signal a need to reassess sector allocations. Key risks include:

1. Supply Chain Vulnerability: Companies without vertical integration or diversified sourcing face heightened exposure to copper price volatility and geopolitical disruptions.

2. Margin Compression: Rising material costs could squeeze margins for manufacturers lacking cost-control mechanisms, particularly in price-sensitive markets like China.

3. Regulatory and Trade Risks: U.S.-China trade tensions and tariffs are reshaping production strategies, favoring firms with localized or diversified supply chains.

Strategic reallocation should prioritize firms with:

- Vertical Integration: BYD's control over batteries and raw materials offers a blueprint for mitigating bottlenecks.

- Geographic Diversification: Companies with localized production (e.g., BYD's European plants) can reduce logistics costs and geopolitical risks.

- Innovation in Recycling and Efficiency: Advances in copper recycling and battery technology may alleviate long-term supply constraints.

Conclusion

Tesla's waning influence in China underscores the importance of adaptability in the EV sector. While the company remains a technological innovator, its strategic and supply chain weaknesses have created openings for rivals like BYD. Meanwhile, the copper bottleneck-a systemic risk for the entire industry-demands a reevaluation of investment theses. Investors who prioritize firms with vertical integration, geographic diversification, and technological agility will be better positioned to navigate the uncertainties ahead.

Comentarios

Aún no hay comentarios