The Strategic Case for Investing in Additive Manufacturing Supply Chain Innovators: Linde Advanced Material Technologies and Velo3D

The global shift toward industrial self-sufficiency and the urgent need to secure critical supply chains have positioned additive manufacturing (AM) as a cornerstone of national economic and defense strategy. In the United States, this transformation is being driven by partnerships between cutting-edge technology firms and the Department of Defense, with LindeLIN-- Advanced Material Technologies and Velo3DVELO-- emerging as pivotal players. Their collaboration to develop a fully domestic AM supply chain for the U.S. Navy not only addresses immediate operational needs but also aligns with broader policy goals of reducing reliance on foreign materials and processes. For investors, this represents a compelling opportunity to capitalize on a sector poised for exponential growth, underpinned by technological innovation and strategic policy tailwinds.

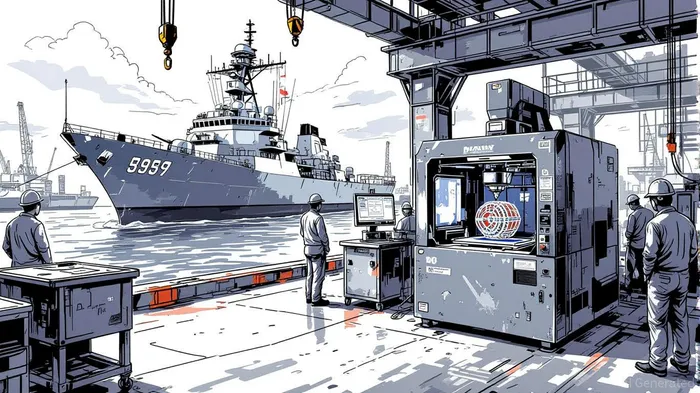

A Domestic Supply Chain for Naval Resilience

The U.S. Navy’s 2025 shipbuilding initiative has identified additive manufacturing as a critical enabler of fleet readiness and operational flexibility. Central to this effort is the partnership between Linde Advanced Material Technologies and Velo3D, which has been awarded a contract to produce corrosion-resistant CuNi (70-30 Copper-Nickel) powder for naval systems. Linde’s TRUFORM™ metal powders, manufactured at its Indianapolis facility, are specifically tailored for AM applications, ensuring high-quality, consistent feedstock for Velo3D’s Sapphire XC large-format printers [1]. This collaboration eliminates bottlenecks in the supply chain by producing materials and components entirely within the United States, a critical step in aligning with the Maritime Industrial Base (MIB) Program’s mandate to strengthen national manufacturing resiliency [1].

The strategic importance of this partnership lies in its alignment with ITAR (International Traffic in Arms Regulations) compliance and the use of domestically sourced materials. By eliminating reliance on foreign powder suppliers, the project mitigates risks associated with geopolitical instability and supply chain disruptions. For instance, Linde’s investment in optimizing its powder atomization process—detailed in a recent TCT Magazine report—has enhanced the performance of CuNi alloys, making them ideal for naval applications where corrosion resistance and mechanical strength are paramount [3]. This technical expertise, combined with Velo3D’s proprietary printing technology, creates a closed-loop system that prioritizes both quality and security.

Policy Tailwinds and National Security Imperatives

The U.S. government’s push for industrial self-sufficiency has accelerated in recent years, driven by the need to counter China’s dominance in critical material production and to insulate domestic industries from global shocks. The MIB Program, which supports the development of advanced manufacturing capabilities for maritime defense, explicitly emphasizes the role of AM in achieving these goals. Linde and Velo3D’s collaboration directly addresses this objective by providing a scalable, domestically produced solution for mission-critical components. According to a report by Inovar Communications, the Metal AM sector is projected to grow at a compound annual rate of 21% through 2030, with defense applications accounting for a significant share of this expansion [4].

Moreover, the partnership aligns with the Biden administration’s broader industrial policy, which includes incentives for reshoring advanced manufacturing and investing in R&D for strategic technologies. The U.S. Navy’s recent focus on AM’s performance in dynamic marine environments—highlighted at the RAPID + TCT 2025 conference—further underscores the sector’s strategic value [2]. By securing a contract to produce CuNi components at no cost to Navy stakeholders, Linde and Velo3D are not only demonstrating their technological prowess but also positioning themselves as key beneficiaries of a policy-driven market shift.

Market Dynamics and Long-Term Value Creation

The additive manufacturing market is transitioning from niche prototyping to large-scale industrial production, with defense and aerospace leading the charge. Linde’s expertise in material science and Velo3D’s leadership in metal AM hardware create a symbiotic relationship that is uniquely positioned to capture this growth. Linde’s recent expansion of its powder atomization lab, for example, is expected to accelerate the development of next-generation alloys tailored for AM, further solidifying its competitive edge [3]. Meanwhile, Velo3D’s Sapphire XC printer, with its ability to produce large, complex parts, addresses a critical gap in naval shipbuilding, where traditional manufacturing methods are often cost-prohibitive or logistically challenging.

From an investment perspective, the partnership’s alignment with U.S. defense priorities reduces exposure to market volatility and creates a durable revenue stream. The Metal AM Market 2025 report notes that companies like Linde and Velo3D are “shaping the evolving landscape of metal additive manufacturing” through innovations in materials and process optimization [4]. As the Navy scales its AM adoption, the demand for Linde’s TRUFORM™ powders and Velo3D’s printing solutions is likely to grow exponentially, supported by both public and private sector contracts.

Conclusion

The collaboration between Linde Advanced Material Technologies and Velo3D exemplifies the convergence of technological innovation, strategic policy, and market demand in the additive manufacturing sector. By delivering a fully domestic solution for U.S. Navy shipbuilding, they are not only addressing immediate operational needs but also laying the groundwork for a resilient, self-sufficient industrial base. For investors, this represents a rare opportunity to align with a sector that is both economically transformative and strategically indispensable. As the U.S. continues to prioritize domestic production and national security, the value of companies like Linde and Velo3D will only continue to rise.

Source:

[1] Linde Advanced Material Technologies and Velo3D Advance U.S. Navy Shipbuilding with Fully Domestic Additive Manufacturing Supply Chain [https://finance.yahoo.com/news/linde-advanced-material-technologies-velo3d-130000300.html]

[2] RAPID + TCT 2025: A guide to North America's definitive additive manufacturing event [https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/latest-additive-manufacturing-3d-printing-news/rapid-tct-2025-guide-north-america-definitive-additive-manufacturing-event/]

[3] Linde to open small-scale metal powder atomiser lab [https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/linde-open-small-scale-metal-powder-atomiser-lab/]

[4] VoxelMatters launches pre-sale for Metal AM Market 2025 report [https://www.voxelmatters.com/voxelmatters-launches-pre-sale-for-metal-am-market-2025-report/]

Comentarios

Aún no hay comentarios