Securing the Future: U.S. Critical Mineral Supply Chains and Lithium Investment Opportunities in the EV Transition

The transition to electric vehicles (EVs) is not merely a technological revolution but a geopolitical and economic reordering. At its core lies a dependency on critical minerals—lithium, graphite, rare earth elements—that underpin the batteries and components of the clean energy era. For the United States, securing these supply chains has become a matter of national urgency. According to a report by the U.S. Department of Energy (DOE), the Biden-Harris Administration has allocated over $3 billion in grants and loans to bolster domestic production, recycling, and processing of critical minerals, with a specific focus on reducing reliance on foreign entities of concern (FEOCs) [1]. This strategic pivot reflects a broader recognition that energy independence and industrial competitiveness are inextricably linked.

The Lithium Imperative: Corporate-Government Synergies

Lithium, the linchpin of the EV battery industry, has emerged as a focal point for U.S. policy and investment. The administration's efforts to insulate the domestic supply chain from global volatility are exemplified by its engagement with private-sector partners. Chevron's recent foray into the lithium sector—acquiring leasehold acreage in Texas and Arkansas using direct lithium extraction (DLE) technology—signals a shift in corporate strategy toward energy security [2]. This move aligns with federal incentives under the Inflation Reduction Act (IRA), which offers tax credits for domestically sourced materials, creating a fertile ground for innovation and capital deployment.

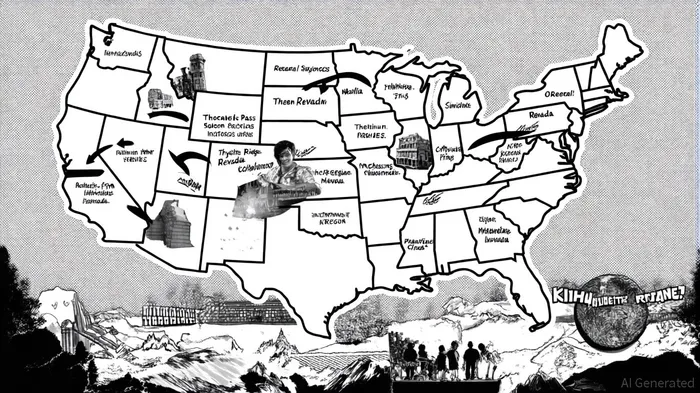

Equally significant is the potential for government equity stakes in critical mineral projects. Reports suggest that the U.S. government is considering acquiring a stake in Lithium Americas (LAC), owner of the Thacker Pass project in Nevada, the largest lithium resource in the country [3]. Such a partnership would not only de-risk capital-intensive ventures but also ensure that strategic assets remain under U.S. control. Thacker Pass, which received a $2.26 billion loan from the DOE, is projected to produce 160,000 tons of lithium carbonate annually across five phases, though recent scrutiny of its viability has placed the loan in jeopardy [1]. This underscores the delicate balance between ambition and pragmatism in scaling domestic production.

Diversifying the Supply Chain: From Extraction to Recycling

The U.S. strategy extends beyond raw material extraction to encompass midstream processing and end-of-life recycling—a circular economy approach critical to long-term resilience. For instance, Ioneer LtdIONR--.'s Rhyolite Ridge project in Nevada, backed by a $996 million DOE loan, is poised to produce 22,000 tons of lithium carbonate equivalent annually, with offtake agreements secured by Ford and Toyota–Panasonic [1]. Similarly, General Motors' 38% stake in Thacker Pass, coupled with a 20-year offtake agreement, illustrates how vertical integration can mitigate supply chain risks.

Yet, the most transformative opportunities lie in recycling and byproduct recovery. A study by the Atlantic Council highlights that recycling magnet-grade rare earths and recovering byproducts from existing mining operations could significantly reduce import dependency [3]. The DOE's emphasis on circular economy practices—such as Redwood Materials' battery recycling facility in South Carolina—reflects this vision, with $200 million in federal funding accelerating the development of closed-loop systems [3].

Challenges and the Path Forward

Despite these strides, challenges persist. Equity financing remains a hurdle for projects like Rhyolite Ridge, which requires additional capital to commence construction in late 2025 [1]. Regulatory delays and environmental concerns also complicate expansion, as seen in the permitting challenges faced by IoneerIONR-- and Lithium Americas. Moreover, the U.S. currently lacks lithium processing capacity, a gap that must be filled to avoid replicating China's dominance in downstream manufacturing [1].

To address these issues, the administration has imposed tariffs on Chinese EV and grid storage batteries, aiming to level the playing field for domestic producers [3]. These measures, combined with the Defense Production Act's incentives for critical mineral production, signal a coordinated effort to reshape global supply dynamics.

Investment Opportunities: A Strategic Outlook

For investors, the U.S. critical mineral sector presents a compelling mix of risk and reward. The battery industry's pledge of $100 billion in U.S. investments this decade—contingent on continued government support—highlights the scale of opportunity [3]. Key areas to monitor include:

1. Lithium Extraction and Processing: Projects like Thacker Pass and Rhyolite Ridge, supported by federal loans and equity partnerships.

2. Recycling and Circular Economy: Firms like Redwood Materials and RecycLiCo, which are scaling battery recycling infrastructure.

3. Midstream Innovation: Companies developing sustainable processing technologies, such as Syrah Vidalia's graphite processing or Century Lithium's hydrochloric acid leaching methods [1].

Conclusion

The U.S. critical mineral supply chain is at a pivotal juncture. Through strategic corporate-government partnerships, the nation is laying the groundwork for a self-sufficient, resilient, and ethically sourced supply chain. While challenges remain, the alignment of policy, capital, and innovation offers a roadmap to secure both energy independence and economic competitiveness. For investors, the lithium sector—anchored by projects like Thacker Pass and Rhyolite Ridge—represents not just a financial opportunity but a stake in the future of clean energy.

Comentarios

Aún no hay comentarios