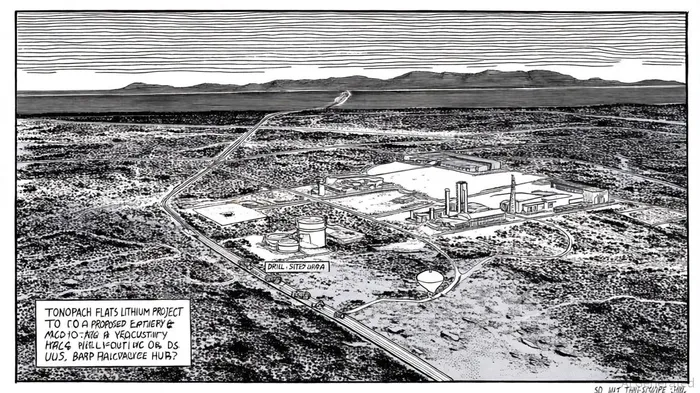

Disrupting the Lithium Supply Chain: American Battery Technology's Tonopah Project and Its Investment Potential

The global transition to clean energy hinges on a single element: lithium. As electric vehicles (EVs) and energy storage systems redefine industrial demand, the lithium market is poised for explosive growth. By 2030, demand is projected to reach 3.7 million tonnes of lithium carbonate equivalent (LCE), nearly double the 2025 level, according to metals-hub projections. In this context, American BatteryABAT-- Technology Company's (ABTC) Tonopah Flats Lithium Project (TFLP) emerges as a critical player, leveraging innovative technology, strategic government support, and a unique geological resource to disrupt the lithium supply chain. For investors, the question is not whether lithium demand will grow, but whether ABTC can scale its operations to capture a significant share of this market-and deliver outsized returns.

Strategic Positioning: A Domestic Supply Chain Anchor

ABTC's TFLP, located in Nevada's lithium-rich claystone deposits, is uniquely positioned to address U.S. supply chain vulnerabilities. The project has been designated a "Covered Priority Project" under President Trump's executive order to boost domestic mineral production, fast-tracking permits through the FAST-41 Permitting Council, as detailed on ABTC's Tonopah Flats project page. This regulatory acceleration is critical, as traditional lithium projects often face multi-year delays due to environmental reviews. ABTC has already completed all required National Environmental Policy Act (NEPA) baseline studies, a milestone that reduces permitting risks and signals operational readiness, according to a Business Insider release.

Government backing extends beyond policy. The project has secured a $900 million Letter of Interest from the U.S. Export-Import Bank and a $57.7 million grant from the Department of Energy, as described in an ABTC press release. These funds are earmarked for constructing a 30,000-tonne-per-year lithium hydroxide refinery, a facility that could become a cornerstone of U.S. battery material production. With the Inflation Reduction Act incentivizing domestic mineral processing, ABTC's alignment with national security and energy transition goals positions it to attract further public and private capital.

Technological Innovation: Selective Leach vs. Traditional Methods

ABTC's competitive edge lies in its proprietary selective leach extraction (SLE) technology, which targets lithium in claystone with minimal environmental impact. Unlike traditional hard rock mining or brine evaporation, which require extensive land use, water consumption, and chemical byproducts, SLE employs a closed-loop process that reduces energy inputs and waste, as ABTC explains on its Tonopah Flats project page. This approach contrasts sharply with Tesla's high-energy milling method for claystone, which remains energy-intensive, as outlined in a Critical Metals article.

Comparative analyses highlight SLE's advantages. Brine evaporation, the dominant method in South America's Lithium Triangle, takes 18–24 months to concentrate lithium and consumes vast quantities of water-a critical limitation in arid regions, as noted in an iBatteryMetals analysis. Hard rock mining, while faster, generates acid mine drainage and high carbon emissions, according to a ScienceDirect study. ABTC's SLE, by contrast, avoids these pitfalls, offering a cleaner, more scalable alternative. While Direct Lithium Extraction (DLE) technologies are also emerging, ABTC's claystone-focused approach expands the global lithium resource base, which is currently dominated by brine and hard rock deposits, as covered in a Farmonaut overview.

Cost Competitiveness: A $4,302-per-Tonne Edge

Production costs are a key determinant of ABTC's long-term viability. The company's April 2024 Amended Initial Assessment estimates a production cost of $4,302 per tonne for battery-grade lithium hydroxide, per the Amended Initial Assessment. This figure is significantly lower than hard rock producers (typically $8,000–$12,000 per tonne) and competitive with brine operations ($4,000–$6,000 per tonne), according to a DiscoveryAlert analysis. While brine producers benefit from low-cost solar evaporation, ABTC's SLE technology mitigates the need for large-scale water use, reducing operational risks in water-scarce regions.

Government grants further enhance cost efficiency. The $57.7 million DoE grant, for instance, covers 30% of the refinery's capital costs, effectively lowering ABTC's breakeven price. By comparison, DLE projects-though promising-remain capital-intensive and unproven at commercial scale, as argued in a Wood Mackenzie opinion. ABTC's ability to leverage public funding while maintaining a cost structure aligned with industry benchmarks strengthens its value proposition.

Market Dynamics: Demand, Supply Gaps, and Investment Risks

The urgency of ABTC's mission is underscored by looming supply gaps. Benchmark analysis forecasts a 572,000-tonne lithium shortfall by 2034, driven by the 5–25-year lag in mine development relative to downstream demand, per a CarbonCredits analysis. ABTC's 30,000-tonne annual output, while modest compared to giants like Albemarle or Ganfeng, could fill a critical niche in the U.S. market, where automakers like General Motors and Tesla are aggressively securing domestic supply chains, as noted in a GlobeNewswire release.

However, risks persist. Scaling SLE to commercial production requires overcoming technical challenges, such as optimizing leach efficiency and managing byproduct streams. Additionally, ABTC faces competition from DLE innovators and established brine producers, who may undercut prices as technology matures. The company's reliance on government grants also introduces political risk, though bipartisan support for energy security suggests continued policy tailwinds.

Conclusion: A High-Conviction Bet on the Energy Transition

For early investors, ABTC represents a high-conviction opportunity at the intersection of technological innovation and geopolitical strategy. Its Tonopah project combines a unique resource base, cost-competitive production, and regulatory tailwinds to address a supply chain bottleneck with global implications. While execution risks are non-trivial, the potential rewards-capitalizing on a $514 billion investment need in lithium production by 2030, as projected by metals-hub, justify a strategic allocation for those willing to bet on the energy transition.

Comentarios

Aún no hay comentarios