Digital Transformation in Sustainable Manufacturing: Strategic Cloud Adoption and Its Impact on ESG and Operational Efficiency

The convergence of digital transformation and sustainability is reshaping the industrial landscape, with cloud computing emerging as a linchpin for achieving both operational efficiency and robust ESG (Environmental, Social, and Governance) performance. Grundfos' partnership with Dassault Systèmes exemplifies this trend, offering a blueprint for how manufacturers can leverage cloud-based technologies to align profitability with planetary boundaries. By deploying Dassault's 3DEXPERIENCE platform, Grundfos has not only accelerated innovation but also embedded sustainability into its product lifecycle management, reducing carbon emissions and enhancing water stewardship. This case study, alongside broader industry data, underscores the strategic imperative for industrials to adopt cloud solutions as a dual engine for ESG compliance and operational agility.

Grundfos and Dassault Systèmes: A Model for Sustainable Digitalization

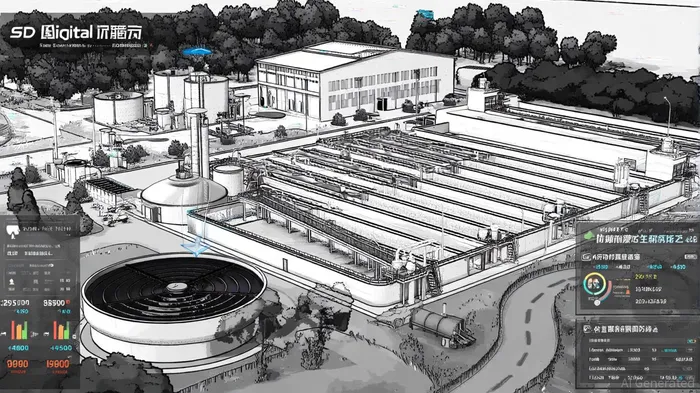

Grundfos' collaboration with Dassault Systèmes centers on the 3DEXPERIENCE platform, which integrates AI-powered virtual twins of the water lifecycle. These virtual models enable predictive maintenance, real-time analytics, and traceability across supply chains, directly supporting Grundfos' ESG goals. By 2024, the company had already reduced carbon emissions by 10.5% compared to 2023 and saved 1.5 billion cubic meters of water for end users[6]. Such outcomes are not accidental but stem from a deliberate strategy to digitize operations while prioritizing circular business practices and climate action[2].

Dassault Systèmes' own ESG credentials further validate this partnership. The company's recognition with a Platinum EcoVadis medal and an MSCIMSCI-- ESG rating of 'AAA'[5] signals its commitment to sustainability, aligning with Grundfos' mission to decarbonize its operations. This synergy between technological capability and environmental ambition illustrates how cloud platforms can serve as a bridge between innovation and sustainability, enabling manufacturers to meet global standards like the UN Sustainable Development Goals (SDGs) and the Corporate Sustainability Reporting Directive (CSRD).

Cloud Adoption: A Catalyst for Industry-Wide ESG and Efficiency Gains

Grundfos' experience is part of a broader industry shift. According to a 2025 Deloitte survey, 57% of manufacturers now utilize cloud computing to support smart manufacturing initiatives, which have led to measurable improvements in production output, employee productivity, and operational capacity[1]. These gains are amplified by AI and automation, which enable real-time adjustments, predictive maintenance, and optimized resource management[2]. For instance, cloud-based systems reduce waste and energy consumption while improving supply chain transparency—a critical factor in mitigating carbon footprints[3].

The financial and environmental ROI of cloud adoption is equally compelling. Migrating to cloud infrastructure can reduce carbon emissions by up to 84% compared to traditional on-premises systems[1], while companies report cost savings of 20–30% through optimized resource allocation and streamlined supply chains[2]. For industrials, this translates to a dual benefit: enhanced profitability and alignment with ESG benchmarks. Microsoft's Cloud for Sustainability, for example, provides tools to track emissions and ESG performance against goals, using data visualizations to identify areas for improvement[3].

Strategic Implications for Industrial Investors

For investors, the integration of cloud technologies into manufacturing offers a clear pathway to long-term value creation. KPMG's 2025 global tech report highlights that 76% of industrial manufacturers are digitally mature, with 34% already achieving ROI from AI use cases[1]. This digital maturity is closely tied to ESG performance, as evidenced by the Manufacturing ESG Maturity Benchmark Study 2024–2025, which evaluates 22 global enterprises on over 80 metrics across environmental, social, and governance dimensions[2]. Top performers like General MotorsGM-- and WhirlpoolWHR-- are recognized for their transparent ESG reporting and clean technology adoption[2], reinforcing the link between digital transformation and sustainability leadership.

However, challenges remain. Workforce upskilling, cybersecurity risks, and interoperability issues in supply chains require strategic investments. Yet, as cloud platforms evolve to include hybrid and private deployment models tailored to industrial needs, these barriers are increasingly surmountable[4]. The growing emphasis on data readiness and real-time analytics further positions cloud adoption as a cornerstone of competitive advantage in a decarbonizing economy.

Conclusion: The Future of Industrial Investment

The Grundfos-Dassault Systèmes partnership and broader industry trends demonstrate that cloud adoption is no longer optional for manufacturers aiming to thrive in a sustainability-driven world. By reducing operational costs, enhancing traceability, and aligning with ESG frameworks, cloud technologies offer a scalable solution to the dual challenges of climate action and profitability. For industrial investors, the message is clear: prioritizing cloud-enabled digital transformation is not just a strategic imperative but a financial one. As the sector moves toward a net-zero future, those who embrace these innovations will lead the next industrial revolution.

Comentarios

Aún no hay comentarios