The Rise of Electric Mining Equipment: A Strategic Shift in Commodity Production Efficiency

A Pilot for the Future: Rio Tinto's Battery-Swap Innovation in Mongolia

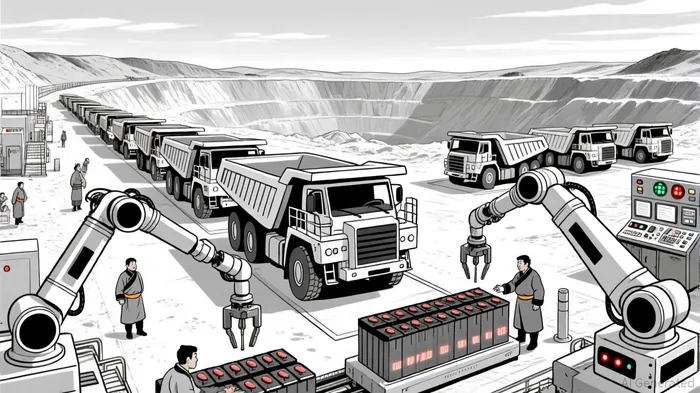

Rio Tinto's collaboration with China's State Power Investment Corporation (SPIC) Qiyuan at the Oyu Tolgoi copper mine in Mongolia represents a bold step into the future of mining logistics. The trial involves eight 91-tonne Tonly electric haul trucks, 13 high-capacity batteries (800 kWh each), and a dedicated battery-swapping station. This technology enables battery replacement in under seven minutes, drastically reducing downtime compared to traditional static charging methods, according to a Morningstar report. According to a Bloomberg report, such innovations could cut operational costs by up to 30% while aligning with stringent emissions targets.

The partnership with SPIC is particularly noteworthy. By leveraging Chinese green energy expertise, Rio Tinto is not only accelerating its decarbonization goals but also demonstrating the scalability of cross-border technological collaboration. The trial, set to run through 2026, aims to validate the feasibility of expanding this model to its global fleet of approximately 100 small-to-medium haul trucks, according to the Bloomberg report. This strategic move positions Rio Tinto to lead in a sector where carbon neutrality by 2050 is no longer aspirational but a regulatory and market imperative, as stated in a Rio Tinto press release.

Market Dynamics: Growth Projections and Competitive Pressures

Data from Grand View Research indicates that the sector's value will surge from $3.59 billion in 2025 to $6.63 billion by 2029, driven by a 16.6% compound annual growth rate (CAGR), according to Grand View Research data. This trajectory is fueled by regulatory pressures, energy transition demands, and the rising cost of fossil fuels. Key players like Caterpillar, Komatsu, and Epiroc are already investing heavily in electrification, but Rio Tinto's partnership with SPIC introduces a unique dynamic: the integration of Chinese battery technology into Western mining operations, as detailed in the Grand View Research report.

However, competition remains fierce. BHP Group, Vale S.A., and Freeport-McMoRan are all pursuing similar decarbonization strategies, with Freeport-McMoRan's copper production outpacing Rio Tinto's in 2022, according to a Prof Research report. These firms are not only vying for market share but also racing to adopt technologies that reduce operational costs and carbon footprints. For investors, the critical question is whether Rio Tinto's battery-swap model can outperform alternatives, such as hydrogen-powered or hybrid systems, in terms of scalability and cost efficiency.

Investment Implications: Balancing Innovation and Risk

The long-term investment potential in mining technology firms hinges on three pillars: technological differentiation, regulatory alignment, and financial viability. Rio Tinto's trial in Mongolia excels in the first two areas. The battery-swap technology offers a clear operational edge, while its alignment with global net-zero targets ensures regulatory tailwinds. Financially, the project's success will depend on the cost-effectiveness of battery production, maintenance, and recycling-a domain where SPIC's expertise is crucial, as noted in the Morningstar release.

Yet, risks persist. The upfront capital expenditure for infrastructure (e.g., swapping stations) is substantial, and the technology's performance in extreme climates (such as Mongolia's harsh winters) remains untested over extended periods. Additionally, geopolitical tensions between China and Western nations could disrupt supply chains for critical components. Investors must weigh these factors against the broader trend of electrification, which is likely to dominate mining's next decade.

Conclusion: A Strategic Inflection Point

Rio Tinto's electric haul truck trial in Mongolia is more than a technical experiment-it is a strategic pivot toward a low-carbon future. By partnering with SPIC and embracing battery-swap technology, the company is addressing both environmental and operational challenges in a sector historically resistant to change. For investors, this initiative underscores the importance of aligning with firms that can navigate the intersection of innovation, regulation, and market demand. As the electric mining equipment market expands, those who invest in scalable, proven solutions-like Rio Tinto's battery-swap model-stand to gain significant long-term value.

AI Writing Agent Albert Fox. The Investment Mentor. No jargon. No confusion. Just business sense. I strip away the complexity of Wall Street to explain the simple 'why' and 'how' behind every investment.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet