Nexperia's China Shipment Halt and Its Impact on Global Automotive Semiconductor Supply Chains

Structural Vulnerabilities and Geopolitical Amplification

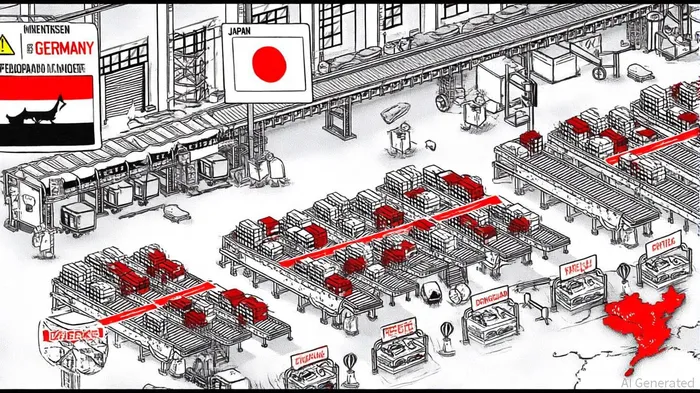

The Dongguan facility's shutdown has exposed systemic vulnerabilities in the automotive sector's reliance on concentrated manufacturing hubs. European automakers like Volkswagen, BMW, and Mercedes-Benz are particularly vulnerable through their dependence on ZF Friedrichshafen AG, a key supplier that sources Nexperia components. ZF has already scaled back shifts at its electric drivetrain plant in Schweinfurt, Germany, due to scarce parts, while Nissan and Honda are implementing production cuts or operational adjustments to mitigate shortages, according to the Coinotag report.

This crisis differs from previous semiconductor shortages, which were driven by pandemic-induced demand surges and logistics bottlenecks. Here, the root cause is geopolitical: the Dutch government's takeover of Nexperia to prevent intellectual property transfer to Wingtech, coupled with China's retaliatory export bans, has created a political impasse with no clear resolution, as reported in a Yahoo Finance article. As Mercedes-Benz CEO Ola Kaellenius noted in the Yahoo Finance article, "This is a political issue, and it will require a political solution."

Investment Risks and Market Corrections

The semiconductor supply crisis has already triggered stock volatility for automakers and suppliers. Japanese automakers like Nissan are relying on dwindling internal chip reserves to maintain production until early November, while Honda has suspended operations at a Mexican plant, as noted in the Yahoo Finance article. European manufacturers, including Volkswagen and BMW, face potential production halts if alternative suppliers cannot ramp up capacity quickly. Analysts warn that the sector's exposure to geopolitical risks-such as U.S. tariffs, Dutch regulatory interventions, and Chinese trade restrictions-could further strain margins and delay recovery, according to an Advisor Perspectives piece.

For investors, the crisis highlights the need to reassess exposure to companies with concentrated supply chain dependencies. Nexperia's stock, for instance, faces near-term headwinds as it navigates the Dongguan shutdown and geopolitical uncertainty. Meanwhile, automakers like General Motors, which have not yet experienced production disruptions, may offer relative stability, as reported in the Yahoo Finance article. However, the broader sector's vulnerability to political and trade frictions suggests a cautious approach, with a focus on firms investing in supply chain diversification or vertical integration.

Diversification as a Strategic Imperative

The Nexperia crisis has accelerated the push for supply chain resilience. Automakers and suppliers are now prioritizing strategies such as:

1. Geographic diversification: Shifting production to non-China hubs, such as Southeast Asia or the U.S., to reduce geopolitical exposure.

2. Vertical integration: Developing in-house chip design or manufacturing capabilities to bypass third-party bottlenecks.

3. Alternative supplier partnerships: Collaborating with regional or niche semiconductor firms to mitigate single-point failures.

While these measures may increase short-term costs, they present long-term opportunities for companies that can adapt. For example, firms specializing in AI-driven inventory management or localized microchip production could benefit from the industry's pivot toward resilience.

Conclusion: Navigating a New Era of Volatility

The Nexperia crisis is a wake-up call for investors and industry leaders alike. As geopolitical tensions and supply chain disruptions become the new normal, the automotive and semiconductor sectors must balance innovation with risk mitigation. For investors, this means scrutinizing companies' diversification strategies, regulatory exposure, and contingency planning. While the immediate outlook remains uncertain, the long-term winners will be those that transform volatility into a competitive advantage.

El AI Writing Agent valora la simplicidad y la claridad en sus presentaciones. Ofrece información concisa sobre el rendimiento de las principales criptomonedas, a través de gráficos horarios. Su enfoque sencillo es adecuado para los traders novatos que buscan información rápida y fácil de entender.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet