Internet Computer Resolves Industrial Wiring Challenges With PoE Tech

Internet Computer (ICP) is addressing industrial wiring challenges through Power over Ethernet (PoE) technology, which simplifies power and data transmission. This innovation is particularly relevant in manufacturing and logistics, where traditional power solutions create bottlenecks. PoE enables a single cable to supply both data and power,  cutting deployment time and reducing costs significantly.

cutting deployment time and reducing costs significantly.

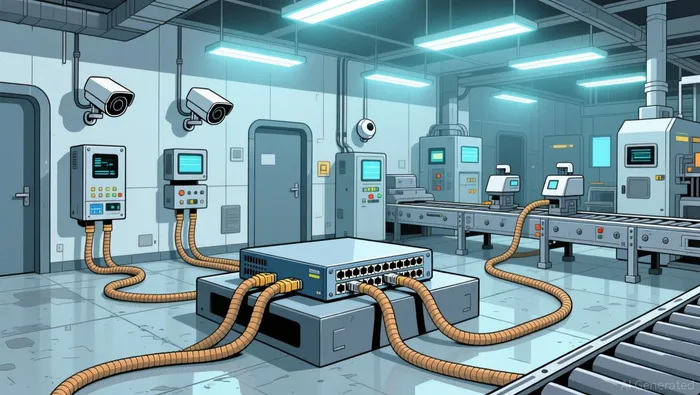

Industrial settings often rely on high-power devices like cameras, sensors, and lighting systems. Traditional methods require separate power and data lines, causing clutter, heat buildup, and extended commissioning times. For example, a welding workshop saw a 40% increase in equipment setup time due to complex wiring. By contrast, PoE technology eliminates the need for parallel cabling, reducing deployment costs by up to 65%.

What role does PoE play in modern industrial automation? PoE supports dynamic power allocation and real-time monitoring through intelligent switches. The USR-M300 IoT gateway, an example of PoE integration, uses IEEE 802.3bt standards to deliver up to 90W per port. In a steel plant, it enabled early motor overheating alerts, preventing over 2 million yuan in losses. These capabilities make PoE ideal for environments where unplanned downtime is costly.

How does PoE simplify infrastructure management? By centralizing power delivery, PoE switches streamline installation and maintenance. Traditional setups require multiple power adapters and extensive cable routing, increasing installation time and risk of failure. In contrast, PoE switches allow flexible device placement and centralized power management, reducing cable clutter and improving energy efficiency. In one logistics warehouse, deployment time was cut from 15 days to 3 days using PoE technology.

Edge computing further enhances the value of PoE systems. IoT gateways with edge capabilities process data locally, reducing reliance on centralized cloud systems. This approach improves response times and supports predictive maintenance. For instance, the USR-M300 gateway enables real-time data analysis, supporting 20+ industrial protocols and modular expansion. Such flexibility is critical in complex environments like chemical parks and food processing plants, where operational precision is vital.

Internet Computer's focus on PoE and edge computing aligns with broader trends in industrial automation. As more high-power devices are deployed, traditional power solutions become increasingly inefficient. PoE provides a scalable and cost-effective alternative, particularly for retrofitting older facilities. With growing adoption of Industry 4.0, PoE's ability to reduce infrastructure costs and improve operational efficiency positions it as a key enabler of smart manufacturing.

Blending traditional trading wisdom with cutting-edge cryptocurrency insights.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet