The Impact of the 2025 Great Lakes Shredded Cheese Recall on Food Retail and Consumer Safety Sectors

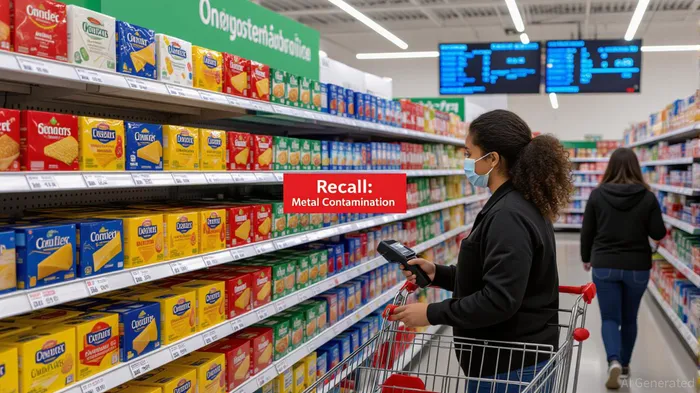

The 2025 Great Lakes Shredded Cheese Recall, , WalmartWMT--, and TargetTGT--, has exposed critical vulnerabilities in the food retail supply chain while reshaping investor risk assessments. This recall, initially voluntary but later reclassified as a Class II event by the FDA due to potential metal fragment contamination, underscores the fragility of supplier-dependent production models and the urgent need for resilience strategies in an era of heightened consumer safety expectations

according to the report.

Supply Chain Vulnerabilities and Resilience Strategies

The recall originated from contamination in raw materials supplied to Great Lakes Cheese Co., a supplier to multiple retailers. This highlights a systemic risk: over-reliance on single-source suppliers for high-volume, low-margin products.

According to a report by the FDA, the incident emphasizes the importance of supplier vetting, real-time quality monitoring, and contingency planning.

Retailers are now recalibrating their supply chain strategies. Walmart, for instance, has accelerated its investment in AI-driven inventory systems, including "Self-Healing Inventory" technology, which automatically reroutes overstocked products to stores in need, reducing waste and ensuring stock availability

according to corporate news. Aldi, known for its private-label efficiency, is leveraging localized supplier networks to maintain cost control and product consistency, a strategy that mitigates disruptions from distant supply chains

as business analysis shows. Target, while less detailed in its post-recall adjustments, faces growing pressure to adopt digital traceability tools and sustainability initiatives to align with evolving risk management standards

as research indicates.

These strategies reflect a broader shift toward diversification, transparency, and technological integration. For example, Walmart's Proactive and Predictive Warehouse and Transportation Management Systems now enable real-time coordination of fulfillment, optimizing delivery routes to maintain product quality

according to corporate announcements. Such innovations are critical for minimizing future disruptions and restoring consumer trust.

Investor Risk Assessments and Market Implications

The recall has intensified investor scrutiny of food retail supply chains. While no widespread injuries were reported, . states and Puerto Rico-has raised concerns about reputational damage, operational costs, and regulatory penalties.

Analysts note that retail inventory accuracy, , could worsen post-recall, compounding risks.

Stock price reactions, though not explicitly detailed in available data, are likely influenced by broader market perceptions of corporate risk management.

Stock price reactions, though not explicitly detailed in available data, are likely influenced by broader market perceptions of corporate risk management.

A case study highlights that companies failing to adapt to such crises face prolonged investor skepticism. For Aldi, Walmart, and Target, the recall serves as a stress test for their ability to balance cost efficiency with safety protocols-a balance that directly impacts shareholder confidence.

Investor reports also emphasize the indirect costs of recalls, including lost sales, inventory write-offs, and the logistical burden of managing returns. The FDA's reclassification of the recall to Class II

amplified urgency for retailers, forcing them to address customer inquiries, refunds, and shelf restocking while navigating potential legal liabilities. These pressures are likely to influence quarterly earnings and long-term capital allocation decisions.

Conclusion: Lessons for Resilience and Risk Mitigation

The 2025 Great Lakes Shredded Cheese Recall is a wake-up call for the food retail sector. It underscores the necessity of embedding resilience into supply chains through supplier diversification, advanced monitoring technologies, and agile inventory systems. For investors, the incident highlights the importance of evaluating corporate preparedness for such disruptions, as operational efficiency and brand reputation are inextricably linked.

As retailers like Walmart and Aldi demonstrate, proactive adaptation-whether through AI-driven logistics or localized sourcing-can mitigate risks and reinforce investor confidence. However, the absence of concrete stock price data post-recall suggests that the full financial impact remains to be seen. What is clear is that the era of passive supply chain management is over; resilience is now a non-negotiable component of competitive advantage in the food retail landscape.

Tracking the pulse of global finance, one headline at a time.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet