Fluor and the Tariff-Driven U.S. Pharma Construction Renaissance

The U.S. pharmaceutical industry is at a pivotal inflection point. With the Trump administration's impending 100% tariff on imported branded and patented drugs—effective October 1, 2025—companies face a stark choice: reshore manufacturing or absorb steep costs. This policy, framed as a national security imperative, has already triggered a surge in domestic construction projects, creating a golden opportunity for engineering and construction (E&C) firms like Fluor CorporationFLR--. By examining Fluor's recent contracts, strategic alignment with industry trends, and the broader implications of tariff-driven reshoring, investors can assess its positioning in a sector poised for rapid transformation.

Tariffs as a Catalyst for Domestic Reshoring

The tariff regime, announced in late 2025, mandates that pharmaceutical firms either begin constructing U.S. manufacturing plants by the deadline or face prohibitive import costs. This has spurred a wave of capital expenditures, particularly for active pharmaceutical ingredient (API) and biologics facilities. For instance, Eli Lilly and Johnson & Johnson have accelerated domestic projects to secure tariff exemptions. According to a report by the Kenan Institute of Private Enterprise, the policy aims to reduce reliance on foreign supply chains while bolstering domestic job creation. However, critics warn of unintended consequences, including higher drug prices for consumers and reduced R&D investment as firms divert funds to construction.

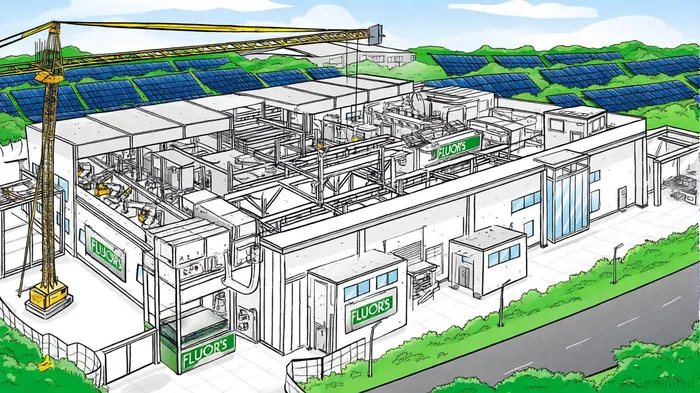

Fluor's Strategic Positioning in the Pharma Renaissance

Fluor has emerged as a key beneficiary of this reshoring surge. The firm's recent projects underscore its leadership in pharmaceutical construction:

1. Bayer's Biotech Campus in California: FluorFLR-- delivered a LEED v4 Platinum-certified facility in Berkeley, featuring 30,000 square feet of cleanroom space for cell therapy production. This project, completed in 2025, highlights Fluor's expertise in advanced manufacturing and sustainability—a critical differentiator in an industry increasingly prioritizing environmental, social, and governance (ESG) metrics.

2. Indiana API Facility: Fluor secured a multi-billion-dollar EPCM contract for a facility in Lebanon, Indiana, dedicated to producing peptide-based drugs for diabetes and weight management. This project, described as the largest U.S. API investment in history, aligns with the administration's goal of strengthening domestic supply chains.

3. Global Expansion: While the tariff focus is domestic, Fluor's work on a biologics plant in Denmark for Fujifilm Diosynth Biotechnologies (valued at hundreds of millions) demonstrates its ability to scale expertise across geographies. This diversification mitigates risks tied to U.S. policy shifts.

Data from Fluor Lands Historic Pharma Facility Contract highlights a 40% year-over-year increase in pharma-related revenue in 2025, driven by these projects. The firm's EPCM (engineering, procurement, and construction management) model, which emphasizes cost control and efficiency, is particularly well-suited to the high-stakes, time-sensitive nature of pharmaceutical construction.

Industry Dynamics and Fluor's Competitive Edge

The pharmaceutical construction sector is characterized by high barriers to entry, including stringent regulatory requirements (e.g., FDA and EMA compliance) and the need for specialized cleanroom technology. Fluor's track record in delivering complex, large-scale projects—such as its 2021 work on Bayer's Single Use Technology Center—positions it ahead of competitors like Bechtel and AECOM. Moreover, its integration of digital tools, such as Building Information Modeling (BIM), enhances project predictability, a critical factor for pharmaceutical clients operating under tight deadlines.

However, challenges persist. The industry's reliance on global supply chains means delays in equipment or material sourcing could impact Fluor's timelines. Additionally, while tariffs incentivize reshoring, they also risk inflating drug prices, potentially leading to political backlash or regulatory adjustments. Fluor's ability to navigate these uncertainties will depend on its agility in adapting to evolving policy landscapes and maintaining strong client relationships.

Investment Implications

For investors, Fluor represents a compelling play on the intersection of policy-driven demand and operational expertise. The firm's recent contracts suggest robust near-term visibility, with the Indiana API project alone expected to generate revenue over multiple years. Furthermore, its alignment with ESG trends—evidenced by the LEED-certified Bayer facility—could attract capital from sustainability-focused funds.

Conclusion

The U.S. pharmaceutical industry is undergoing a structural shift, driven by tariffs that force companies to choose between reshoring or paying exorbitant import costs. Fluor, with its deep expertise in pharma construction, strategic project portfolio, and ESG-aligned execution, is well-positioned to capitalize on this inflection point. While risks such as supply chain bottlenecks and political volatility remain, the firm's proactive engagement with industry leaders and government stakeholders suggests a resilient path forward. For investors seeking exposure to a sector at the nexus of policy and innovation, Fluor offers a compelling case study in strategic positioning.

Senior strategist with 20+ years experience delivering data-driven research, ETF and stock analysis, and practical investment ideas.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet