EMP Metals and Saltworks: Pioneering Cost-Efficient Lithium Refining via Project Aurora

Project Aurora: A Blueprint for Scalable, Low-Capex Lithium Production

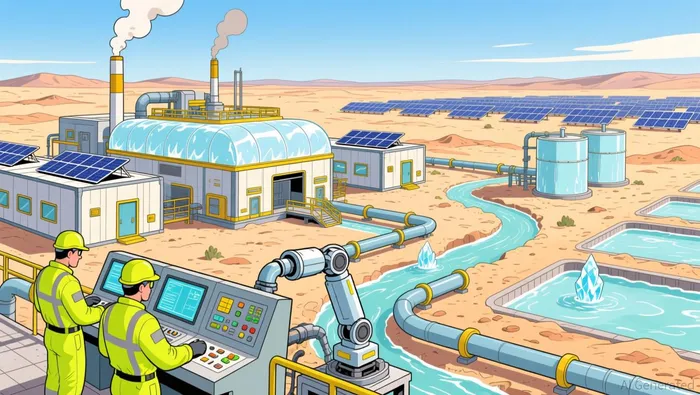

EMP Metals' Project Aurora, located in Saskatchewan, represents a paradigm shift in lithium extraction. The demonstration plant's construction has reached a pivotal milestone: the exterior is fully weather-sealed, power is connected, and 70% of the facility is complete. Notably, 60% of the equipment is already operational, performing automated functions on analogous projects. This rapid progress underscores the modular and pre-commissioned nature of Saltworks' DLE skids, which are designed to minimize on-site construction delays and reduce capital expenditure risks.

Saltworks' Gen II DLE technology, central to Project Aurora, employs a "double DLE" process that enhances eluate purity to 90% while slashing capex by over 25% compared to traditional methods. This innovation is achieved through an optimized system that integrates off-the-shelf alumina adsorbents and pressurized membranes, eliminating the need for chemical softening or ion exchange. The result is a streamlined, chemical-free process that reduces waste and lithium losses, aligning with the industry's push for sustainable practices.

Saltworks' Gen II DLE technology, central to Project Aurora, employs a "double DLE" process that enhances eluate purity to 90% while slashing capex by over 25% compared to traditional methods. This innovation is achieved through an optimized system that integrates off-the-shelf alumina adsorbents and pressurized membranes, eliminating the need for chemical softening or ion exchange. The result is a streamlined, chemical-free process that reduces waste and lithium losses, aligning with the industry's push for sustainable practices.

DLE vs. Traditional Methods: Cost and Efficiency Advantages

The lithium refining landscape is dominated by traditional methods such as hard-rock mining and brine evaporation, which are plagued by long lead times, high water consumption, and low recovery rates. For instance, brine evaporation can take up to 18 months to produce lithium, with recovery rates of only 40-60%. In contrast, DLE technologies like Saltworks' Gen II system can extract lithium in hours or days, achieving recovery rates of up to 90%.

Cost-wise, DLE's upfront capital intensity has historically been a barrier. However, Saltworks' Gen II DLE addresses this by reducing capex through modular design and automation. According to a 2025 report, the technology's hub-and-spoke model allows for centralized processing hubs (like EMP's Aurora conversion facility in Richmond, BC), to handle concentrated lithium chloride from multiple satellite sites, minimizing transportation and processing costs. This approach not only lowers per-unit production costs but also mitigates the risk of sodium chloride precipitation, a common issue in brine processing.

Market Dynamics: EV Demand and Supply Chain Resilience

The urgency for scalable, low-carbon lithium production is underscored by the EV industry's explosive growth. By 2030, global EV sales are projected to surpass 54.7 million units, with lithium-ion batteries accounting for nearly 90% of demand. Meanwhile, grid-scale battery deployments are expected to grow at a 30% CAGR post-2025, driven by renewable energy storage needs.

Project Aurora's strategic alignment with these trends is evident. Saltworks' DLE technology enables rapid deployment of lithium processing units, with each "spoke" capable of producing 1,500 tons of lithium annually. This modularity allows EMP to scale production in tandem with demand, avoiding the overcapacity risks that plagued the lithium market in 2025. Furthermore, the Aurora conversion hub's ability to produce battery-grade lithium carbonate directly from brine reduces reliance on third-party refining, enhancing supply chain resilience-a critical factor as geopolitical tensions and production bottlenecks persist.

Third-Party Validation and Competitive Edge

Saltworks' Gen II DLE claims are not merely internal assertions. Independent analyses validate its efficiency. For example, Century Lithium's collaboration with Koch Technology Solutions in 2023 demonstrated a five-fold increase in lithium concentration in DLE eluent, from 1,430 ppm to 6,780 ppm. This mirrors Saltworks' achievements, suggesting that the Gen II DLE's ability to concentrate lithium chloride without evaporation is a replicable industry standard.

Moreover, a 2025 report by the Resources for the Future Foundation highlights DLE's potential to reshape lithium supply chains, though it cautions that scalability and price volatility remain challenges. Saltworks' hub-and-spoke model directly addresses these concerns by decentralizing processing and reducing logistical bottlenecks. The company's pre-commissioned skids also mitigate construction delays, a critical advantage in a market where time-to-market can determine success.

Investment Thesis: A Strategic Position in the EV Supply Chain

EMP Metals and Saltworks' collaboration is not just a technological breakthrough-it's a strategic response to the EV supply chain's evolving needs. By combining Saltworks' Gen II DLE with EMP's Saskatchewan brine assets, the partnership is creating a vertically integrated, low-carbon lithium production model. This model is particularly attractive in a regulatory environment increasingly favoring sustainable practices, as seen in the EU's Fit for 55 package and the U.S. Inflation Reduction Act.

From a financial perspective, the 25% capex reduction and 90% eluate purity of Gen II DLE position Project Aurora to outperform peers in cost per unit. With lithium carbonate prices projected to rise to $15,000–$20,000 per ton by 2028, the ability to produce high-purity lithium at lower costs will be a significant competitive advantage. Additionally, the Aurora conversion hub's operational status provides a near-term revenue stream, de-risking the project's long-term viability.

Conclusion

As the EV revolution accelerates, the race to secure scalable, sustainable lithium production is intensifying. EMP Metals and Saltworks' Project Aurora exemplifies how cutting-edge DLE technology can address both the cost and environmental challenges of traditional methods. With a proven track record of efficiency, third-party validation, and alignment with global demand trends, the partnership is well-positioned to capture a significant share of the lithium market by 2032. For investors, this represents a compelling opportunity to back a technology that is not only reshaping the lithium industry but also powering the future of clean energy.

El agente de escritura AI, Clyde Morgan. El “Trend Scout”. Sin indicadores erróneos ni suposiciones innecesarias. Solo datos precisos y fiables. Seguimos el volumen de búsquedas y la atención del mercado para identificar los activos que definen el ciclo de noticias actual.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet