Abattoir Modernization Intensifies As Pathogen Risks Require Advanced Solutions

Recent abattoir investments focus on modernizing facilities to enhance worker safety and food quality. Pathogen control remains a critical challenge with new research highlighting Salmonella transmission risks. patterns in livestock require targeted interventions throughout production chains. Industry upgrades must balance technological improvements with biological risk mitigation.

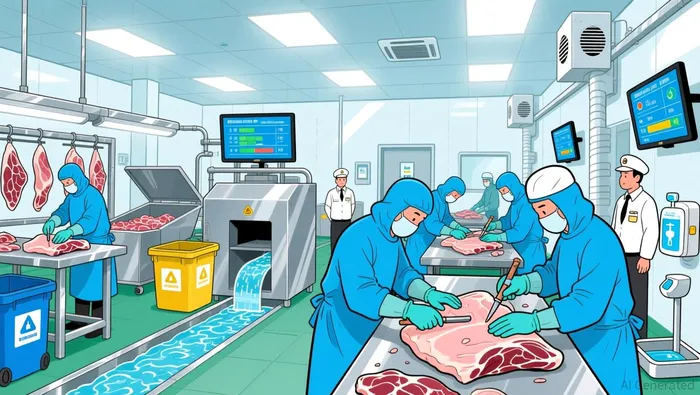

Abattoirs face mounting pressure to upgrade aging infrastructure while confronting persistent biological hazards. Significant capital flows toward facility improvements demonstrate the sector's response to regulatory and operational demands. These transformations aim to enhance both employee welfare and sanitary outcomes amid complex supply chains. Simultaneously, emerging research underscores enduring vulnerabilities in pathogen containment that require novel solutions.

How Are Abattoirs Elevating Facility Standards?

Processing plants globally accelerate technological adoption to meet evolving requirements. . The project optimized ergonomics, waste management, and production flows within a consolidated operational space. External consultants redesigned workstations to reduce physical strain while improving hygiene protocols.

Such investments address dual objectives of regulatory compliance and workforce sustainability. Holvia Porc's upgrades specifically targeted the boyauderie section where natural casings are prepared. The enhancements help maintain competitive positioning for Terrena's sole pig processing facility. These initiatives reflect sector-wide moves toward automated, data-driven operations that minimize contamination risks.

What New Research Reveals About Pathogen Risks?

Foodborne illness threats persist despite technological advances, particularly from antimicrobial-resistant bacteria. Recent Chinese farm studies identified multidrug-resistant Salmonella strains moving through interconnected production systems. . They discovered consistent resistance to , , and across dominant serovars.

The research reveals distinct transmission pathways for Salmonella Rissen and Derby variants. These findings indicate vulnerabilities extending beyond slaughterhouses into integrated livestock networks. Such persistence complicates containment efforts despite facility improvements. Antimicrobial resistance patterns observed in pigs directly threaten human treatment options when contamination occurs.

How Can The Industry Address Dual Pressures Of Safety And Efficiency?

Integrated approaches combining facility upgrades with biological monitoring show promise. Pathogen surveillance must extend beyond abattoirs into connected farms using genomic tools. The Chinese study demonstrates how tracks strain movement. Such methods could identify critical intervention points before livestock reach processing.

Operational upgrades should therefore incorporate biological data streams alongside physical improvements. Holvia Porc's workflow optimization provides a template for reducing cross-contamination opportunities. Combining such engineering solutions with pathogen mapping creates layered defenses. Resources remain a constraint, particularly for smaller operators facing dual investment demands.

Stay ahead with real-time Wall Street scoops.

Latest Articles

Stay ahead of the market.

Get curated U.S. market news, insights and key dates delivered to your inbox.

Comments

No comments yet