Volkswagen's Production Adjustments at Zwickau and Emden: Implications for EV Supply Chain Resilience and Near-Term Profitability

Volkswagen's strategic recalibration of its electric vehicle (EV) production at Zwickau and Emden has become a focal point for investors assessing the automaker's ability to navigate the turbulent transition to electrification. Recent adjustments, including temporary shutdowns, workforce reductions, and model reallocations, underscore the company's struggle to balance supply chain constraints, shifting demand dynamics, and profitability pressures. This analysis evaluates the implications of these moves for Volkswagen's EV supply chain resilience and near-term financial health, drawing on the latest data and strategic disclosures.

Production Adjustments: A Response to Bottlenecks and Weak Demand

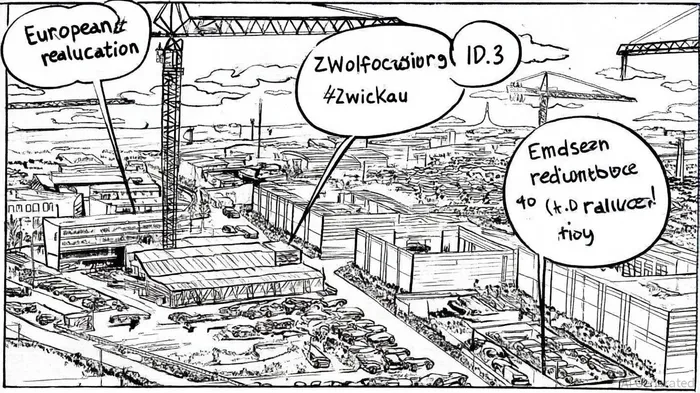

Volkswagen's Zwickau plant, once a flagship EV hub, has faced repeated disruptions due to a critical bottleneck in the supply of the new APP550 electric motor. According to a report by Electrive, production line 2 at Zwickau was paused in early 2025 due to delays at the Kassel components plant, which supplies these motors[2]. This shortage, combined with weak demand for models like the Audi Q4 e-tron and ID.3, has forced Volkswagen to reallocate production. By Q3 2025, Zwickau will lose the ID.3 and Cupra Born to Wolfsburg, while the ID.4 shifts to Emden, leaving the plant with only one production line for the Audi Q4 e-tron[5].

Emden, in contrast, has maintained full capacity, producing the ID.4, ID.7, and ID.7 Tourer. However, the plant has also cut employee hours, reflecting broader cost-cutting measures[1]. These adjustments highlight Volkswagen's prioritization of flexibility: shifting production to plants with higher capacity while reducing overcapacity elsewhere.

Financial Implications: A 42% Drop in Operating Profit

The production pauses and restructuring efforts have directly impacted Volkswagen's profitability. In Q3 2025, the company reported a 42% decline in operating profit to €2.86 billion, driven by high costs from model revamps, U.S. tariffs, and weak demand in key markets like China[3]. The core Volkswagen brand's operating margin fell from 3.4% to 2.1% in the first nine months of 2025, according to InsideEVs[3].

Restructuring costs further exacerbated the decline. The Volkswagen Group incurred €0.7 billion in restructuring expenses across Audi, Volkswagen Passenger Cars, and Cariad in H1 2025[6]. These costs, combined with CO₂ regulation penalties and U.S. import tariffs, contributed to a 33% drop in operating profit year-on-year to €6.7 billion for the first half of 2025[4].

Supply Chain Resilience: Progress and Persistent Challenges

Volkswagen's supply chain strategy post-December 2024 has focused on diversification and digitalization. The company has adopted a dual-supplier approach and localized its supplier portfolio for core EV components, reducing reliance on single sources[1]. Additionally, the integration of Catena-X, a data-sharing platform for the automotive industry, has improved transparency and risk identification[1].

Despite these efforts, challenges persist. Natural disasters in Central and Eastern Europe disrupted supply chains in 2024, forcing temporary production cuts[2]. Geopolitical risks, such as U.S. tariffs and regulatory shifts in Germany, remain significant headwinds[3]. Volkswagen's CFO, Arno Antlitz, acknowledged that the EV transition is “more costly and less profitable” than traditional combustion engines, necessitating further cost discipline[2].

Cost-Cutting and Future Outlook

To address profitability gaps, Volkswagen has announced aggressive cost-cutting measures. The Zwickau plant will not renew contracts for 1,000 temporary workers by 2025, while Emden has reduced shift hours[5]. The company aims to save €10 billion by 2026 through factory closures, workforce reductions, and operational streamlining[2].

Long-term, Volkswagen remains committed to electrification. The Salzgitter battery hub, producing standardized cells for volume segments, is set to launch in 2025[1]. The company also plans to launch over 70 EV models by 2025 and achieve 1.5 million annual EV sales by 2030[3]. However, these ambitions hinge on resolving current supply chain and demand challenges.

Conclusion: A Delicate Balancing Act

Volkswagen's production adjustments at Zwickau and Emden reflect a strategic pivot to align with market realities. While these moves aim to enhance supply chain resilience and reduce overcapacity, they come at the cost of near-term profitability. Investors must weigh the company's progress in digitalization and diversification against ongoing challenges like weak demand and geopolitical risks. For Volkswagen to succeed in its EV ambitions, it must not only stabilize its production network but also restore confidence in its ability to deliver sustainable margins in a rapidly evolving industry.

Comentarios

Aún no hay comentarios