Voestalpine AG: Pioneering Decarbonization and Industrial Resilience in the Steel Sector

The global steel industry stands at a crossroads, grappling with the dual pressures of decarbonization and economic competitiveness. For investors, identifying companies that can navigate this transition while maintaining profitability is critical. Voestalpine AG (VLPNY), the Austrian industrial giant, has emerged as a standout player in this arena. Following its 2025 Investor Day, the company has laid out an ambitious roadmap that positions it as a leader in decarbonization while reinforcing its long-term industrial resilience.

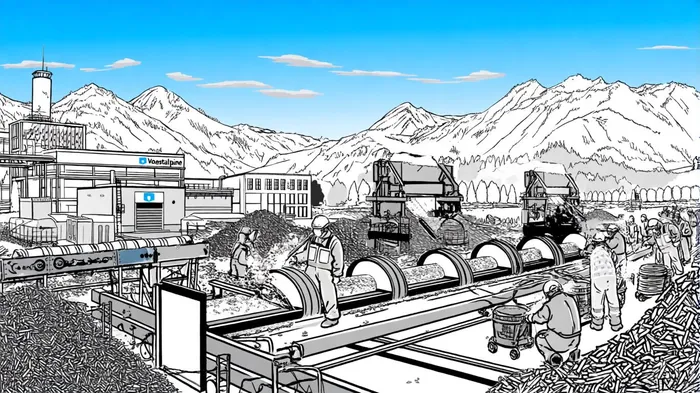

Strategic Decarbonization: A Blueprint for Net-Zero Steel

Voestalpine's sustainability report initiative is the cornerstone of its decarbonization strategy. The company plans to replace two coal-dependent blast furnaces with electric arc furnaces (EAFs) at its Linz and Donawitz sites, a EUR 1.5 billion investment that will reduce CO₂ emissions by up to 30% by 2030 compared to 2019 levels, according to the company's capital allocation information. This transition is part of a phased approach to achieve 52% decarbonized output by 2027 and full net-zero emissions by 2050, as outlined in its Q3 2025 earnings. By 2025, the company has already allocated EUR 110 million to this project, demonstrating early execution and commitment.

What sets Voestalpine apart is its integration of multiple decarbonization levers. The company is not only electrifying its production but also securing long-term supplies of DRI and HBI to feed its EAFs, as reported by MarketScreener. Additionally, it is investing in hydrogen-based technologies like HYFOR and SuSteel, highlighted in the E3G scorecard, which could further diversify its low-carbon input materials. This multi-pronged strategy aligns with the Science Based Targets initiative (SBTi) and the Paris Agreement, with intermediate goals such as a 50% reduction in CO₂ emissions for its High Performance Metals division by 2029, noted in the company's press release.

Industry Leadership in a Fragmented Landscape

The steel sector's decarbonization efforts remain uneven, as discussed in an EAF mill perspective. While European countries like Germany and the UK have shown policy ambition, delivery of near-zero emissions projects lags due to high hydrogen prices, regulatory uncertainty, and fragmented supply chains. For example, EAF-based producers-though less carbon-intensive than blast furnace operations-face challenges such as volatile electricity costs (ranging from €20 to €200 per MWh) and limited access to low-copper scrap; Voestalpine has partly addressed financing constraints by securing a €300 million EIB loan.

Voestalpine's approach addresses these pain points head-on. By using that EIB financing to accelerate R&D in green steel production and optimize energy efficiency, the company is strengthening its position; market uptake is reflected in increased demand for its CO2-reduced premium steel. Its use of ISO 14001/EMAS-certified environmental management systems across production facilities further strengthens its operational resilience, as reported by Reuters. Moreover, the company's advocacy for policy frameworks-such as extending free emissions trading certificates beyond 2034 and fair treatment under the Carbon Border Adjustment Mechanism-positions it as a proactive shaper of the regulatory environment.

Financial Resilience and Strategic Growth

Beyond decarbonization, Voestalpine's capital allocation strategy reinforces its long-term viability. The company targets a return on capital employed (ROCE) of over 12% and an EBITDA margin of 14%, supported by disciplined cost management and a shareholder-friendly dividend policy (30% payout ratio, minimum EUR 0.40 per share). Its "local-for-local" production strategy-expanding manufacturing in high-potential markets like North America and Asia-reduces exposure to tariffs and enhances supply chain efficiency.

Critically, Voestalpine is already monetizing its green steel offerings. The company supplies CO₂-reduced steel to 35 customers across wind energy, construction, and consumer goods, with emissions reductions of up to 10% compared to traditional methods. This early market traction not only diversifies revenue streams but also aligns with growing corporate demand for sustainable materials.

Risks and the Path Forward

Despite its strengths, Voestalpine faces headwinds. High electricity costs in Europe and global competition from lower-cost producers could strain margins. However, the company's phased decarbonization approach-prioritizing life-cycle cost analyses and regulatory alignment-mitigates these risks. Additionally, its focus on circular economy principles, such as increasing scrap usage by 50% by 2030, enhances resource efficiency.

Conclusion: A Model for the Future of Steel

Voestalpine's strategic clarity, financial discipline, and technological innovation position it as a leader in the decarbonization race. While the steel industry's transition remains challenging, the company's proactive engagement with policy, technology, and market trends creates a compelling case for long-term investors. As global demand for green steel accelerates, Voestalpine's greentec steel program is not just an environmental imperative-it's a competitive advantage.

Comentarios

Aún no hay comentarios