Thailand's Automotive Sector Slowdown and Its Implications for Regional EV Supply Chains

The Thai automotive industry, once a cornerstone of Southeast Asia's manufacturing prowess, is grappling with a profound slowdown in 2025. A global shift toward electric vehicles (EVs) has disrupted traditional production models, displacing over 100,000 workers and reducing car output by 15% year-on-year[1]. This transition, while inevitable, has exposed vulnerabilities in Thailand's supply chain resilience, particularly for small and medium-sized enterprises (SMEs) struggling to adapt to digitalization and green technologies[1]. Yet, amid the challenges, Thailand's EV market is projected to grow by 40% in 2025, driven by government incentives such as tax breaks for plug-in hybrids and subsidies of up to 150,000 baht per vehicle[4]. This duality—decline in legacy sectors and growth in EVs—raises critical questions about the region's long-term investment potential in Southeast Asian EV ecosystems.

The Thai Dilemma: Transition Costs and Chinese Competition

Thailand's EV ambitions are anchored in the EV 3.5 policy, which mandates local production targets and offers reduced excise taxes to attract manufacturers[3]. However, the policy's success has been tempered by the influx of Chinese automakers like BYD and Great Wall Motor, which dominate 70% of the EV market[1]. These firms leverage aggressive pricing strategies, with some models discounted by over 270,000 baht, triggering a price war that threatens smaller players[3]. While Chinese battery producers such as CATL and Gotion High-tech are expanding in Thailand, their integration into local supply chains remains limited, raising concerns about overreliance on foreign ecosystems[2].

The economic context exacerbates these challenges. Thailand's household debt-to-GDP ratio exceeds 90%, and a cautious lending environment has dampened consumer demand[4]. These factors, combined with a 20-month decline in overall vehicle production[4], underscore the fragility of Thailand's transition. Yet, the government's 30% EV production target by 2030[4] signals a commitment to long-term transformation, albeit one that hinges on balancing foreign investment with domestic industrial capacity.

Regional Resilience: ASEAN's Diversified EV Ecosystem

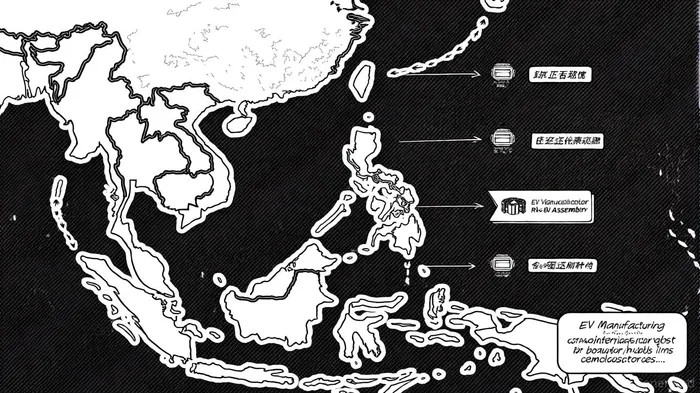

Beyond Thailand, Southeast Asia is recalibrating its EV supply chains to mitigate risks and capitalize on regional strengths. Indonesia, for instance, is leveraging its 40% global nickel reserves to build a battery manufacturing hub, with LG Energy Solution and CATL investing in downstream processing[5]. The country's ban on raw ore exports and 80% domestic component ratio by 2030[5] aim to secure a competitive edge in battery production. Vietnam, meanwhile, is emerging as a dual hub for EVs and semiconductors, with VinFast scaling production from 97,000 units in 2024 to 500,000 by 2028[5]. Intel and Amkor's investments in semiconductor testing and packaging further solidify Vietnam's role in the EV value chain[5].

Malaysia and the Philippines are also contributing to the regional ecosystem. Malaysia's Penang has evolved into a design and R&D hub for EV electronics[5], while the Philippines is pioneering battery swapping infrastructure with nearly 500 stations operational[5]. ASEAN's strategic alignment, including initiatives like the ASEAN Framework for Integrated Semiconductor Supply Chain (AFISS), aims to harmonize policies and create Special Economic Zones (SEZs) that co-locate semiconductor, battery, and EV assembly operations[5].

Investment Potential: Navigating Risks and Opportunities

The Southeast Asian EV landscape presents a mix of risks and opportunities for investors. On one hand, Thailand's slowdown highlights the sector's susceptibility to global transitions and economic volatility. On the other, the region's mineral endowments, growing semiconductor capabilities, and policy alignment offer a robust foundation for long-term growth. KPMG forecasts a 17.7% compound annual growth rate in battery electric vehicle (BEV) sales in Thailand, rising from 92,576 units in 2023 to 290,000 by 2030[5]. Similarly, Indonesia's 20% electrification target for new vehicles by 2025[5] and Vietnam's rapid EV sales growth suggest strong regional momentum.

However, challenges persist. Infrastructure gaps, talent shortages, and fragmented policies could hinder progress. For instance, Thailand's 12,000 DC fast-charging station target by 2030[3] requires significant capital, while Vietnam's battery recycling systems remain underdeveloped[5]. Investors must also weigh the risks of overreliance on Chinese supply chains, as seen in Thailand's EV market[1], against the potential for regional collaboration to diversify dependencies.

Conclusion: A Path Forward

Thailand's automotive sector slowdown is a cautionary tale of the costs of transition, but it also underscores the urgency of regional integration. ASEAN's collective push to align EV standards, develop cross-border supply chains, and invest in human capital[5] positions the region as a formidable player in the global EV market. For investors, the key lies in balancing short-term risks—such as Thailand's economic headwinds—with long-term opportunities in Indonesia's battery sector, Vietnam's semiconductor growth, and Malaysia's R&D capabilities. As the region navigates this transformation, the ability to adapt to evolving policies and technological shifts will determine the resilience of Southeast Asia's EV ecosystems.

Comentarios

Aún no hay comentarios