Tata Steel's Strategic Resilience in a Volatile Commodity Era: A Defensive-Growth Play in the Making

In an era marked by global commodity volatility, geopolitical uncertainties, and shifting demand dynamics, Tata Steel stands out as a rare blend of defensive resilience and growth potential. The company's strategic initiatives-spanning cost optimization, backward integration, and capacity expansion-position it to navigate headwinds while capitalizing on India's robust steel demand. For investors seeking long-term value, Tata Steel's approach offers a compelling case for a defensive-growth play.

Cost Control: A Foundation for Resilience

Tata Steel's cost-control measures are not merely reactive but part of a broader, multi-year transformation. The company has set an ambitious target of achieving ₹11,500 crore ($1.3 billion) in cost reductions globally by FY2026, with ₹4,000 crore earmarked for India operations according to its CFO. These savings stem from operational efficiency gains, including reduced conversion costs (₹1,000–1,200 per tonne) and supply chain rationalization. For instance, the Shikhar25 program, launched in FY2024–25, already delivered ₹6,600 crore in cost takeouts, with ₹2,800 crore from India alone as reported in the 2024–25 integrated report. Such disciplined cost management ensures margin stability amid fluctuating raw material prices and currency pressures.

The UK and Netherlands operations further underscore this focus. Fixed costs in the UK dropped from £995 million in FY2024 to £762 million in FY2025, with a target of £540 million by FY2026. Similarly, the Netherlands' IJmuiden plant aims for €500 million in savings through production optimization and maintenance efficiency according to reports. These efforts reflect a global commitment to operational excellence, a critical differentiator in a cyclical industry.

These efforts reflect a global commitment to operational excellence, a critical differentiator in a cyclical industry.

Backward Integration: Securing Supply Chain Resilience

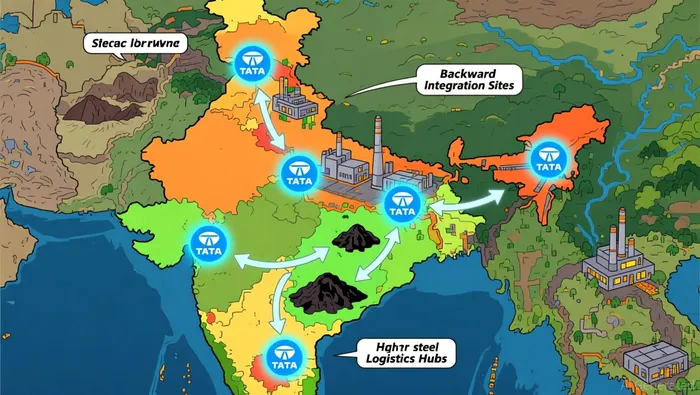

Tata Steel's backward integration strategy addresses a perennial challenge in the steel sector: raw material volatility. The company's greenfield 6 million tonne plant in Gadchiroli, Maharashtra, is a cornerstone of this approach. By collaborating with Lloyd Metals & Energy, Tata Steel is developing an integrated iron ore hub, encompassing mining, pellet production, and logistics. This vertical integration reduces reliance on external suppliers and insulates the company from price shocks, a critical advantage as India's domestic iron ore demand is expected to drive higher imports.

Brownfield projects further reinforce this strategy. The 4.8 million tonne expansion at Neelachal Ispat Nigam and the 2.5 million tonne Thin Slab Caster at Meramandali are designed to enhance efficiency and flexibility as per industry analysis. These projects align with Tata Steel's long-term vision of achieving 35–40 million metric tons of crude steel capacity in India by 2030. By securing supply chains and optimizing production, the company is future-proofing its operations against global disruptions.

Capacity Expansion: Aligning with India's Growth Trajectory

India's steel demand is on an upward trajectory, projected to grow at 5–6% annually, reaching 240–260 million metric tons by 2035. Tata Steel is expanding in lockstep with this demand. In Q3 2025, the company's crude steel production hit 5.68 million tons, a 6% year-over-year increase, driven by the commissioning of a 5 MTPA blast furnace at Kalinganagar. By 2030, Tata Steel aims to double its Indian capacity to 40 million tonnes, with projects like the 0.7 million tonne Hot Rolled Pickling and Galvanizing Line in Tarapur catering to the automotive sector.

This expansion is not just about scale but also about diversification. The downstream projects, including the Thin Slab Caster and rolling facilities, position Tata Steel to capture higher-value segments of the market. As India's infrastructure and manufacturing sectors accelerate, the company's capacity to meet both long and flat product demand will be a key growth driver.

India's Steel Demand: A Tailwind for Long-Term Value

The drivers of India's steel demand are both structural and cyclical. Infrastructure investments, renewable energy projects, and defense modernization are set to fuel consumption, with the Indian Steel Association projecting demand to rise from 119.9 million tonnes in 2023–24 to 128.9 million tonnes in 2024–25. Notably, long products (e.g., rebar, structural steel) are expected to outperform flat products, reflecting the construction and infrastructure boom according to industry forecasts.

Tata Steel's strategic alignment with these trends is evident. Its focus on backward integration and capacity expansion ensures it can meet rising demand without compromising margins. Moreover, the company's sustainability goals-net-zero emissions by 2045 and freshwater consumption below 1.5 cubic meters per tonne by 2030-position it to meet evolving ESG standards, a critical factor for global investors.

Conclusion: A Defensive-Growth Play in the Making

Tata Steel's strategic resilience lies in its ability to balance cost discipline, supply chain security, and capacity growth. While global commodity cycles remain volatile, the company's domestic focus and operational rigor provide a buffer. India's steel demand, driven by infrastructure and industrialization, offers a clear growth trajectory. For investors, Tata Steel represents a rare combination: a defensive stock with the potential for outsized returns in a high-growth market.

Comentarios

Aún no hay comentarios