Tariffs and the Labor Market: Assessing the Risks to Corporate Employment in 2026

The U.S. labor market in 2026 is poised at a crossroads, shaped by the lingering effects of 2025's expansive tariff policies. While these measures were initially framed as tools to protect domestic industries, their ripple effects on employment are proving complex and uneven. Strategic workforce planning has emerged as a critical lever for corporations navigating this landscape, with sector-specific vulnerabilities and adaptive strategies defining the contours of labor risk. This analysis examines the interplay between tariffs, corporate responses, and employment outcomes, drawing on recent data and case studies to project 2026's challenges and opportunities.

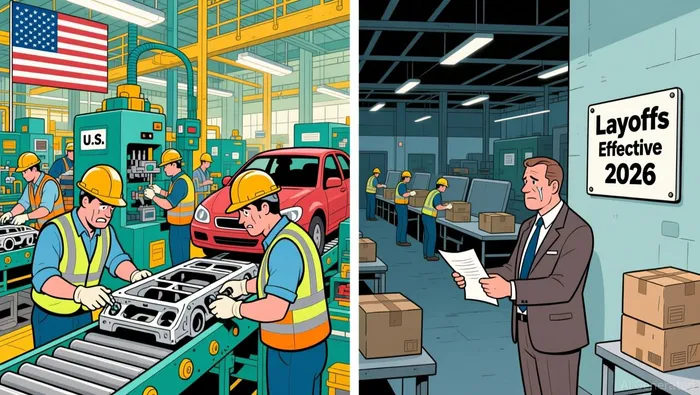

Sector-Specific Employment Dynamics: Winners and Losers

The 2025 tariffs have created a bifurcated labor market, with some sectors experiencing modest gains while others face contraction. According to a report by the Yale Budget Lab, tariff-sensitive manufacturing employment has declined slightly year-to-date but at the same pace as overall manufacturing, suggesting that the labor market effects of tariffs are not yet pronounced. However, industrial output has risen by 3.5%, indicating a nuanced balance between production activity and employment pressures.

Conversely, sectors like healthcare and professional services-less directly impacted by tariffs-have seen employment decelerate or decline, underscoring the indirect effects of trade policy on labor demand according to the Yale Budget Lab. The Tax Foundation's General Equilibrium Model projects a 0.5% reduction in U.S. GDP by 2026 due to tariffs, translating to 503,000 fewer full-time equivalent jobs before retaliatory measures. Sectors such as steel, aluminum, autos, and auto parts are particularly vulnerable, with the auto industry alone expected to lose 103,000 jobs.

Conversely, sectors like healthcare and professional services-less directly impacted by tariffs-have seen employment decelerate or decline, underscoring the indirect effects of trade policy on labor demand according to the Yale Budget Lab. The Tax Foundation's General Equilibrium Model projects a 0.5% reduction in U.S. GDP by 2026 due to tariffs, translating to 503,000 fewer full-time equivalent jobs before retaliatory measures. Sectors such as steel, aluminum, autos, and auto parts are particularly vulnerable, with the auto industry alone expected to lose 103,000 jobs.

Corporate Adaptations: Reskilling, Automation, and Supply Chain Shifts

To mitigate these risks, corporations are recalibrating their workforce strategies. In manufacturing, reshoring efforts are driving demand for skilled labor. A Deloitte report notes that 78% of automotive companies have adjusted production facilities and sourcing strategies in response to tariffs. This shift is accompanied by a surge in reskilling programs, with 94% of industry leaders investing in AI fluency and advanced manufacturing training. For example, GE Aerospace is expanding U.S. factories and hiring 5,000 workers, while Caterpillar Inc. is shifting production to North America to reduce supply chain risks according to industry analysis.

Automation is another key adaptation. The 2026 Manufacturing Industry Outlook highlights that 80% of manufacturers plan to allocate 20% or more of their improvement budgets to smart manufacturing technologies, including agentic AI and cloud computing. These investments aim to offset rising input costs and enhance operational efficiency, though high capital expenditures and limited availability of skilled workers remain constraints.

In logistics, the shift from just-in-time to just-in-case inventory management has increased demand for flexible, contingent labor. Randstad's analysis reveals that 61% of staffing offices anticipate continued stabilization in time-to-fill roles in 2026, driven by the adoption of contract and fractional roles. Meanwhile, automation is accelerating recruitment processes and optimizing production, particularly in packaging and pharmaceutical sectors according to market updates.

Labor Market Projections and Strategic Risks

The 2026 labor market will be defined by sector-specific imbalances. While manufacturing and logistics may see growth in skilled positions, industries with complex global supply chains-such as technology-will lag due to slower adaptation. The Tax Foundation's model projects a 4.5% unemployment rate by 2026, up from 4.3% in late 2025, with retaliatory tariffs potentially exacerbating job losses.

For investors, the risks lie in overreliance on sectors exposed to tariff-driven volatility. The auto and steel industries, for instance, face structural challenges as trade tensions persist. Conversely, opportunities exist in firms leveraging automation and reskilling to future-proof their workforces. Deloitte's research emphasizes that companies prioritizing skills-based hiring and AI integration are better positioned to navigate uncertainty.

Conclusion: Navigating the Tariff-Driven Labor Landscape

The 2026 labor market will reflect the dual forces of trade policy and corporate adaptation. While tariffs have created headwinds for certain sectors, they have also spurred innovation in workforce planning. Investors must weigh the risks of sector-specific contractions against the potential rewards of companies that embrace reskilling, automation, and supply chain resilience. As the U.S. manufacturing sector grapples with rising input costs and geopolitical uncertainty, strategic foresight will be critical to identifying both vulnerabilities and opportunities in a tariff-driven economy.

Comentarios

Aún no hay comentarios