U.S. Submarine Industrial Revival and Critical Minerals: High-Conviction Investment Opportunities in National Security-Driven Defense Spending

The U.S. defense industrial base is undergoing a seismic shift as it races to counter China's growing maritime and technological dominance. With the FY2025 defense budget reaching $851.7 billion-a 12% increase from FY2024-the Navy's submarine industrial base (SIB) and critical mineral supply chains have emerged as focal points of strategic investment. These sectors are not only vital for national security but also represent high-conviction opportunities for investors seeking to capitalize on long-term, government-backed growth.

Defense Spending Trends: Prioritizing Submarine Production and Industrial Resilience

The U.S. Navy's FY2025 shipbuilding budget of $37 billion underscores the urgency of modernizing its submarine fleet. A staggering $3.9 billion is allocated to the SIB, part of an $11.1 billion multi-year plan to address bottlenecks in Columbia- and Virginia-class submarine production[3]. However, systemic challenges persist: 40% of submarines are currently idle due to maintenance delays, and shipyard infrastructure is strained by workforce shortages[2]. To mitigate these risks, the Navy is investing in infrastructure upgrades and workforce development, including a $986 million contract modification for General DynamicsGD-- Electric Boat Corp. to expand joint U.S.-UK submarine programs[1].

Leonardo DRS, a key supplier of propulsion systems, has also secured a $45 million investment to enhance its Goose Creek, South Carolina facility, supporting the Columbia-class electric propulsion systems[3]. Meanwhile, Austal USA's acquisition of Alabama Shipyard aims to boost submarine module production and create 3,000 jobs, aligning with Secretary of the Navy Carlos Del Toro's "Maritime Statecraft" initiative[4]. These investments signal a broader push to scale domestic production capacity, even as unfunded priorities-such as an additional $403 million for SIB projects-highlight the need for further legislative support[2].

Critical Minerals: Securing the Supply Chains Behind Defense Tech

The U.S. is equally focused on insulating its defense supply chains from Chinese dominance in critical minerals. China controls over 80% of rare earth processing and refining, creating a chokepoint for materials essential to submarine electronics, infrared optics, and advanced weaponry[6]. To counter this, the Department of Defense (DoD) has partnered with MP Materials, the sole U.S. rare earth producer, in a $550 million equity and loan package. This includes a 10-year price floor of $110/kg for neodymium-praseodymium (NdPr) and a 100% offtake commitment for magnets, ensuring market stability[1].

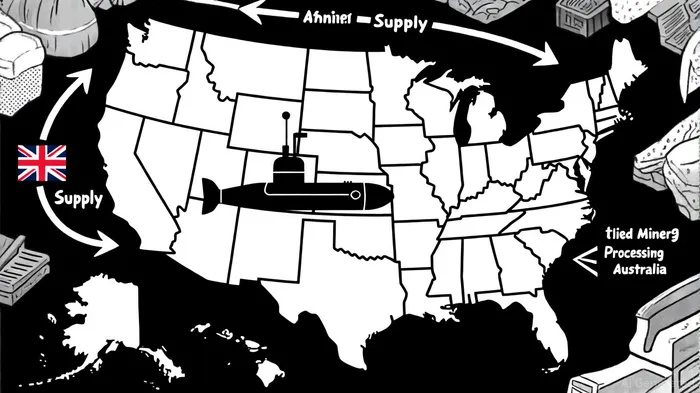

The strategy extends beyond domestic onshoring. The U.S. is leveraging "friend-shoring" alliances with Japan, Europe, and Australia to diversify supply chains. For instance, the UK and Australia have been designated as domestic sources under the Defense Production Act, enabling direct investments in allied mineral projects[6]. However, challenges remain: advanced processing facilities take 10–20 years to build, and geopolitical disruptions-such as trade wars or climate-related events-could destabilize supply[5]. A balanced approach combining domestic production, recycling, and international partnerships is critical to securing these materials[1].

High-Conviction Investment Targets

The intersection of submarine industrial revival and critical mineral security has created a pipeline of high-conviction investment opportunities:

- General Dynamics Electric Boat Corp.: As the prime contractor for Columbia-class submarines, its recent $986 million contract modification-funded in part by UK contributions-positions it to benefit from sustained SIB investments[1].

- Leonardo DRS: The $45 million SIB investment in its South Carolina facility directly ties to the Navy's need for domestic propulsion systems, with the expanded plant expected to open in 2026[3].

- MP Materials: The DoD's $550 million partnership with MP Materials ensures a secure supply of rare earths for defense applications, with price floors and offtake commitments reducing market volatility[1].

- Austal USA: Its Alabama Shipyard acquisition aligns with the Navy's push to expand submarine module production, supported by $3.9 billion in FY2025 SIB funding[4].

Legislative tailwinds further bolster these opportunities. The proposed SPEED and FoRGED Acts aim to streamline procurement and attract nontraditional defense contractors, including startups, to accelerate innovation[5].

The Strategic Imperative: Outpacing China Through Industrial Resilience

The U.S. is betting on its industrial base to outpace China in the Indo-Pacific. Submarine production and critical mineral security are linchpins of this strategy, with the AUKUS partnership and SIB25 study underscoring the need for sustained investment[1]. While challenges like workforce shortages and processing delays persist, the scale of government spending and public-private partnerships suggests a long-term commitment to reshaping the defense industrial landscape.

For investors, the message is clear: sectors directly tied to submarine modernization and critical mineral independence offer compelling growth potential. As the DoD's $3.9 billion SIB investment and MP Materials' rare earth partnership demonstrate, the U.S. is not merely reacting to China's rise-it is building a resilient industrial base to lead the next era of global security.

Comentarios

Aún no hay comentarios