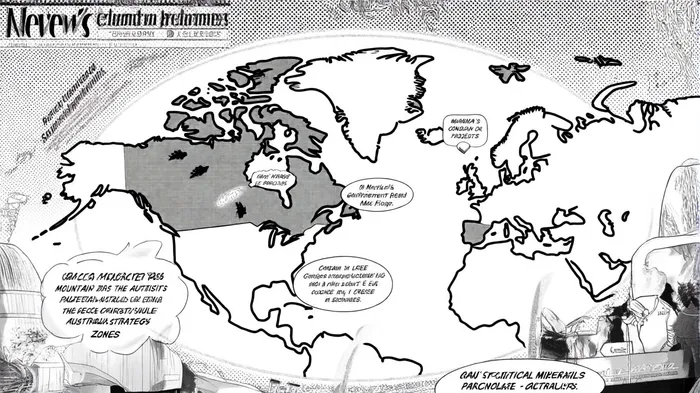

Strategic Mineral Asset Development in Geopolitically Stable Regions: A New Era for Rare Earth Element Supply Chain Resilience

The global race to secure rare earth element (REE) supply chains has intensified as nations grapple with the vulnerabilities exposed by China's dominance in the sector. For investors, the focus has shifted to geopolitically stable regions—such as Canada, Australia, and Europe—where governments and corporations are actively developing REE assets to counterbalance China's 60% share of global production[1]. This article examines the strategic initiatives in these regions, emphasizing how policy frameworks, corporate innovation, and technological advancements are reshaping supply chain resilience.

Canada: Reclaiming a Legacy in Rare Earths

Canada's Mountain Pass project, once a cornerstone of U.S. REE production, has reemerged as a focal point for North American supply chain diversification. While historical operations declined due to competitive pressures from China, recent investments in sustainable extraction technologies and partnerships with U.S. agencies signal a revival[2]. For instance, the U.S. Department of Energy's Critical Minerals and Materials Program has allocated funding to advance processing techniques at Mountain Pass, reducing reliance on Chinese refining infrastructure[2].

Government policies in Canada also prioritize environmental sustainability, with stringent regulations ensuring that REE extraction aligns with net-zero goals. This alignment is critical, as global demand for REEs—used in electric vehicles, wind turbines, and defense systems—is projected to grow 8% annually through 2030[3]. By integrating green technologies, Canadian projects position themselves as both geopolitically reliable and environmentally responsible.

Australia: Leveraging Light Rare Earths for Global Markets

Australia's vast deposits of light rare earth elements (LREEs)—notably neodymium and praseodymium—have drawn significant attention. These elements are essential for high-strength magnets in renewable energy and electric vehicle (EV) technologies. While the country's mining sector has historically focused on heavy rare earths, recent exploration efforts in Western Australia and Queensland are targeting LREE-rich deposits[2].

The Australian government has complemented these efforts with policies to streamline permitting and incentivize downstream processing. For example, the Critical Minerals Facilitation Office (CMFO) has fast-tracked projects that align with national security and climate objectives[2]. Corporate players, such as Lynas Rare Earths, have also partnered with international firms to develop closed-loop recycling systems, reducing waste and enhancing supply chain efficiency[2].

Europe: A Policy-Driven Push for Autonomy

The European Union's Critical Raw Materials Act, enacted in 2023, underscores its commitment to reducing dependency on non-EU suppliers for REEs. The act mandates a 10% domestic processing capacity for critical minerals by 2030, a target achievable through investments in exploration and recycling infrastructure[3]. Countries like Sweden and Finland are already advancing projects in their mineral-rich northern regions, supported by EU grants for green hydrogen-powered extraction technologies[3].

Corporate strategies in Europe emphasize vertical integration. For example, companies like Umicore and BASF have established partnerships to develop rare earth processing facilities within the EU, bypassing traditional bottlenecks in Chinese-dominated refining hubs[3]. These initiatives are bolstered by the EU's Carbon Border Adjustment Mechanism (CBAM), which penalizes carbon-intensive imports and incentivizes local, low-emission production[3].

Technological Innovations as a Catalyst

Across all three regions, technological advancements are redefining supply chain resilience. In Canada, isotope geochemistry techniques are improving ore body mapping, while Australia's use of AI-driven exploration tools is accelerating discovery timelines[2]. Europe's focus on recycling technologies—such as urban mining of electronic waste—further diversifies supply sources[3].

Investment Implications

For investors, the convergence of geopolitical stability, supportive policies, and technological innovation in Canada, Australia, and Europe presents a compelling opportunity. Unlike China's state-controlled model, these regions offer transparent governance and diversified supply chains, mitigating risks of export restrictions or geopolitical friction[2]. Moreover, their alignment with global decarbonization goals ensures long-term relevance in the clean energy transition.

However, challenges remain. High capital expenditures for processing infrastructure and the need for skilled labor in remote mining regions could delay timelines. Investors must also monitor regulatory shifts, such as the EU's CBAM, which could alter cost structures for imported materials[3].

Conclusion

The rare earth element supply chain is undergoing a strategic realignment, driven by the imperative for resilience in a multipolar world. Canada, Australia, and Europe are not merely diversifying supply—they are redefining it through policy foresight, corporate collaboration, and technological ingenuity. For investors, these regions represent a critical nexus of geopolitical stability and industrial innovation, offering a hedge against the volatility of China-centric supply chains.

Comentarios

Aún no hay comentarios