Strategic Diversification and Resilience in Autonomous Vehicle and EV Supply Chains: Navigating a Shifting Mobility Landscape

The global automotive industry is undergoing a seismic transformation as autonomous vehicle (AV) and electric vehicle (EV) technologies redefine supply chain dynamics. By 2025, EV sales are projected to exceed 20 million units annually, accounting for over a quarter of global car sales. This shift is not merely a technological revolution but a reconfiguration of value chains, with profound implications for suppliers, investors, and policymakers. While the transition to electrification and autonomy presents immense opportunities, it also exposes vulnerabilities in traditional supply chains, particularly for firms reliant on internal combustion engine (ICE) components.

Risks in the AV/EV Supply Chain

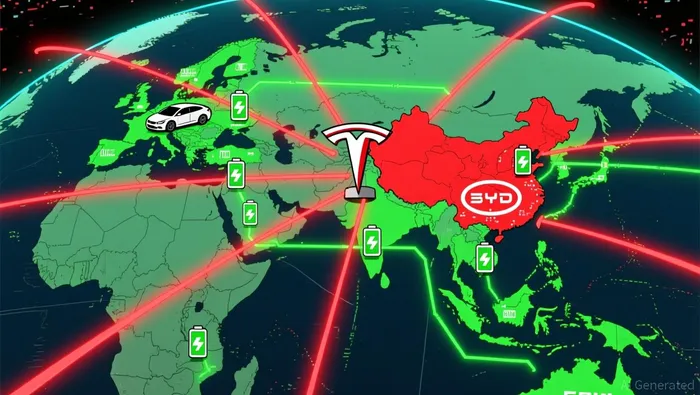

The electrification of transportation has disrupted long-standing supplier ecosystems. EVs require fewer mechanical parts than ICE vehicles-up to 70% fewer components in some cases-but demand advanced electronics, software, and battery systems. For suppliers specializing in exhaust systems, fuel pumps, or transmissions, this shift threatens obsolescence. Meanwhile, the lithium-ion battery, which constitutes up to 50% of an EV's value, has become a focal point of competition. Legacy automakers and suppliers now face pressure from vertically integrated EV manufacturers like TeslaTSLA-- and BYD, which control critical segments of the battery supply chain.

The electrification of transportation has disrupted long-standing supplier ecosystems. EVs require fewer mechanical parts than ICE vehicles-up to 70% fewer components in some cases-but demand advanced electronics, software, and battery systems. For suppliers specializing in exhaust systems, fuel pumps, or transmissions, this shift threatens obsolescence. Meanwhile, the lithium-ion battery, which constitutes up to 50% of an EV's value, has become a focal point of competition. Legacy automakers and suppliers now face pressure from vertically integrated EV manufacturers like TeslaTSLA-- and BYD, which control critical segments of the battery supply chain.

Geopolitical tensions further complicate the landscape. European nations, for instance, are recalibrating their dependencies on Chinese EV technology. The MERICS Europe-China Resilience Audit highlights how countries like the Czech Republic and France are implementing measures to counter Chinese influence, including bans on Chinese AI models in public administration and calls for EU-level procurement restrictions. Yet, these efforts are constrained by economic realities: one in four EVs sold in the EU in 2024 was produced in China, underscoring the region's reliance on Chinese manufacturing and components.

Opportunities in a Diversifying Landscape

Despite these risks, the AV/EV transition offers significant opportunities for innovation and strategic positioning. Emerging markets, in particular, are becoming critical battlegrounds. Chinese EV companies like BYD and Chery are establishing local production hubs in Brazil, Thailand, and Indonesia to bypass Western trade barriers and capitalize on price-sensitive markets. These investments are not limited to battery production but extend to upstream materials and downstream assembly, creating localized ecosystems that reduce transportation costs and regulatory friction.

In Europe, strategic diversification is gaining traction. Over 70% of EU firms operating in China have reviewed their supply chain strategies, with many relocating production closer to China or establishing alternative supply chains in Southeast Asia. The European Commission's Critical Raw Materials Act (CRM Act) aims to bolster domestic sourcing of lithium, cobalt, and rare earth minerals-key inputs for EV batteries. Meanwhile, regional initiatives like the EU-Mercosur Free Trade Agreement are being leveraged to strengthen supply chains in Southern and Eastern Europe, with Greece, Bulgaria, and Romania identified as potential beneficiaries.

Resilience Through Strategic Partnerships and Regionalization

The "cost of resilience" mindset is reshaping global supply chain strategies. Companies are moving away from single-source, cost-driven models toward distributed, regionalized networks that balance agility with financial sustainability. For example, the United States has imposed tariffs of up to 145% on Chinese EVs, prompting retaliatory measures and accelerating the search for alternative suppliers. Similarly, Chinese automakers are diversifying their investments beyond Europe, with 41% of post-2024 EV-related investments shifting to Asia and the Middle East and North Africa (MENA) region.

Collaborative innovation is another pillar of resilience. The European Union Chamber of Commerce in China notes that deflation in China and inflation in Europe have worsened trade imbalances, prompting firms to reevaluate sourcing strategies. This has led to increased partnerships between European and non-Chinese suppliers, particularly in battery recycling and second-life applications, which could reduce dependency on raw material imports.

Conclusion: Balancing Risk and Opportunity

The AV/EV supply chain is a high-stakes arena where strategic foresight determines success. For investors, the key lies in identifying firms that can navigate dual pressures: mitigating geopolitical and regulatory risks while capitalizing on the growth of electrification and autonomy. Suppliers that pivot from ICE components to software, battery management systems, or regionalized production hubs are likely to thrive. Conversely, those clinging to outdated models risk being outcompeted by agile, vertically integrated players.

As the industry evolves, resilience will hinge on diversification-not just of suppliers but of geographies, technologies, and partnerships. The winners in this new mobility landscape will be those who embrace complexity, innovate rapidly, and align with the shifting priorities of a decarbonizing world.

Comentarios

Aún no hay comentarios