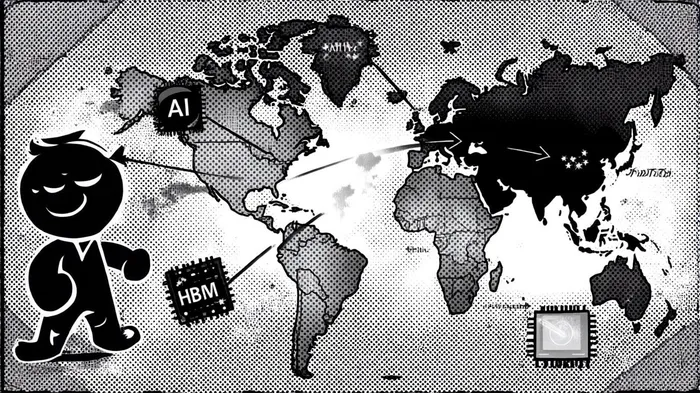

U.S. Semiconductor Export Controls Reshape Global Supply Chains and Spark Investment Shifts

The U.S. semiconductor export control regime has undergone a seismic transformation since 2020, evolving from targeted restrictions to a broad, strategic framework aimed at curbing China's access to advanced technologies. These policies, now spanning AI, quantum computing, and high-bandwidth memory (HBM), have not only reshaped global supply chains but also catalyzed a reallocation of capital toward alternative technology hubs in Southeast Asia, India, and the European Union. For investors, the interplay of regulatory tightening and geopolitical recalibration presents both risks and opportunities.

The Evolution of U.S. Export Controls: From Precision to Pervasive Restrictions

The Biden administration's December 2024 export control updates marked a pivotal escalation in the U.S. strategy to limit China's technological ascent. By imposing country-wide restrictions on HBM-a critical enabler of AI workloads-the policy directly targeted the backbone of China's AI ambitions, according to a CSIS analysis. This followed earlier milestones: the October 2022 rules that restricted advanced logic chips and manufacturing equipment, and the October 2023 revisions that expanded controls to include advanced packaging and DRAM, as detailed in a Congressional Research Service report. By 2025, the Foreign Direct Product Rule (FDPR) had been tightened to demand stricter due diligence from exporters, while the addition of 140 Chinese entities to the Entity List underscored the administration's resolve, as explained in a Mayer Brown advisory.

The cumulative effect has been a de facto bifurcation of the global semiconductor ecosystem. U.S. allies, including Japan and the EU, have aligned with these controls, creating a "clean" supply chain cluster focused on advanced-node technologies. Meanwhile, China's domestic players, such as SMIC and Huawei, are racing to fill gaps with 7nm and 180nm processes, though their output remains constrained by U.S.-allied equipment bans, according to a ResearchGate study.

Supply Chain Disruptions and the Cost of Compliance

The tightening of export controls has exacted a tangible toll on U.S. semiconductor firms. According to an RS Web Solutions report, NvidiaNVDA-- and AMDAMD-- faced revenue losses of $5.5 billion and $800 million, respectively, in 2025 due to restricted access to Chinese markets. These losses highlight the double-edged nature of export controls: while they aim to protect national security, they also erode the profitability of U.S. firms reliant on China's vast demand.

For global supply chains, the impact has been equally profound. China's push for self-reliance has accelerated, with firms like Yangtze Memory Technologies Co. (YMTC) aiming for 15% of the global NAND market by 2026. However, U.S. restrictions on EUV lithography tools and HBM have constrained China's ability to scale advanced AI chips, limiting Huawei's production to 200,000 units in 2025, according to that RS Web Solutions report. This has created a vacuum in mid-tier semiconductor demand, which is being filled by alternative hubs.

Investment Opportunities in Alternative Tech Hubs

As the U.S.-China tech rivalry intensifies, capital is flowing into regions positioned to benefit from supply chain diversification. Three key areas stand out:

1. The European Union: A Strategic Counterbalance

The EU's Chips Act, allocating €3.3 billion to bolster domestic semiconductor manufacturing, has positioned the bloc as a critical player. TSMC's expansion in Arizona and Samsung's $17 billion Texas fabrication plant underscore the region's appeal, while European firms are gaining traction in advanced packaging and materials, according to a CFR blog post. Investors should monitor EU subsidies for R&D in quantum computing and AI, which align with U.S. export control priorities.

2. Southeast Asia: The New Manufacturing Frontier

Vietnam and Malaysia are emerging as cost-effective alternatives to China, leveraging lower labor costs and government incentives. For instance, TSMCTSM-- and IntelINTC-- have expanded foundry operations in Vietnam, while Malaysia's focus on advanced packaging has attracted firms like ASMLASML--, as described in a Management Curated piece. However, risks remain: geopolitical tensions in the South China Sea and reliance on U.S.-allied equipment could disrupt long-term growth.

3. India: A Long-Term Bet on Domestic Production

India's $18 billion semiconductor investment plan, including a $9.1 billion Production Linked Incentive (PLI) scheme, is laying the groundwork for commercial chip production by 2025. Gujarat's Tata-Powerchip joint venture and Micron's $22.5 billion Sanand facility highlight the scale of ambition. Yet, India's reliance on 180nm processes and foreign equipment means it will take years to compete with 3nm leaders like TSMC, as reported by TechWire Asia. For patient capital, India's ecosystem offers exposure to a $1.5 trillion domestic tech market.

Navigating the New Semiconductor Landscape

For investors, the key lies in balancing short-term volatility with long-term strategic shifts. U.S. export controls will likely continue to tighten, particularly as China advances in AI and quantum computing. However, the rise of alternative hubs offers diversification opportunities.

- Short-Term Focus: Prioritize firms supplying equipment and materials to EU and Southeast Asian manufacturers. ASML's EUV tools and Lam Research's deposition systems are critical enablers for advanced-node production.

- Long-Term Focus: Allocate capital to India's PLI-driven ecosystem and EU quantum/AI initiatives. These sectors align with global trends in AI democratization and energy-efficient computing.

The U.S. semiconductor export control regime is no longer just a policy tool-it is a catalyst for a new era of geographically diversified innovation. As supply chains fragment and new hubs emerge, investors who align with this evolution will be best positioned to capitalize on the next phase of the global tech race.

Comentarios

Aún no hay comentarios