Renault's Strategic Shift in Electric Mobility: Assessing the Long-Term Competitive Advantage of Its Ampere Motor Unit Production Line

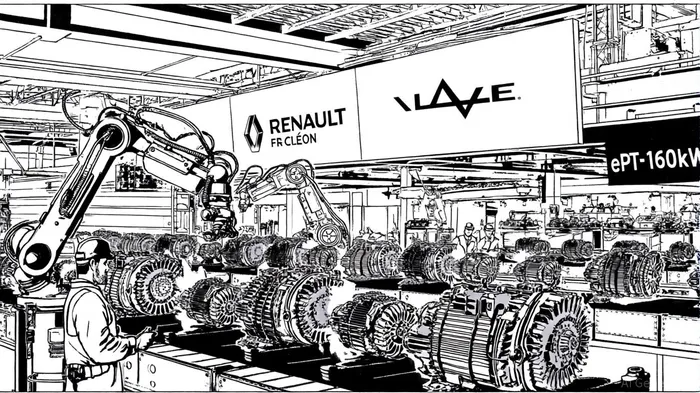

Renault Group's strategic pivot toward electric mobility has taken a decisive turn with the launch of its dedicated EV subsidiary, Ampère. At the heart of this transformation lies the Cléon plant in France, a $664 million investment since 2018 that now produces over one million electrified motors annually, including 500,000 for battery electric vehicles (BEVs) and 510,000 for hybrids [4]. This production line, coupled with Ampère's broader industrial and technological initiatives, positions Renault to challenge established EV leaders while navigating the cost pressures of a maturing market.

Technical Innovation: Rare-Earth-Free Motors and Dual-Drive Systems

Renault's ePT-160kW motor, produced at Cléon, exemplifies the company's focus on sustainable and cost-effective engineering. This synchronous wound-rotor motor avoids rare earth materials—a critical advantage in a supply chain plagued by geopolitical risks and environmental concerns [5]. By eliminating reliance on rare earths, Renault reduces both production costs and carbon footprints, aligning with European Union decarbonization targets.

For performance-oriented segments, the Cléon plant also produces the 7DL twin motor, a 250 kW dual-unit system powering each wheel independently in the Alpine A390. This torque-vectoring system enables 0–100 km/h acceleration in 3.9 seconds, showcasing Ampère's ability to cater to both mass-market affordability and premium performance [1]. Such versatility strengthens Renault's product portfolio, addressing diverse consumer demands without sacrificing efficiency.

Production Capacity and Industrial Flexibility

The Cléon plant's capacity to scale to one million motors annually by 2024, combined with the Douai plant's modular AmpR Small and AmpR Medium platforms, underscores Renault's industrial agility. The Douai facility, part of the ElectriCity cluster, already produces six electric models for four brands (Renault, Alpine, Nissan, and Mitsubishi) and is projected to deliver 89,000 units in 2024 [4]. This cross-brand flexibility reduces capital intensity and accelerates time-to-market for new models, a critical edge in a sector defined by rapid innovation cycles.

Moreover, Renault's E-Mobility Academy at Cléon ensures a skilled workforce capable of adapting to evolving technologies, mitigating labor bottlenecks during its transition to full electrification [5]. Such investments in human capital are often overlooked but are essential for sustaining long-term competitiveness.

Battery Strategy: Cost Reduction and Supply Chain Resilience

Ampère's battery strategy is equally transformative. By integrating Lithium Iron Phosphate (LFP) chemistry—a less energy-intensive and cheaper alternative to Nickel Cobalt Manganese (NCM)—Renault aims to reduce EV costs by 40% by 2027 [1]. Collaborations with LG Energy Solution and CATL to establish a European LFP supply chain ensure raw material security, while Cell-to-Pack (CTP) technology—a world premiere for pouch-type batteries—promises a 20% cost reduction starting in 2026 [3]. These advancements position Ampère to compete directly with Chinese EV manufacturers, who have historically dominated the affordability segment.

Software-Defined Vehicles and Future-Proofing

Beyond hardware, Ampère is developing a software-defined vehicle (SDV) platform, slated for 2026. This centralized architecture with cloud connectivity enables perpetual software updates, enhancing residual values and customer retention—a critical differentiator in an era where software defines user experience [3]. By embedding over-the-air upgrade capabilities, Renault addresses a key pain point for EV buyers: the risk of obsolescence.

Financial Targets and Market Positioning

Ampère's financial ambitions are ambitious but achievable. The unit aims to reach €10 billion in revenues by 2025, sell 300,000 vehicles annually by 2025, and achieve a 10% operating margin [2]. A planned 2024 IPO, targeting a €8–10 billion valuation, will further de-risk Renault's transformation by securing independent capital and boosting investor confidence [2]. These metrics, combined with a goal to increase European EV market share from 10% to 14%, suggest a clear path to profitability.

Conclusion: A Blueprint for Sustainable Leadership

Renault's Ampère unit is not merely a response to regulatory pressures but a calculated bid to dominate the next decade of mobility. By combining rare-earth-free motors, flexible production platforms, cost-competitive LFP batteries, and forward-looking software, Ampère addresses the core challenges of scalability, affordability, and innovation. While risks such as supply chain disruptions and intense competition from Asian rivals persist, Renault's vertically integrated strategy—bolstered by alliances with Google, Qualcomm, and Valeo—provides a robust foundation for long-term success. For investors, Ampère represents a compelling case study in how traditional automakers can reinvent themselves to thrive in the electric age.

Comentarios

Aún no hay comentarios