Reassessing U.S. AI and Semiconductor Investments in Light of Supply Chain Vulnerabilities

The U.S. semiconductor and AI infrastructure landscape in 2025 is defined by a paradox: unprecedented demand for advanced chips coexists with systemic vulnerabilities in supply chains and geopolitical tensions. As artificial intelligence (AI) systems grow more complex, the race to secure access to cutting-edge semiconductors has become a linchpin of national and economic security. Yet, the U.S. remains heavily exposed to risks ranging from overreliance on foreign manufacturing to the rapid advancement of Chinese competitors. For investors, this environment demands a recalibration of strategies to account for both operational fragility and strategic competition.

Geopolitical Risks: A Fragile Foundation

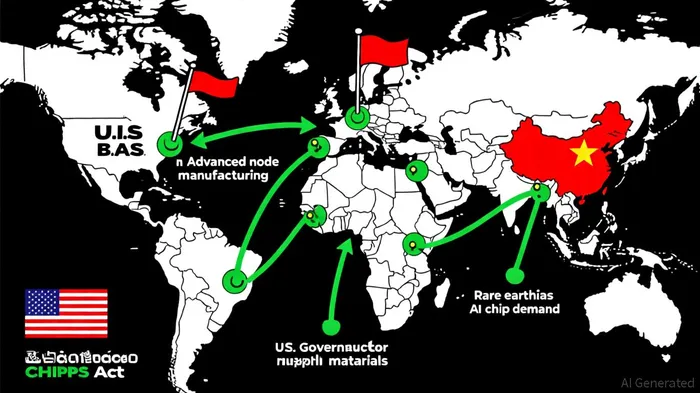

The U.S. semiconductor supply chain is underpinned by a critical dependency on Taiwan Semiconductor Manufacturing Company (TSMC), which produces over 90% of the world's most advanced logic chips [4]. This concentration creates a single point of failure, as any disruption—whether from geopolitical conflict, cyberattacks, or natural disasters—could paralyze global AI infrastructure and defense systems. The Biden administration's export controls, introduced in 2022 and tightened in 2023, aim to curb China's access to advanced manufacturing equipment and chips. However, these measures have had mixed success. For instance, a September 2024 breach allowed Huawei to procure millions of advanced AI chip dies through a Chinese proxy company, undermining U.S. restrictions [2].

Meanwhile, China's aggressive investments in domestic semiconductor production, under initiatives like “Made in China 2025,” are narrowing the gap with U.S. leadership. Chinese firms like SMIC and Huawei have developed competitive alternatives, such as the Ascend 910B and 910C chips, while advancing 7nm manufacturing capabilities [4]. China's control over rare earth elements—critical for chip production—also provides leverage in potential retaliatory measures against U.S. export controls [3]. These dynamics suggest that U.S. dominance in AI semiconductors is no longer guaranteed, and investors must factor in the likelihood of prolonged technological and geopolitical rivalry.

Operational Risks: Bottlenecks and Resilience Gaps

Beyond geopolitical tensions, operational challenges in semiconductor manufacturing are intensifying. The surging demand for AI-specific chips—such as GPUs, TPUs, and AI accelerators—has strained wafer production capacity, with AI servers now accounting for a third of semiconductor die area in high-performance systems [3]. This demand is driven by the rapid adoption of generative AI, with 78% of global businesses integrating AI into at least one function and 88% of C-suite executives accelerating AI deployment [1].

Despite advancements in AI-driven design and manufacturing tools—such as Cadence Cerebrus and Synopsys DSO.ai—industry-wide bottlenecks persist. TSMC's 3nm production lines, for example, faced a 20% yield improvement after adopting AI-driven defect detection, but material innovation and energy efficiency remain unresolved challenges [4]. Additionally, the U.S. faces a projected 35% gap between the supply and demand of semiconductor design workers by 2030 [1], compounding delays in scaling production.

The CHIPS and Science Act, while a step toward reshoring production, has yet to address systemic issues like high capital costs and supply chain dependencies on specialized equipment (e.g., ASML's extreme ultraviolet lithography machines) [4]. For now, the U.S. remains reliant on foreign suppliers for over 90% of advanced semiconductor production [4], creating a fragile foundation for AI infrastructure.

Strategic Responses and Investment Implications

To mitigate these risks, the U.S. government has prioritized initiatives like the Securing Semiconductor Supply Chains Act of 2025, which coordinates with state-level economic development organizations to attract foreign direct investment in fabrication, advanced packaging, and material production [2]. The Department of Defense's Trusted Supplier Program, meanwhile, accredits foundries to support defense-grade chips, emphasizing the need for “trusted chips” in AI infrastructure [1]. However, experts caution that the term “trusted chips” risks oversimplifying the nuanced policy goals of supply chain resilience and export control [1].

For investors, the key lies in balancing exposure to U.S.-led initiatives with hedging against geopolitical and operational risks. This includes:

1. Diversifying supply chain dependencies: Supporting companies investing in alternative production regions (e.g., Europe, Southeast Asia) or adopting modular design approaches to reduce reliance on single-node manufacturing.

2. Prioritizing resilience over speed: Allocating capital to firms developing AI-driven tools for yield optimization, dynamic demand forecasting, and supply chain risk mitigation [4].

3. Monitoring geopolitical shifts: Closely tracking U.S.-China trade dynamics, TSMC's compliance with U.S. regulations, and China's progress in self-sufficiency, which could reshape global chip pricing and availability [2].

Conclusion

The U.S. AI and semiconductor sectors stand at a crossroads. While government policies and technological innovation offer pathways to resilience, the interplay of geopolitical tensions and operational bottlenecks demands a cautious, strategic approach to investment. Investors must navigate this landscape by prioritizing adaptability, diversification, and a deep understanding of the evolving risks in AI infrastructure development. As the race for semiconductor dominance intensifies, the ability to anticipate and respond to disruptions will define long-term success.

Comentarios

Aún no hay comentarios