Post-Tariff Inflationary Risks: Structural Cost Pressures Reshape Global Supply Chains and Goods Pricing

The imposition of sweeping tariffs in 2025 has triggered a seismic shift in global supply chains, creating structural cost pressures that are now translating into persistent inflationary risks across key economies. As businesses grapple with the fallout from these trade policies, the interplay between reshoring, automation, and supply chain diversification is reshaping the economic landscape. For investors, understanding these dynamics is critical to navigating the evolving risks and opportunities in goods pricing.

Structural Cost Pressures: Reshoring, Automation, and Diversification

The 2025 tariffs, which include rates as high as 46% on Vietnamese goods and 25% on Chinese semiconductors and electric vehicle batteries, according to a Taylor & Francis special issue, have forced companies to reconfigure their sourcing strategies. Reshoring operations to the U.S. or nearshoring to Mexico and India has become a priority for many firms. However, these adjustments come at a steep cost. According to a 2025 industry survey, nearly two-thirds of companies estimate that reshoring would double or more than double their current supply chain costs, with 57% citing cost concerns as the primary barrier. Labor shortages further exacerbate these challenges, as U.S. labor costs are 4–6 times higher than in Vietnam, and 78% of manufacturers report skilled worker shortages.

Automation, while a long-term solution, requires significant upfront investment. For instance, the automotive sector faces a 8–12% increase in production costs due to tariffs on Mexican auto parts, translating to $2,500–$4,000 per vehicle. To mitigate these pressures, firms are adopting pricing adjustment clauses in contracts and diversifying suppliers. Yet, even these strategies are imperfect. A Discovery Alert analysis suggests a hybrid approach-reshoring strategic operations while nearshoring labor-intensive production-is emerging as a compromise, but it introduces operational complexity and higher margins of error.

Inflationary Pressures: From Supply Chains to Consumer Prices

The structural cost shocks from tariff-driven supply chain reconfigurations are now manifesting in broader inflationary trends. By August 2025, the U.S. Consumer Price Index (CPI) had risen 2.9% year-over-year, with core inflation projected to reach 3.2% by year-end, according to an OECD interim report. The OECD attributes this to a record-high effective U.S. tariff rate of 19.5%, the highest since 1933. For context, a 25% tariff on Chinese imports alone could add 0.7–1.2 percentage points to U.S. core inflation.

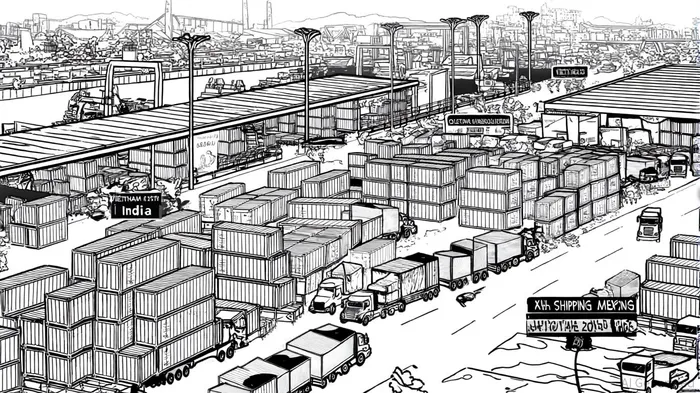

Industries reliant on globalized production, such as electronics and apparel, face direct price hikes. Companies anticipate 5–7% increases in consumer electronics and apparel due to tariff-driven cost escalations. Meanwhile, sectors like agriculture are indirectly affected: China's 15% soybean tariff has pushed U.S. soybean prices to $10.50 per bushel, threatening 300,000 Midwest farms. These pressures are compounded by logistical bottlenecks, such as a 22% volume spike at U.S. West Coast ports and a 14-day extension in shipping times via Africa's Cape of Good Hope.

Macroeconomic Implications and Investment Considerations

The inflationary ripple effects of 2025 tariffs are reshaping growth trajectories. U.S. GDP growth is projected to slow from 2.8% in 2024 to 1.5% in 2026, as tariff costs and reduced immigration offset AI-driven productivity gains. The euro area and China face similar headwinds, with growth forecasts revised downward to 1.0% and 4.4%, respectively. For investors, these trends highlight the need to prioritize sectors with pricing power and supply chain agility.

Companies in labor-intensive industries, such as textiles and fresh produce, may struggle to absorb costs, making them vulnerable to margin compression. Conversely, firms investing in automation and regionalization-such as Tesla's expanded operations in Mexico or Apple's 18% Vietnam sourcing increase-may gain resilience. Additionally, logistics providers and port operators stand to benefit from increased demand for nearshoring and regional trade routes.

Conclusion

The 2025 tariff regime has created a new era of structural cost pressures in global supply chains, with inflationary risks embedded in reshoring, automation, and diversification strategies. For investors, the key lies in identifying firms capable of navigating these challenges through innovation and strategic flexibility. As central banks face the delicate task of balancing inflation control with economic growth, the long-term winners will be those that adapt to a fragmented, higher-cost global trade environment.

Comentarios

Aún no hay comentarios