Post-Pandemic Supply Chain Resilience: Strategic Diversification as a Catalyst for Investment Returns

The post-pandemic era has fundamentally reshaped global supply chains, exposing vulnerabilities that once seemed unthinkable. As businesses grapple with geopolitical tensions, trade wars, and climate-related disruptions, strategic diversification has emerged as a cornerstone of resilience. This shift is not merely a reactive measure but a calculated investment in long-term stability, with tangible financial and operational benefits.

The Rise of Diversification: From Risk Mitigation to Competitive Advantage

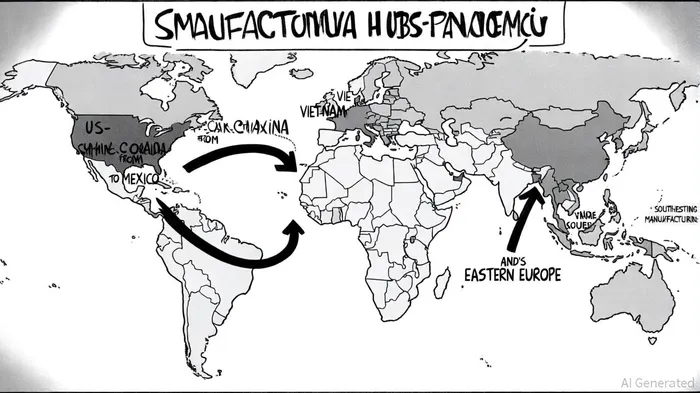

According to a report by Deloitte, 93% of businesses reported supply chain disruptions during the pandemic, with diversified firms experiencing a 30% reduction in delays compared to those reliant on single-source suppliers [3]. This statistic underscores the growing emphasis on supplier diversification, nearshoring, and reshoring. For instance, the U.S. trade share with China fell from 21.2% in 2018 to 13.9% in 2023, while Mexico became a dominant partner under the USMCA trade agreement [2]. Such shifts reflect a strategic pivot toward regionalizing supply chains to mitigate risks from tariffs and geopolitical instability.

Nearshoring, in particular, has gained momentum. A 2025 analysis by Frost & Sullivan notes that Mexico's infrastructure investments, including a new railroad to rival the Panama Canal, have made it a preferred hub for U.S. manufacturers [1]. Similarly, Eastern Europe's Poland and the Mediterranean's Morocco have leveraged geographic proximity and infrastructure to attract global buyers, with inspection demand in these regions surging by over 50% year-over-year [4].

Digital Transformation: The Invisible Backbone of Resilience

Beyond physical relocation, digital tools are redefining supply chain agility. AI and analytics have improved demand forecasting by 35%, enabling companies to anticipate disruptions and optimize inventory [3]. For example, Intel's adoption of AI-driven logistics reduced its Atom chip production cycle from nine weeks to two, cutting costs by over $4 per unit [1]. Meanwhile, SAP's cloud-based solutions have allowed firms like Nestlé to achieve real-time visibility across global operations, enhancing responsiveness to market shifts [5].

Case Studies: Quantifiable Gains from Diversification

Several companies have demonstrated the financial rewards of strategic diversification:

- Deere & Company redesigned its supply chain network, achieving a $1 billion inventory reduction and 5% annual transportation savings through optimized cross-dock locations [1].

- Starbucks restructured its supply chain into three operational groups (“plan,” “make,” “deliver”), saving $500 million between 2009 and 2010 by streamlining logistics partnerships [1].

- Intel's nearshoring investments in Costa Rica and Vietnam have diversified its production base, reducing exposure to geopolitical risks while aligning with sustainability goals [5].

Financial Metrics and ROI: The Investor's Lens

Investors seeking to capitalize on this trend should focus on key performance indicators (KPIs) such as inventory turnover, freight cost per unit, and on-time delivery rates [1]. For instance, Deere's inventory turnover improved by 15% post-redesign, directly correlating with its $1 billion savings. Similarly, Intel's procurement ROI increased by 8% after implementing AI-driven supplier analytics [1]. These metrics not only reflect operational efficiency but also signal a company's ability to adapt to disruptions—a critical factor in today's volatile markets.

Future Outlook: Balancing Cost, Resilience, and Sustainability

As supply chains evolve, the integration of circularity and AI readiness will define the next phase of resilience. A 2025 report by Global Trade Magazine highlights that 78% of supply chain leaders prioritize circularity to reduce waste and enhance resource efficiency [1]. Meanwhile, automation and robotics are making nearshoring more viable, particularly in Mexico, where labor costs are offset by proximity to U.S. markets [2].

However, challenges remain. Tariff uncertainties and renegotiations of agreements like the USMCA by 2026 could complicate long-term planning [1]. Investors must weigh these risks against the growing demand for resilient supply chains, which are projected to grow at a 12% CAGR through 2030 [5].

Conclusion: A Resilient Supply Chain as a Strategic Asset

The post-pandemic landscape has proven that supply chain resilience is no longer optional—it is a competitive imperative. Companies that have embraced diversification, digital tools, and regionalization are not only surviving but thriving, with measurable gains in profitability and operational agility. For investors, the lesson is clear: portfolios that prioritize supply chain resilience will outperform in an era of persistent uncertainty.

Comentarios

Aún no hay comentarios