PepsiCo's Strategic Cost Management Amid Persistent Supply Chain Challenges: Operational Resilience and Margin Protection in Focus

PepsiCo's Strategic Cost Management Amid Persistent Supply Chain Challenges: Operational Resilience and Margin Protection in Focus

In an era of volatile global trade dynamics and shifting consumer preferences, PepsiCoPEP-- has emerged as a case study in strategic cost management. The company's ability to balance operational resilience with margin protection has become critical to its long-term competitiveness. Recent developments-from advanced supply chain digitization to aggressive productivity initiatives-underscore PepsiCo's commitment to navigating persistent challenges while safeguarding profitability.

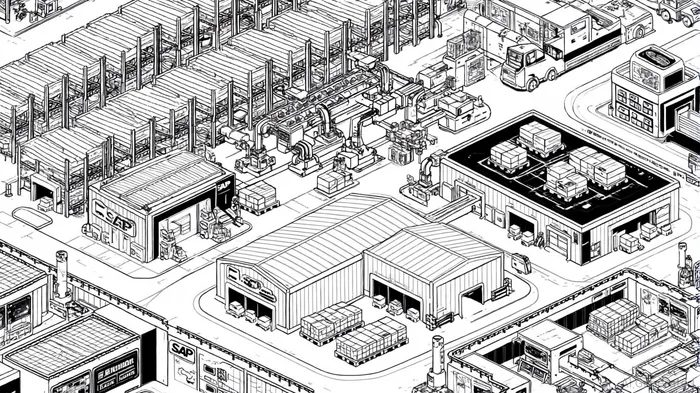

Supply Chain Digitization: A Foundation for Resilience

PepsiCo's partnership with SAP to implement integrated systems like S/4HANA and Integrated Business Planning (IBP) has been a cornerstone of its supply chain modernization, according to Inside PepsiCo's Supply Chain Transformation. By unifying fragmented planning systems across its business units, the company has achieved a 15% improvement in forecast accuracy and a 20% reduction in working capital requirements, enabling real-time visibility into inventory, production, and logistics and allowing PepsiCo to pivot swiftly in response to disruptions such as geopolitical tensions or regional demand shifts.

The company's emphasis on diversifying supply chain hubs further strengthens its resilience. For instance, expanding manufacturing footprints in Southeast Asia and Latin America has mitigated risks tied to over-reliance on single regions. This strategy aligns with PepsiCo's Operations Management, 10 Critical Decisions, which prioritize process optimization and cost minimization.

Financial Performance: Navigating Regional Disparities

PepsiCo reported adjusted earnings per share (EPS) of $2.29 and revenue of $23.94 billion, exceeding expectations, according to PepsiCo Q3 2025 results. International markets, particularly India and Southeast Asia, drove growth through localized product innovations like spicy snacks and region-specific beverage flavors. However, North America faced a volume decline, attributed to inflation, health-conscious consumer trends, and brand fatigue.

Despite these headwinds, PepsiCo's diversified portfolio cushioned the blow. Strong performance in beverage and snack categories offset weaker foodservice demand, demonstrating the value of a balanced product mix. Yet, the company's full-year profit outlook was revised downward in early 2025, according to Morningstar, as escalating tariffs and supply chain costs pressured margins.

Challenges: Tariffs, Impairments, and Strategic Reassessment

The impact of global trade tensions has been profound. Tariffs have inflated supply chain costs, forcing PepsiCo to absorb margin pressures that led to a rare quarterly earnings miss in early 2025. Notably, historical data shows that after earnings misses, PEP's stock has seen a statistically significant negative average return of approximately -1.1% after 29–30 days, with a win rate of 45–50% in the first month. Compounding these issues, the company recorded a $1.86 billion impairment charge in Q2 2025 for underperforming brands like Rockstar and Be & Cheery, as noted in PepsiCo Earnings Q3 2025. These impairments signal a reevaluation of past acquisitions and a shift toward higher-impact investments, a move also discussed in coverage about PepsiCo to streamline operations.

Productivity Initiatives: Automation and Streamlining

To counter these challenges, PepsiCo has accelerated its multi-year productivity plan. The company is investing heavily in automation across manufacturing, warehousing, and distribution, aiming to reduce labor and operational costs, as detailed in PepsiCo's (PEP) Productivity & Cost-Saving Initiatives. By mid-2025, PepsiCo had closed underperforming plants, reduced its workforce by 5%, and renegotiated supplier contracts to cut procurement expenses, measures that industry coverage expects will support improved margins. These initiatives are projected to deliver a substantial increase in productivity savings in the second half of 2025.

The strategy extends beyond cost-cutting. PepsiCo is re-engineering its go-to-market systems to simplify processes and synchronize demand with supply. For example, AI-driven analytics now optimize inventory levels, reducing waste and overstocking in high-turnover markets. Additional reporting on the company's streamlining efforts outlines steps to synchronize procurement and production planning to capture cost savings more quickly.

Conclusion: A Model for Sustained Competitiveness

PepsiCo's approach to cost management reflects a dual focus on technological innovation and operational agility. While tariffs and impairments have created near-term headwinds, the company's investments in automation, supply chain diversification, and process optimization position it to protect margins and drive long-term growth. Investors should monitor key metrics such as working capital efficiency, regional revenue mix, and the success of its productivity initiatives in 2026.

Comentarios

Aún no hay comentarios