Nevada's Growing Role in Advanced Battery Manufacturing: Strategic Workforce Development and Industrial Scalability

Nevada is rapidly emerging as a linchpin in the U.S. advanced battery manufacturing sector, driven by strategic investments in workforce development and industrial scalability. As the global demand for lithium-ion batteries surges-driven by electric vehicles (EVs), renewable energy storage, and grid modernization-Nevada's unique confluence of natural resources, policy support, and private-sector innovation is positioning it as a critical hub. The state's "Lithium Loop" initiative, which aims to create a self-sustaining domestic supply chain from extraction to recycling, is underpinned by targeted workforce programs and partnerships that are reshaping the industrial landscape.

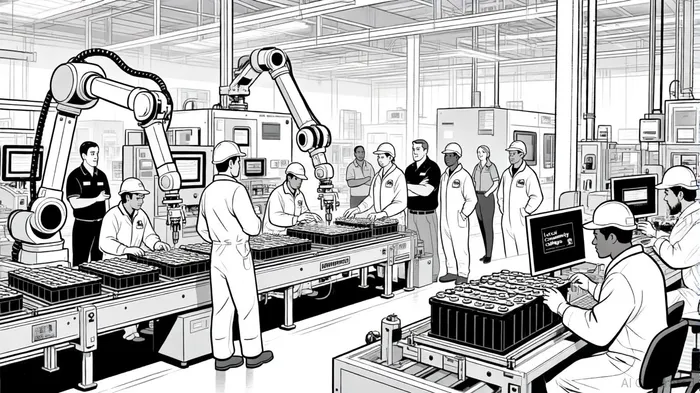

Workforce Development: Building a Skilled Talent Pipeline

Dragonfly Energy, a key player in the state's battery ecosystem, has been awarded $300,000 in funding from the Nevada Tech Hub to modernize its lithium battery manufacturing operations and expand training programs. This investment will upgrade production systems, advance toward ISO 9001 certification, and generate six-figure annual savings, a portion of which will be reinvested into workforce development. Collaborations with institutions like Truckee Meadows Community College and the University of Nevada, Reno, are creating tailored training pathways in machining, automation, and maintenance, directly addressing industry needs.

The Nevada Tech Hub, supported by a $21 million grant from the U.S. Economic Development Administration, is scaling this approach. Its five-year plan aims to train and upskill 50,000 workers, with a focus on underserved communities, including English language learners and individuals in the correctional system. The Nevada Native Nations Center, a first-of-its-kind initiative under the Tech Hub, is also forging career pathways through Recharge Nevada for Native American and Indigenous communities, ensuring inclusive growth. These programs are not just about filling jobs-they're about building a resilient, adaptable workforce capable of supporting the evolving demands of battery manufacturing.

Industrial Scalability: From Gigafactories to a Circular Economy

Nevada's industrial scalability is being propelled by ambitious projects from both established and emerging players. Dragonfly Energy's South Reno facility, spanning nearly 400,000 square feet, is a case in point. The company's ISO 9001 certification and automation upgrades are expected to significantly boost output while reducing costs, enabling it to scale operations and anchor high-value clean energy jobs.

Meanwhile, Lyten is pushing the envelope with plans to build the world's first lithium-sulfur battery gigafactory near Reno, targeting 10 GWh of annual production by 2025. This facility, which will create over 1,000 jobs, leverages lighter, higher-energy-density battery chemistry and domestically sourced materials, aligning with Nevada's circular economy goals, as noted by the Nevada Battery Coalition. Similarly, Octillion Power Systems is ramping up production at its Reno facility, aiming to produce 1 GWh of EV batteries by 2025 to support electric trucks, buses, and energy storage applications.

These projects are part of a broader coalition led by Recharge Nevada, which unites stakeholders across the battery lifecycle-including Tesla, Idaho National Lab, and local universities-to foster innovation and collaboration. By integrating extraction, processing, manufacturing, and recycling, Nevada is not just scaling production but also reducing reliance on global supply chains, a critical advantage in an era of geopolitical uncertainty.

Economic Impact and Investment Potential

The implications for investors are clear. Nevada's strategic investments in workforce development and industrial infrastructure are creating a virtuous cycle: skilled labor attracts capital, which in turn fuels further innovation and scalability. The state's focus on inclusivity-through programs targeting marginalized communities-also mitigates labor shortages and ensures long-term workforce stability, supported by Nevada Tech Hub programs at the University Center for Economic Development.

Moreover, the "Lithium Loop" model reduces environmental and economic risks by closing the battery lifecycle. For example, Kalkine Media details Dragonfly Energy's reinvestment of savings into training programs, ensuring that cost efficiencies are reinjected into the local economy, fostering a self-reinforcing ecosystem. This approach aligns with global sustainability trends, making Nevada an attractive destination for ESG-focused capital.

Conclusion

Nevada's ascent in advanced battery manufacturing is no accident-it's the result of deliberate, multi-pronged investments in people and infrastructure. By prioritizing workforce development and industrial scalability, the state is not only securing its role in the clean energy transition but also creating a blueprint for sustainable, inclusive economic growth. For investors, Nevada represents a rare intersection of policy tailwinds, technological innovation, and strategic foresight-a compelling case for long-term value creation.

Comentarios

Aún no hay comentarios