U.S. Legislative Pressure on China's Rare Earths Dominance and Aviation Supply Chains

The United States has intensified legislative and industrial efforts since 2023 to counter China's dominance in rare earth elements (REEs) and secure critical aviation supply chains, driven by strategic geopolitical risks and sector-specific vulnerabilities. These actions, including the Critical Minerals Security Act, National Defense Authorization Act (NDAA), and Inflation Reduction Act (IRA), aim to reduce dependency on China, which controls 99% of global heavy rare earth processing and 80% of critical mineral refining. However, the U.S. remains unprepared to fully replace China's role in the short term, exposing defense and aerospace sectors to supply chain disruptions.

Strategic Geopolitical Risks and Legislative Responses

China's recent export restrictions on seven rare earth elements and magnets have underscored the fragility of U.S. supply chains. These materials are indispensable for advanced military technologies, including F-35 fighter jets (900+ pounds of REEs) and Arleigh Burke-class destroyers (5,200+ pounds of REEs). To mitigate this risk, the Biden administration has banned Chinese-origin rare earth magnets in defense systems by 2027 and invoked the Defense Production Act to accelerate domestic production.

The Critical Minerals Security Act of 2025 mandates a comprehensive assessment of global REE resources and promotes collaboration with allies to develop clean mining and recycling technologies. Meanwhile, the NDAA for fiscal years 2023–2024 requires defense contractors to disclose mineral sourcing and diversify supply chains. These measures are complemented by the IRA, which offers tax credits for domestic rare earth processing, including $20 per kilogram for magnets produced in the U.S. and $30 per kilogram if 90% of materials are sourced domestically.

Sector-Specific Implications: Defense and Aerospace

The defense sector faces acute risks due to its reliance on REEs for high-performance systems. For instance, China's 2023 export controls on gallium and germanium—critical for semiconductor manufacturing—highlighted vulnerabilities in U.S. supply chains. The Department of Defense (DOD) aims to eliminate Chinese rare earths from weapon systems by 2027, but current stockpiles last only months, not years.

Aerospace manufacturing, meanwhile, grapples with workforce and material shortages as post-pandemic demand rebounds. Executive Order 13873 has targeted risks in unmanned aircraft systems (UAS) supply chains, particularly those involving Chinese adversaries. These challenges, while not directly tied to China, underscore the need for legislative interventions to strengthen domestic production.

Investment Trends and Industrial Responses

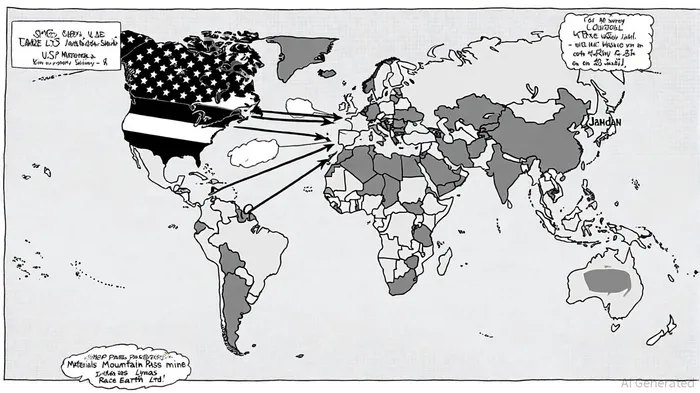

Legislative incentives have spurred investment in domestic rare earth projects. MP Materials, a key player, is expanding its Mountain Pass mine in California and building a rare earth refinement facility to reduce reliance on China. The company also plans a magnetics factory in Texas, supported by a $10 million DOD grant.

International collaborations are diversifying supply chains. The U.S. has partnered with Australia (Lynas Rare Earth Ltd.'s Texas processing plant) and Ukraine (a 50/50 mineral development partnership) to access critical resources. Emerging technologies like DARPA's EMBER initiative are exploring biomining to enhance domestic production.

Challenges and Opportunities

Despite progress, challenges persist. China's near-monopoly on heavy rare earth elements—essential for defense-grade magnets—remains unchallenged. Additionally, environmental concerns and price volatility in the rare earth market could hinder U.S. efforts. However, the strategic imperative to secure supply chains creates long-term investment opportunities in domestic processing, recycling, and alternative materials.

Conclusion

The U.S. legislative push to counter China's rare earth dominance and secure aviation supply chains reflects a broader strategy to mitigate geopolitical risks. While legislative and industrial efforts are gaining momentum, the path to self-sufficiency remains fraught with challenges. Investors and policymakers must prioritize innovation, international collaboration, and sustained funding to ensure resilience in critical sectors.

Comentarios

Aún no hay comentarios