Kardemir Karabuk Demir Celik Sanayi Ve Ticaret's Strategic Position in the Global Steel Market

Assessing Long-Term Growth Amid Infrastructure Shifts and Green Steel Transitions

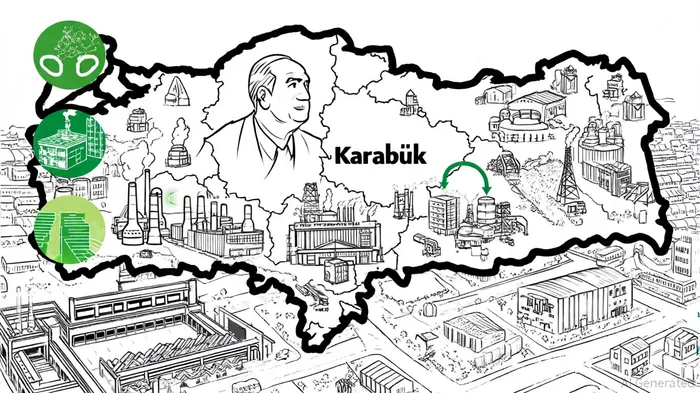

Kardemir Karabuk Demir Celik Sanayi Ve Ticaret A.S. (Kardemir), Turkey's largest integrated long steel producer, occupies a pivotal position in a global industry undergoing rapid transformation. With a production capacity of 2.5 million tons per year and a diversified product portfolio—including railway rails, rebars, and coke products—the company serves both domestic and international markets[1]. However, its long-term growth hinges on navigating two critical forces: shifting infrastructure demand and the global green steel transition.

Market Positioning and Infrastructure Demand

Kardemir's strategic base in Turkey—a country with robust infrastructure development plans—positions it to benefit from domestic demand. The company's products are integral to construction, mining, and transportation sectors, which remain growth drivers in Turkey's economy[2]. According to a report by Bloomberg, Turkey's infrastructure spending is projected to exceed $150 billion annually by 2027, driven by government initiatives to modernize transportation networks and urban infrastructure.

Globally, Kardemir exports to over 100 countries, though its market share in key regions like Europe and Asia remains opaque due to limited recent data[4]. This lack of transparency raises questions about its competitive positioning against peers such as ArcelorMittalMT-- or Tata Steel. However, its recent completion of a second vacuum plant—boosting annual production of high-quality railway wheels to 1 million metric tons—signals a focus on value-added products that could enhance export competitiveness[5].

Green Steel Transition: Progress and Challenges

The steel industry accounts for ~7% of global CO₂ emissions, making decarbonization a regulatory and reputational imperative[6]. Kardemir's alignment with the European Green Deal and Carbon Border Adjustment Mechanism (CBAM) underscores its awareness of these pressures. As of 2025, the company has completed 22 of 34 planned environmental projects in its third-phase sustainability plan, including a 30 MW captive power plant to reduce energy costs and emissions[7].

Notably, Kardemir's green cement investment through its subsidiary KARÇİMSA Çimento A.Ş.—a 1 million-ton clinker and slag grinding facility—demonstrates a cross-industry approach to sustainability[8]. Yet, the company's reliance on blast furnace (BF) and basic oxygen furnace (BOF) technologies—a carbon-intensive process—highlights a gap in its transition strategy. While it has explored hydrogen-based direct reduced iron (H2-DRI) and electric arc furnace (EAF) technologies in global context[9], concrete timelines or investment figures for adopting these methods remain undisclosed.

Financial Resilience and Risks

Kardemir's financials reflect a mixed picture. With a trailing twelve-month revenue of $1.68 billion and total equity of 36.84 billion Turkish lira as of 2023[10], the company has shown resilience despite a net loss of $36.168 million in June 2025[11]. This volatility may stem from fluctuating raw material costs and currency pressures, given Turkey's macroeconomic environment.

Investors must weigh these risks against Kardemir's long-term bets on green infrastructure. For instance, its partnership with UK-based Primetals Technologies to upgrade sinter plants in Karabük aims to optimize operations and reduce emissions[12]. Such projects align with global trends, where green-steel hubs are emerging in regions with low-cost renewable energy[13]. However, Kardemir's geographic concentration in Turkey—a country with limited renewable energy infrastructure—could hinder its ability to scale hydrogen-based production without significant external investment.

Future Outlook: Balancing Ambition and Execution

Kardemir's strategic roadmap suggests a dual focus: expanding high-margin products while mitigating environmental risks. Its 30 MW power plant and vacuum degassing facilities[14] are steps toward energy efficiency, but the company must accelerate adoption of transformative technologies like CCUS (carbon capture, utilization, and storage) or green hydrogen to meet the 1.5°C target outlined in the E3G 2023 Steel Policy Scorecard[15].

For investors, the key question is whether Kardemir can bridge the gap between its current operations and the low-carbon future. Its progress on 22 of 34 environmental projects[16] indicates operational discipline, but transparency around carbon reduction targets and capital allocation for green tech will be critical.

Conclusion

Kardemir Karabuk's strategic position in the global steel market is defined by its domestic infrastructure tailwinds and nascent green initiatives. While its production capabilities and export reach provide a solid foundation, long-term success will depend on its ability to pivot toward low-carbon technologies and secure a clear market share in key regions. For now, the company's alignment with European sustainability frameworks and incremental progress on decarbonization offer cautious optimism—but investors should monitor its next phase of investments closely.

Comentarios

Aún no hay comentarios