JLR's Phased Restart: A Test of Supply Chain Resilience and Investor Confidence

Jaguar Land Rover's (JLR) phased restart of manufacturing operations following a devastating cyberattack in early September 2025 has become a focal point for investors and industry analysts. The incident, which forced the shutdown of three major UK plants and disrupted global supply chains, exposed vulnerabilities in the automotive sector's reliance on digital infrastructure. Yet JLR's response-combining strategic financial innovation, government support, and methodical operational recovery-offers a blueprint for navigating crises while balancing short-term stability with long-term resilience.

A Methodical Restart: Prioritizing Security and Supply Chain Stability

JLR's phased restart began on 8 October 2025 at its Electric Propulsion Manufacturing Centre and Battery Assembly Centre in the West Midlands, UK, followed by stamping operations in Castle Bromwich, Halewood, and Solihull. By the week of 8 October, production lines for Range Rover models in Solihull and Nitra, Slovakia, had also resumed, according to JLR's restart announcement. This staggered approach reflects a prioritization of security and operational safety, with JLR collaborating with the UK's National Cyber Security Centre (NCSC) and law enforcement to ensure systems are fully secured before scaling up, according to Cybersecurity News.

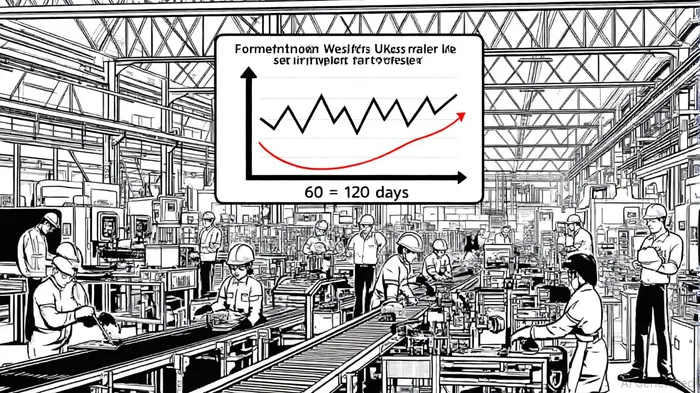

The restart is not merely about restarting machines but recalibrating relationships with suppliers. A new financing scheme, announced alongside the resumption of production, accelerates payments to qualifying suppliers by up to 120 days-double the standard 60-day post-invoice terms. Suppliers receive a majority prepayment upon order placement and a final "true-up" payment upon invoicing, with JLR covering associated financing costs during the restart phase, as detailed in JLR's announcement. This initiative, as noted by Sky News, aims to mitigate liquidity risks for smaller suppliers, which are often the most vulnerable in cascading disruptions.

Strategic Implications: Supply Chain Resilience as a Competitive Advantage

The cyberattack laid bare the fragility of JLR's supply chain, particularly for smaller vendors with limited financial buffers. By front-loading payments, JLR is not only stabilizing its immediate production needs but also signaling a shift toward more resilient supplier partnerships. According to Business Standard, this approach could set a precedent for how automakers manage risk in an era of increasing cyber threats.

However, challenges remain. Industry experts caution that even with accelerated payments, the restart's success hinges on resolving deeper issues, such as inventory gaps and the reputational damage from the attack. The UK government's £1.5 billion loan guarantee, while critical for preserving cash flow, also underscores the scale of systemic risk, as reported by Cybersecurity News. For JLR, the path forward requires balancing rapid recovery with investments in cybersecurity and supplier diversification.

Investor Confidence: A Balancing Act

Investor reactions have been mixed. On one hand, JLR's proactive measures-coupled with government backing-have reassured markets about its short-term viability. The stock has shown modest gains since the restart announcement, reflecting optimism about the company's ability to mitigate losses. On the other hand, the incident has reignited debates about corporate governance and risk management. As stated by a cybersecurity analyst in a recent Automotive Logistics article, "JLR's response is commendable, but investors must ask: Was this a one-off event or a symptom of broader systemic weaknesses?"

The key for investors lies in JLR's ability to translate this crisis into long-term value. The phased restart and supplier financing scheme demonstrate agility, but sustained confidence will depend on transparency about the cyberattack's root causes and the company's plans to prevent future incidents.

Conclusion: A Crucible for Leadership

JLR's restart is more than a technical exercise; it is a test of leadership in an increasingly volatile business environment. The company's strategic emphasis on supply chain resilience-through financial innovation, government collaboration, and operational discipline-offers a compelling case study for other firms navigating similar disruptions. For investors, the lesson is clear: resilience is not just about surviving shocks but reimagining systems to thrive in their aftermath.

Comentarios

Aún no hay comentarios