Intel and Apple: A Semiconductor Alliance for Innovation and Supply Chain Resilience

The semiconductor industry is on the cusp of a transformative partnership that could redefine global manufacturing dynamics and technological innovation. Intel's reported early-stage discussions with AppleAAPL-- to explore investment or collaboration in advanced chip manufacturing[1] have sparked significant investor interest. This potential alliance, centered on Intel's 14A process node and Apple's M-series chip requirements, represents a strategic convergence of semiconductor innovation and supply chain resilience. For investors, the implications are profound, touching on geopolitical risk mitigation, technological leadership, and the broader U.S. industrial policy agenda.

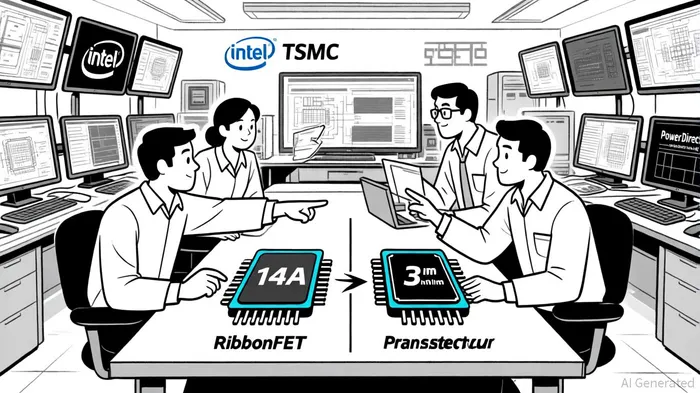

Intel's 14A Process: A Technological Leap for Foundry Ambitions

Intel's 14A process node, a 1.4nm-class technology, is a cornerstone of its foundry revival strategy. According to a report by Tom's Hardware, the 14A node delivers a 15-20% improvement in performance-per-watt over its predecessor, the 18A node, while offering a 1.3X increase in transistor density[2]. These advancements are driven by second-generation RibbonFET transistors and PowerVia PowerDirect technology, which optimize power delivery and reduce energy consumption[3]. Additionally, the introduction of “Turbo Cells” allows for mixed-performance design blocks, enabling tailored optimization for critical workloads like CPU and GPU acceleration[4].

For IntelINTC--, securing Apple as a customer or investor would validate its return to the foundry market. The company's CEO, Lip-Bu Tan, has emphasized that the 14A node's success hinges on capturing volume from major clients[5]. Apple's interest in the process—potentially for future M-series chips—could provide the scale needed to justify the high costs of advanced node development[6].

Apple's Strategic Diversification: Balancing Performance and Resilience

Apple's M-series chips, including the M4, are renowned for their performance and AI capabilities, leveraging TSMC's 3nm and N3E processes[7]. However, the company's reliance on a single foundry in Taiwan exposes it to geopolitical risks, particularly amid U.S.-China tensions and the potential for supply chain disruptions[8]. By exploring Intel's 14A node, Apple could diversify its manufacturing footprint, shifting some production to U.S.-based facilities under the CHIPS and Science Act[9].

This move aligns with broader industry trends. As noted by BCG, the U.S. is projected to increase its share of advanced wafer fabrication capacity from near-zero in 2022 to 28% by 2032, driven by $348 billion in private sector investments[10]. For Apple, this diversification could reduce costs through foundry competition while ensuring access to cutting-edge U.S. manufacturing.

Supply Chain Resilience: A Geopolitical and Economic Imperative

The semiconductor supply chain has long been centralized in Asia, with TSMC producing as many wafers annually as the entire U.S. industry[11]. This concentration poses risks for companies like Apple, which rely on high-performance chips for its Macs, iPhones, and AI-driven services. By partnering with Intel, Apple could mitigate these risks while supporting U.S. government initiatives to localize production[12].

Moreover, the partnership could strengthen Apple's relationship with the Trump administration, which has prioritized domestic manufacturing. The company's $600 billion commitment to U.S. manufacturing initiatives[13] could be further advanced through collaboration with Intel, aligning corporate strategy with national security goals.

Investment Implications and Market Outlook

The potential partnership has already had a measurable impact on Intel's stock, which surged 6% following news of the talks[14]. For investors, the key question is whether this collaboration will materialize into a formal agreement and how it might reshape the competitive landscape. If Apple adopts the 14A node, Intel could gain a foothold in the high-performance computing and AI markets, challenging TSMC's dominance[15].

However, challenges remain. The 14A node's higher per-wafer costs compared to TSMC's 3nm process[16] could limit its adoption unless Apple prioritizes resilience over cost. Additionally, Apple's current co-design process with TSMC has yielded highly optimized chips; switching to Intel would require significant engineering effort to achieve similar results[17].

Conclusion

Intel's potential partnership with Apple represents a pivotal moment for both companies and the semiconductor industry. For Intel, it offers a path to reclaim foundry leadership through advanced node innovation. For Apple, it provides a strategic hedge against geopolitical risks while supporting U.S. manufacturing goals. Investors should monitor the talks closely, as their outcome could influence not only stock valuations but also the global balance of power in chip manufacturing.

Comentarios

Aún no hay comentarios