Global Energy Transition Bottlenecks: The Gas Turbine Supply Chain Crisis and Its Implications for Investors

The global energy transition, long hailed as a race against time to decarbonize power systems, is now facing an unexpected bottleneck: a severe shortage of gas turbines. As the world grapples with surging electricity demand driven by AI-driven data centers, industrial electrification, and coal-to-gas transitions, the three dominant gas turbine manufacturers-GE Vernova, Siemens Energy, and Mitsubishi Power-are struggling to meet orders. With lead times stretching to five to seven years and costs for new combined-cycle gas plants exceeding $2,400 per kilowatt, the ripple effects are reshaping energy planning, investment strategies, and grid reliability frameworks, according to a Power Magazine report.

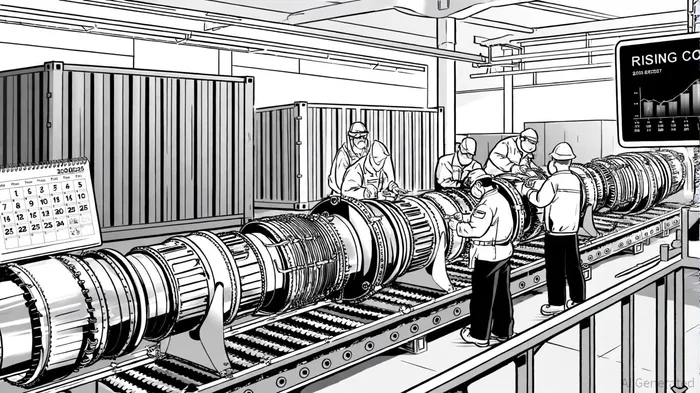

The Perfect Storm: Demand Surge Meets Flat Production Capacity

The root of the crisis lies in a mismatch between demand and supply. According to a Bloomberg feature, global gas turbine orders have surged due to AI infrastructure expansion and decarbonization efforts in emerging markets. However, the manufacturing capacity of the top three producers has remained largely stagnant for decades. Siemens Energy, for instance, reported a record backlog of €131 billion in 2025, with €16.4 billion in new gas turbine orders alone, Reuters reported. GE VernovaGEV--, the market leader in heavy-duty turbines, faces a $80 billion power backlog, while Mitsubishi Power has most of its 2027–2030 production slots already booked, according to a Gasturbine Hub analysis.

Data from S&P Global highlights that lead times for gas turbines have ballooned to 37 months in some cases, up from 24–36 months historically. This is compounded by supply chain bottlenecks for specialized components, such as high-temperature alloys and digital control systems, which are critical for advanced turbine models. Meanwhile, maintenance backlogs for existing turbines-many of which require overhauls every 8,000–24,000 operating hours-have further strained availability, as Power Engineering explains.

Production Constraints: A Race to Expand Capacity

All three manufacturers are investing to scale production, but the pace remains inadequate. GE Vernova plans to increase U.S. output to 70–80 heavy-duty turbines annually by 2026, up from 55 in 2024, via a $300 million facility expansion, the Bloomberg feature notes. Similarly, Mitsubishi Power aims to double its capacity but acknowledges that most new orders will not be fulfilled until 2028–2030, according to Young Research. Siemens Energy, however, has not disclosed specific production targets, citing persistent supply chain challenges, RMI notes in its analysis of near-term options for grid reliability (RMI).

Workforce limitations are another critical constraint. The specialized labor required to manufacture and service turbines-such as precision machinists and digital engineers-is in short supply, with training cycles often lagging behind demand. As noted by Wood Mackenzie, this labor gap is exacerbating delays in both new builds and maintenance cycles.

Implications for the Energy Transition and Investors

The consequences of these bottlenecks are far-reaching. For one, the coal-to-gas transition in developing nations is stalling. Countries like India and Indonesia, which rely on gas as a bridge to renewables, may be forced to extend coal plant lifetimes due to turbine shortages, Power Engineering warns in its coverage of turbine delays (Power Engineering). In developed markets, the U.S. Energy Information Administration projects a 270 GW gap in generation capacity by 2030, which cannot be reliably filled by new gas plants if current lead times persist, as reported by Greentech Lead.

Investors must also weigh the financial risks. A study by RMI found that the average cost of a new gas-fired plant has risen by 40% since 2020, driven by inflation, supply chain costs, and project delays. This has led some utilities to abandon proposed projects, as seen in Texas and California, where developers are now prioritizing alternatives like grid-scale battery storage and demand-response programs.

Strategic Opportunities Amid the Crisis

While the challenges are daunting, they also present opportunities. Companies offering grid-enhancing technologies-such as advanced inverters, virtual power plants, and AI-driven load management-stand to benefit from the urgent need for near-term reliability solutions. Additionally, firms specializing in turbine maintenance and spare parts could see increased demand as operators prioritize extending the life of existing assets.

For investors in turbine manufacturers, the key question is whether GE Vernova, Siemens Energy, and Mitsubishi Power can scale production sustainably. While capital expenditures are rising, the time required to bring new factories online (typically 3–5 years) means the industry will remain constrained through at least 2030.

Conclusion

The gas turbine supply chain crisis underscores a critical reality: the energy transition is not just a technological or policy challenge but a logistical and industrial one. For investors, the stakes are high. Those who recognize the interplay between manufacturing constraints, energy demand, and alternative solutions will be better positioned to navigate this pivotal phase of the global shift to cleaner power.

Comentarios

Aún no hay comentarios