Germany's Deepening Trade Deficit with China and Its Implications for European Manufacturing and Supply Chains

Germany's trade deficit with China has reached a critical inflection point. By 2025, the gap is projected to hit a record €87 billion ($101.46 billion), surpassing the previous high of €84 billion in 2022, according to a Cryptopolitan report. This imbalance is not just a statistical anomaly-it reflects a structural shift in global trade dynamics, driven by U.S. tariffs on Chinese goods and China's own industrial strategy. For European manufacturers and investors, the implications are profound: a race to diversify supply chains, mitigate geopolitical risks, and secure access to critical materials like rare earths and semiconductors.

The Drivers of the Deficit: Tariffs, Localization, and Sectoral Shifts

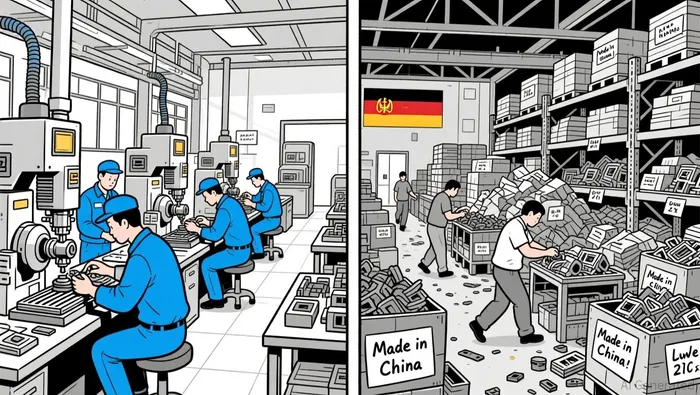

The surge in China's exports to Germany-up 11% year-to-date in 2025-stems from U.S. tariffs that have rerouted trade flows, as Coinotag analysis shows. Meanwhile, German exports to China have declined by over 11%, as Chinese firms increasingly produce goods locally, reducing reliance on imports, according to an Investing.com report. This dual pressure has pushed China back to the top of Germany's trade partner rankings, displacing the U.S., per OEC data.

Key sectors contributing to the deficit include machinery, electronics, and automotive components. Chinese goods, priced 20–30% lower than their European counterparts, are flooding the market, squeezing German manufacturers. For example, Schaeffler AG, a major German automotive supplier, recently sold its turbocharger business in China to a local firm, signaling a strategic retreat from direct competition, according to TradingView.

Strategic Diversification: The EU's Critical Raw Materials Act and Beyond

Germany and the EU are acutely aware of the risks posed by over-reliance on China for critical materials. The EU's Critical Raw Materials Act (CRM Act), implemented in May 2024, aims to reduce dependency by setting benchmarks for domestic production and recycling. By 2030, the EU targets 10% of annual raw material needs to be sourced domestically, 40% processed locally, and 25% recycled, as set out on a European Commission page.

Germany is also pivoting to alternative trade partners. A landmark 2024 Memorandum of Understanding (MoU) with Australia focuses on sustainable critical minerals, including rare earths and lithium, according to an Austrade analysis. Vietnam and the U.S. are additional targets, though challenges remain. Mining rare earths outside China is costly and environmentally complex, and geopolitical ties-such as the recent U.S.-China agreement to ease export restrictions-complicate diversification efforts, as reported in a DW article.

Implications for European Manufacturing: Competitiveness and Resilience

The trade deficit threatens Germany's industrial base. Low-cost Chinese imports are eroding margins in sectors like automotive and machinery, with some estimates suggesting job losses in the tens of thousands, according to a DW analysis. However, the crisis is also a catalyst for innovation. The EU's Global Gateway initiative, for instance, is funding infrastructure projects to strengthen supply chains in the Indo-Pacific, while Germany's Lithium Hydroxide Converter Guben project aims to localize battery production, according to a German Foreign Office report.

Investors should watch for two trends:

1. Supply Chain Resilience Plays: Companies investing in recycling technologies or domestic processing of rare earths (e.g., Umicore, BASF) could benefit from EU subsidies.

2. Trade Diversification Winners: Firms expanding into Vietnam or Australia-such as Siemens and ThyssenKrupp-are likely to see long-term gains as Germany rebalances its trade relationships.

The Road Ahead: Balancing Risk and Opportunity

While Germany's efforts to diversify are gaining momentum, structural challenges persist. China's dominance in refining rare earths (over 80% of global capacity) means even diversified supply chains will require collaboration with Beijing, as noted in a Benzinga piece. The EU's CRM Act is a step forward, but achieving 2030 targets will demand regulatory agility and private-sector investment.

For investors, the key takeaway is clear: the Germany-China trade deficit is a symptom of a broader shift in global manufacturing. Those who position themselves to capitalize on supply chain resilience-whether through tech-driven recycling, strategic partnerships, or alternative materials-stand to outperform in an era of geopolitical uncertainty.

Comentarios

Aún no hay comentarios