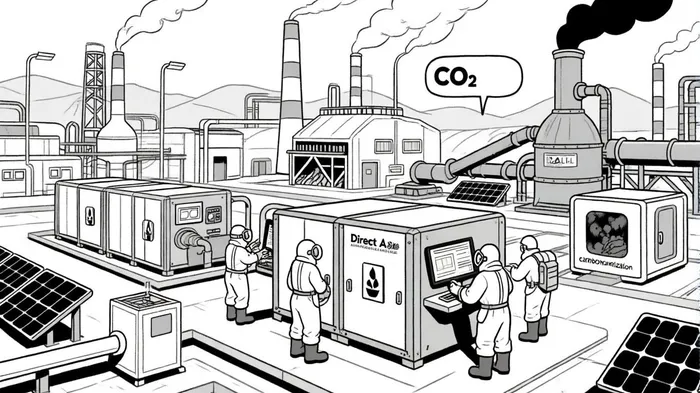

Direct Air Capture (DAC) Technology in Industrial Sectors: Scalable Deployment and ROI Potential in High-Emission Industries

The industrial sector, responsible for nearly 30% of global CO₂ emissions according to a Nature Communications review, faces an urgent need for scalable decarbonization solutions. Direct Air Capture (DAC) technology, once a niche concept, is now emerging as a critical tool for addressing hard-to-abate emissions in industries like cement, steel, and chemicals. While challenges remain, recent advancements in cost reduction, integration with industrial processes, and policy support are reshaping DAC's ROI potential and scalability.

DAC in Cement: Carbon-Closed Loops and Cost Innovation

The cement industry, which emits 8% of global CO₂ according to a Grand View Research report, is pioneering DAC integration through innovative approaches. For example, cement kiln waste heat is being repurposed to regenerate DAC sorbents, reducing energy costs, as described in a Cemteck article. Additionally, the same Cemteck article notes that captured CO₂ is being mineralized into cementitious materials, creating a carbon-closed loop. A 2025 techno-economic study projects that DAC-to-urea systems could lower capture costs to $154–$263 per ton of CO₂ under optimistic renewable energy scenarios. While payback periods remain long due to high upfront capital expenditures (CAPEX), that study also finds the ability to monetize captured CO₂ as a feedstock for high-demand products like urea and synthetic fertilizers is improving economic viability.

DAC in Steel: Complementing Green Hydrogen and CCUS

Steel production, responsible for 7% of global emissions according to a Skytree report, is exploring DAC to address residual emissions from green hydrogen and carbon capture, utilization, and storage (CCUS) systems. Pilot projects using cryogenic carbon capture (CCC) have achieved 95% capture rates, as reported in pilot case studies, though energy demands remain a hurdle. A 2025 assessment based on those case studies notes that integrating DAC with existing steel facilities could reduce costs by leveraging waste heat and industrial infrastructure. However, the high operational expenditure (OPEX) of $400–$1,000 per ton of CO₂ cited in a Belfer Center analysis underscores the need for policy incentives like carbon pricing to improve ROI.

DAC in Chemicals: Synthetic Fuels and Market Demand

The chemical industry, which accounts for 10% of industrial emissions (Grand View Research), is leveraging DAC to produce synthetic fuels and carbon-neutral chemicals. For instance, captured CO₂ is being used as a feedstock for methanol and urea, creating revenue streams that offset DAC costs, as Skytree notes. A 2025 market report projects the global DAC market to grow at a 61.15% CAGR, reaching $1.7 billion by 2030 (Grand View Research). While net present value (NPV) calculations for specific projects remain scarce, the industry's focus on innovation-such as distributed DAC systems powered by geothermal energy-is highlighted in a Nature perspective, suggesting improving scalability.

Economic Barriers and Pathways to ROI

DAC's current cost range of $250–$600 per ton of CO₂ is a significant barrier, according to an MDPI analysis, but learning curves and economies of scale are expected to drive costs below $100 per ton by 2030, per a ChemEng Consulting blog. Private investments ($1.1 billion in 2024) and government funding ($3.5 billion allocated) are accelerating deployment, as reported in an Allied Offsets blog. For example, 1PointFive's Stratos project in Texas, with a 500 ktCO₂/yr capacity, demonstrates the potential for gigaton-scale deployment according to Allied Offsets' global tracking. However, achieving profitability will require:

1. Policy Support: Carbon pricing or tax credits to bridge the cost gap.

2. Energy Integration: Transitioning to renewable energy to avoid undermining climate benefits, as modeled in a PRISM scenario.

3. Industrial Synergies: Leveraging waste heat and byproducts to reduce OPEX, as shown in a Frontiers analysis.

Conclusion: A High-Risk, High-Reward Opportunity

DAC's scalability and ROI in high-emission industries remain contingent on technological breakthroughs, policy frameworks, and market demand. While payback periods and internal rates of return (IRR) are not yet well-defined for most projects, the sector's rapid growth and strategic integration with industrial processes suggest a compelling long-term investment case. For investors, the key lies in balancing early-stage risks with the transformative potential of DAC to redefine decarbonization in the 21st century.

Comentarios

Aún no hay comentarios