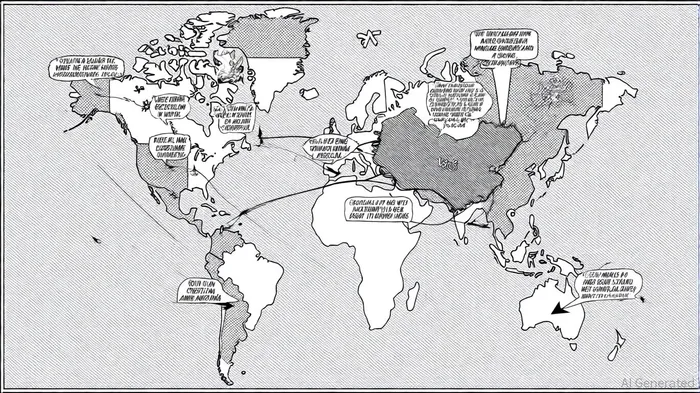

China's Rare-Earth Gambit: Supply Chain Vulnerabilities and the Rise of Alternatives in 2025

In 2025, China's rare-earth export policies have evolved into a geopolitical weapon, tightening its grip on a sector it controls 90% of global refining capacity. The Ministry of Industry and Information Technology (MIIT) announced sweeping changes in August 2025, including the inclusion of imported raw materials under export quotas and stricter controls on technologies for mining, smelting, and magnet production in a report titled China tightens rare-earth rules. These measures, framed as "national security" safeguards, explicitly target military applications and foreign entities deemed threats, according to the Rare Earth Recycling Market report. The timing aligns with U.S.-China trade tensions, as Beijing retaliated against U.S. tariffs by adding rare earths to its export restriction list in April 2025, as that report noted.

Supply Chain Vulnerabilities and Industry Impact

China's dominance in rare-earth processing creates systemic risks for global industries reliant on these materials. Rare earths are critical for electric vehicle (EV) motors, wind turbine generators, and defense-grade alloys. For instance, neodymium and dysprosium-used in high-performance magnets-are essential for EVs, which are projected to account for 30% of global car sales by 2030, according to the Global rare-earths industry report. The new quotas, which now apply to foreign companies sourcing rare earths from China, have created uncertainty for manufacturers. As detailed in the Rare Earth Recycling Market Forecast, The New York Times warned that "The restrictions could disrupt renewable energy projects and defense contracts, as companies scramble to secure alternative supplies."

Recycling and Alternative Materials: The New Frontier

The tightening grip on rare-earth exports has accelerated investments in recycling and substitute materials. The global rare-earth recycling market, valued at $0.601 billion in 2025, is projected to grow at a 5.76% CAGR, reaching $0.94 billion by 2034 (the Rare Earth Recycling Market report cited above). Companies like Cyclic Materials and Ionic Rare Earths are leading the charge. Cyclic Materials, for example, is scaling up its rare-earth magnet recycling operations to process 500 metric tons annually by 2025, using advanced chemical processes to recover materials from EVs and wind turbines (the Rare Earth Exchange briefing noted this). Meanwhile, Ionic Rare Earths' technology for separating rare earths from scrap is set to receive significant government funding in Northern Ireland, according to the market forecast referenced earlier.

Technological innovations are also reshaping the landscape. Flash joule heating, developed by Rice University, enables the recovery of rare earths from electronic waste with 90% purity, using fewer steps and lower energy than traditional methods (as discussed in the market forecast). Metallurgical recycling, which dominates the market due to its cost-effectiveness, is being scaled by firms like Hitachi Metals and Shenghe Holding (see the Rare Earth Recycling Market report).

Geopolitical and Policy Drivers

Governments are playing a pivotal role in diversifying supply chains. The U.S. Inflation Reduction Act and the EU's Critical Raw Materials Act incentivize domestic production and recycling, according to the Global rare-earths industry analysis. In Australia, Lynas Rare Earths operates a processing plant in Malaysia, while Arafura Rare Earths nears completion of its Nolans project in Australia (the Rare Earth Recycling Market report provides project details). Indonesia and Brazil are also emerging as key players, with Indonesia establishing a national agency for critical minerals and Brazil advancing rare-earth processing projects (as noted in the market forecast).

Investment Opportunities and Risks

Investors should focus on three areas:

1. Recycling Technologies: Companies like Cyclic Materials and Illumynt (specializing in magnet recycling) are positioned to benefit from circular economy trends (see the Rare Earth Exchange coverage).

2. Alternative Materials: MP Materials (U.S.) and Critical Metals Corp (Greenland project) are developing non-Chinese supply chains for heavy rare earths, and innovations in ceramic magnets, graphene, and iron nitride (which outperforms traditional magnets in energy product metrics) offer long-term potential (detailed in the Rare Earth Recycling Market report).

3. Policy-Driven Projects: The Minerals Security Partnership and EU alliances are funding infrastructure to reduce reliance on China (the Global rare-earths industry analysis outlines these initiatives).

However, challenges remain. High production costs for substitutes like graphene, environmental concerns in mining, and China's entrenched processing dominance could slow progress (the Global rare-earths industry report warns of these hurdles).

Conclusion

China's rare-earth policies are a wake-up call for global industries. While the immediate risks are clear, the crisis is spurring innovation in recycling and alternative materials. Investors who align with circular economy principles and geopolitical trends-such as the U.S. Defense Production Act and EU supply chain resilience initiatives-stand to benefit from a sector in transformation. The key lies in balancing short-term volatility with long-term structural shifts toward sustainability and diversification.

Comentarios

Aún no hay comentarios