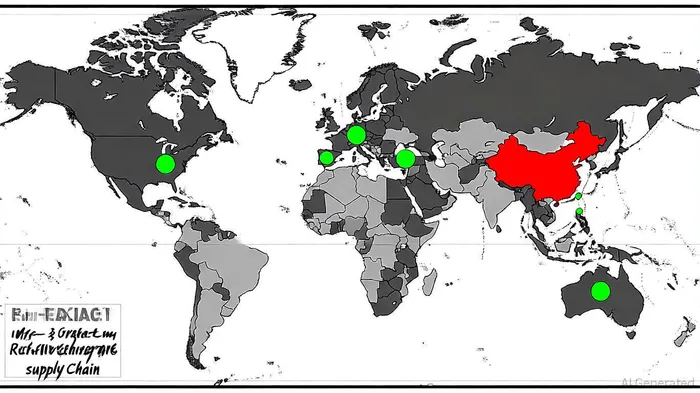

China's Rare-Earth Export Curbs and the Semiconductor Supply Chain: Strategic Investment Opportunities in Alternatives and Recycling

In 2025, China's aggressive tightening of rare-earth export controls has sent shockwaves through global supply chains, particularly in the semiconductor and defense sectors. By adding five rare-earth elements to its restricted list and extending controls to technologies used in mining and processing, Beijing has weaponized its dominance in the sector-accounting for over 90% of global refining capacity-to assert geopolitical leverage, according to Investing News. These measures, explicitly targeting military and semiconductor applications, have forced automakers in Europe and Japan to halt production, according to a CSIS analysis, and driven prices for critical elements like dysprosium and terbium to record highs, according to a DataMarketView report. For investors, this crisis underscores a pivotal shift: the urgent need to diversify supply chains and invest in alternatives and recycling technologies to mitigate risks.

The Semiconductor Supply Chain Under Threat

Rare-earth elements (REEs) are indispensable for high-performance magnets used in semiconductors, AI hardware, and defense systems. China's new export rules require foreign producers using Chinese-sourced materials or technologies to obtain licenses, with applications for defense use outright rejected, the CSIS analysis notes. This has directly impacted chipmakers in South Korea and Taiwan, such as TSMCTSM-- and Samsung, which rely on rare-earth-derived technologies for advanced manufacturing, as reported in Technology Review. According to the CSIS report, U.S. defense industries now face heightened vulnerabilities as Beijing restricts access to materials critical for radar systems, guided missiles, and next-generation semiconductors.

The U.S. response has been twofold: accelerating domestic production and investing in recycling. The Department of Defense's $400 million investment in MP Materials' Mountain Pass mine and its planned rare-earth magnet factory in Texas exemplify this strategy, according to a BISI report. However, experts caution that building fully independent supply chains will take years, leaving the market exposed to short-term volatility, the BISI report warns.

Recycling and Alternatives: The New Frontier for Investors

As China's export curbs exacerbate supply shortages, recycling and substitution technologies are emerging as critical investment opportunities. Companies like Cyclic Materials and CoTec Holdings are leading the charge. Cyclic Materials, a Toronto-based firm, is scaling its "spoke-hub" recycling model to recover rare earths from electric vehicles, wind turbines, and hard drives, as covered in Technology Review. Its proprietary REEPure process enables the extraction of high-purity rare earth oxides, bypassing China's dominance in refining, according to Resource Recycling. Similarly, CoTec's Hydrogen Processing of Magnet Scrap (HPMS) technology allows for the recovery of magnet materials without energy-intensive smelting or acid leaching, offering a sustainable alternative, as an Investing News article highlights.

The global rare-earth recycling market is projected to grow from $5 billion in 2025 to $15 billion by 2033, driven by environmental regulations and demand from clean energy sectors, DataMarketView projects. This growth is further supported by U.S. and EU policies such as the Inflation Reduction Act and the Critical Raw Materials Act, which incentivize domestic recycling and processing, a Resource Recycling piece notes.

Strategic Companies and Geopolitical Implications

Beyond recycling, innovation in rare-earth alternatives is gaining traction. Ceramic magnets, graphene-based materials, and aluminum alloys are being developed to reduce reliance on REEs in electric motors and sensors, as noted in Technology Review. Meanwhile, U.S.-based firms like Vulcan Elements and ReElement Technologies are pioneering non-Chinese processing methods. Vulcan's partnership with ReElement, which uses chromatography to extract rare earths, positions it to compete globally in magnet production, according to Mining Technology.

China's export curbs are part of a broader "lawfare" strategy, where regulatory frameworks are used to shape global standards and assert influence, a trend Resource Recycling has documented. This trend mirrors the U.S. Foreign Direct Product Rule and highlights the growing contest for control over critical supply chains. For investors, the key lies in balancing short-term exposure to price volatility with long-term bets on resilient technologies.

Conclusion: Navigating the New Rare-Earth Landscape

China's 2025 export restrictions have exposed vulnerabilities in global supply chains but also created opportunities for innovation. Investors should prioritize companies developing recycling technologies, alternative materials, and non-Chinese processing capabilities. While geopolitical tensions and market volatility remain risks, the push for supply chain resilience-backed by government incentives and ESG-driven demand-positions this sector as a cornerstone of future economic security.

As the race to secure rare-earth independence intensifies, the winners will be those who adapt to a world where resource control is as much about technology as it is about geopolitics.

Comentarios

Aún no hay comentarios