China's Rare Earth Constraints and ASML's Lithography Dilemma: Navigating Supply Chain Vulnerabilities in a Geopolitical Age

The global semiconductor industry is facing a perfect storm of supply chain fragility and geopolitical tension, with China's 2025 rare earth export controls at the epicenter. These restrictions, which require case-by-case licenses for products containing more than 0.1% Chinese-origin rare earth elements, have directly targeted critical components used in ASML's EUV lithography systems-machines that define the cutting edge of chip manufacturing, according to a a TrendForce report. For ASMLASML--, the implications are profound: delays in shipments of its already 12–18-month lead-time EUV systems could ripple through the entire semiconductor value chain, from foundries like TSMC to end-user markets in AI and automotive technologies, as detailed in a Rare Earth Exchanges analysis.

The Lithography Bottleneck: Rare Earths as a Strategic Commodity

ASML's EUV machines rely on rare earth elements such as neodymium, dysprosium, and cerium oxide for precision components. Neodymium-iron-boron and samarium-cobalt magnets are essential for brushless DC motors and magnetic levitation systems, while cerium oxide is used in chemical mechanical polishing (CMP) processes, as previously reported by TrendForce. China's export curbs now force foreign firms to navigate a labyrinth of licensing requirements, creating bottlenecks in both production and re-exports. As Tom's Hardware reports, ASML has already braced for weeks-long delays in shipments, compounding existing lead times and threatening its 2026 growth projections.

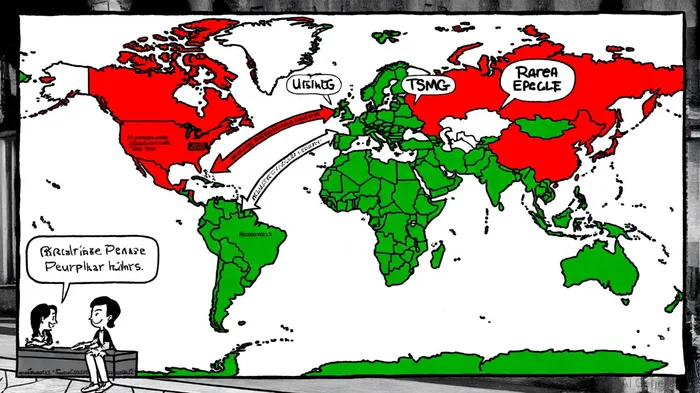

The geopolitical stakes are high. China controls over 80% of global rare earth processing and refining capacity, according to TS2, leveraging its dominance to amplify trade tensions. The U.S. and EU, which lack domestic refining infrastructure, are scrambling to build alternatives. The EU's Critical Raw Materials Act aims to produce 7,000 tons of rare earth magnets domestically by 2030, per a BISI report, while the U.S. has backed projects like Lynas Rare Earths' Texas facility, as noted in an OilPrice article. However, these efforts face years of development, leaving the industry exposed in the short to medium term.

ASML's Strategic Response: Investments, Partnerships, and Stockpiling

ASML is not standing idle. The company has deployed €1.2 billion into strategic equity investments to secure supply chain capacity for its High NA EUV roadmap, according to ASML earnings release, a critical next-generation technology. It has also stockpiled rare earth materials to buffer short-term demand, leveraging its long lead times to mitigate immediate disruptions (as reported by Tom's Hardware). Additionally, ASML is collaborating with partners in the Netherlands and U.S. to identify alternative rare earth sources and requalify substitutes-a process that could take years, according to a Techovedas article.

Yet, these measures are not foolproof. ASML's CFO, Roger Dassen, has acknowledged that China's export rules could expand to other rare earth elements, creating a "structural challenge" for global revenue, as noted in a TrendForce piece. The company's pivot to AI-driven tools and advanced packaging solutions, while promising, cannot fully offset the physical constraints of rare earth scarcity (see ASML's earnings release).

Geopolitical Risks and the Path Forward

The rare earth crisis underscores a broader vulnerability in global tech dependencies. As China tightens its grip, the U.S. and EU are accelerating efforts to diversify supply chains, but progress is slow. For instance, the EU's strategic reserves initiative, modeled after energy stockpiles, and international projects in Greenland and Australia, remain unproven at scale, as summarized in Rare Earth Exchanges' roundup. Meanwhile, Trump's threatened 100% tariffs on Chinese goods could further destabilize trade flows, a risk highlighted by TS2.

For investors, the key question is whether ASML's strategic investments can outpace the geopolitical and supply chain headwinds. While the company's €1.2 billion bet and AI integration signal resilience, the long-term outlook hinges on the success of global diversification efforts. Until alternative supply chains mature, ASML-and the semiconductor industry-will remain at the mercy of China's rare earth policies.

Conclusion: A Race Against Time

China's rare earth controls have transformed a technical supply chain issue into a geopolitical flashpoint. For ASML, the path forward requires balancing short-term stockpiling with long-term diversification, all while navigating an unpredictable regulatory landscape. Investors must weigh the company's strategic investments against the reality that replicating China's integrated rare earth supply chain is a multi-decade endeavor. In this high-stakes environment, patience and a diversified portfolio may be the only safeguards against volatility.

Comentarios

Aún no hay comentarios