China's Contradictory Smartphone Market Dynamics in 2026

China's smartphone industry in 2026 is a study in contradictions. On one hand, it is a global leader in AI-driven manufacturing efficiency, with automation, robotics, and predictive analytics reshaping production lines. On the other, it faces margin pressures from a perfect storm of rising component costs, geopolitical reallocations, and a global memory chip shortage. These dynamics create a market where structural strength coexists with operational fragility, offering both risks and opportunities for investors.

Supply Chain Reallocation: Reverse Globalization and Strategic Hedging

The industry's supply chain is no longer centralized in China. Companies are adopting reverse globalization strategies, offshoring and nearshoring to regions like Vietnam, the U.S., and the Middle East to mitigate geopolitical risks and secure market access. For example, SYJ Molding Technologies has opened U.S. facilities to improve customer proximity, while Malaysia is being leveraged for high-volume production, with China retaining its role as a hub for R&D and centralized innovation. This shift is not purely cost-driven but reflects a broader intent to diversify risk.

However, China's smartphone manufacturing service market was valued at $9.72 billion in 2025, with a projected CAGR of 12.89% through 2033, driven by robust infrastructure, skilled labor, and government incentives. Even as companies like JD Metal Crafts use cross-border e-commerce platforms to deliver products globally within weeks, China's role as a technological and logistical hub persists.

AI-Driven Efficiency vs. Margin Erosion

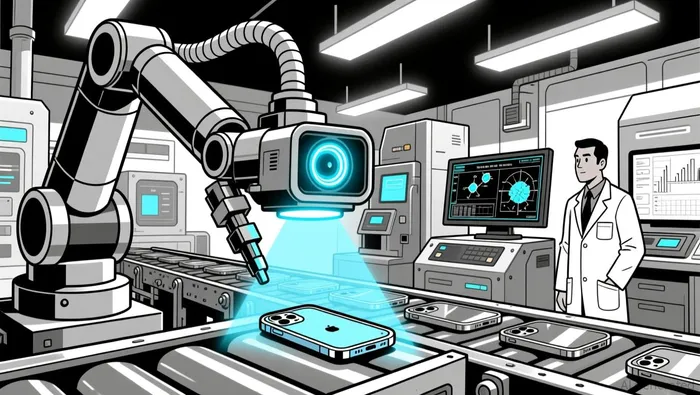

AI integration has revolutionized manufacturing, but it has also introduced new financial challenges. Chinese smartphone makers are adopting AI-powered quality control systems,  , digital twins, and predictive maintenance, with Weichai Power achieving 99% equipment coverage in visual recognition systems. By 2027, AI integration across key manufacturing domains is expected to exceed 70%, with a target of 90% by 2030.

, digital twins, and predictive maintenance, with Weichai Power achieving 99% equipment coverage in visual recognition systems. By 2027, AI integration across key manufacturing domains is expected to exceed 70%, with a target of 90% by 2030.

Yet, these gains are offset by rising costs. A global memory chip shortage, driven by AI data centers' insatiable demand for DRAM and NAND, has pushed component prices upward. Low-end smartphones priced below $200 now face a 20–30% increase in bill-of-materials costs, while mid- and high-end models see 10–15% hikes. This has forced manufacturers like TCL, Xiaomi, and Huawei to pass costs to consumers, squeezing already thin margins. Apple and Samsung, with stronger financial reserves and long-term supply agreements, have fared better, maintaining product specifications and market share.

Premiumization and Structural Shifts

The market is undergoing a "strong structure, weak volume" phase, with growth concentrated in premium price tiers (¥3,000–6,000 and ¥9,000+) rather than broad demand recovery. High-end models with AI features, advanced imaging, and improved performance are outpacing standard versions by 20% YoY growth compared to 5% for mid-range devices. This trend is driven by flagship features trickling down to mid-tier models, but mid-range demand remains weak due to cautious consumer spending.

Chinese tech giants like Xiaomi are investing heavily in AI-driven "dark factories," where fully automated systems produce one smartphone per second with minimal human intervention. Such facilities align with the "Made in China 2025" initiative, which has boosted capabilities in EVs and robotics but lagged in semiconductors and biomedicine.

Contradictions in AI Integration and Chip Shortages

Chinese firms are innovating to circumvent chip shortages. Cambricon Technologies aims to triple its AI accelerator production to 500,000 units in 2026, despite SMIC's low-yield N+2 process and reliance on imported HBM. Meanwhile, Alibaba and ByteDance are training AI models in Southeast Asian data centers to bypass U.S. export restrictions, enabling rapid development of large language models like Qwen.

However, these strategies highlight systemic vulnerabilities. Domestic semiconductor manufacturing lags behind global standards, and reliance on imported memory chips remains a bottleneck. JPMorgan analysts note that while chip shortages are not an immediate crisis, they will persist due to slow domestic improvements.

Financial Resilience and Strategic Priorities

Despite challenges, China's smartphone industry is projected to grow to $129.9 billion in 2026, driven by 5G adoption and product upgrades. Companies are leveraging AI-driven demand forecasting and inventory optimization to reduce costs, with early adopters reporting 15% inventory savings. Yet, 80% of firms miss AI infrastructure forecasts by over 25%, and 84% face significant margin erosion.

Premiumization and strategic supply chain reorganization are key to financial resilience. For example, rugged smartphone manufacturers are integrating IoT-enabled production and blockchain-based procurement systems to reduce costs and improve responsiveness. However, the broader industry's reliance on high-end semiconductors-where China remains dependent on U.S. and Taiwanese suppliers-limits long-term stability.

Conclusion: Navigating the Contradictions

China's smartphone market in 2026 is defined by a tension between AI-driven efficiency and margin pressures, between domestic innovation and global supply chain dependencies. For investors, the key lies in identifying firms that can balance these forces: those with strong R&D capabilities to absorb AI costs, diversified supply chains to mitigate geopolitical risks, and pricing power to navigate component shortages. While the path to profitability is fraught, the structural shift toward premiumization and AI integration offers a glimpse of long-term resilience-even if the road ahead remains bumpy.

Comentarios

Aún no hay comentarios