BorgWarner's Strategic Expansion in China's NEV Market: A Blueprint for Electrification Leadership

China's new energy vehicle (NEV) market is on a trajectory to dominate the global EV ecosystem, with electric vehicles projected to account for 80% of total car sales by 2030. For electrification leaders like BorgWarnerBWA--, this represents both a challenge and an unprecedented opportunity. The company's recent strategic moves in China—ranging from cutting-edge technological partnerships to localized manufacturing—position it as a key player in the race to define the next era of mobility.

Technological Innovation: The Core of BorgWarner's Competitive Edge

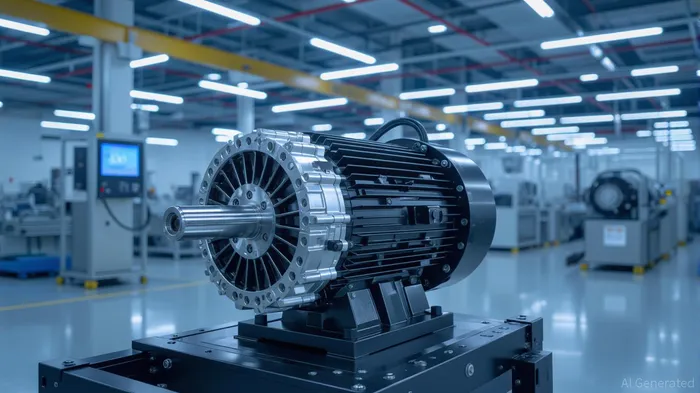

BorgWarner's 2025 expansion in China is anchored by its ability to deliver next-generation electrification solutions tailored to the region's unique demands. The company's ultra-short hairpin welding technology, which reduces motor size by over 5mm while increasing power density, directly addresses the need for compact, high-efficiency components in China's tightly regulated CLTC efficiency standards. This innovation not only improves performance but also reduces material costs—a critical factor in a market where price sensitivity remains high.

Equally compelling is BorgWarner's electric cross differential (eXD) system, which dynamically redistributes power between wheels to enhance handling and traction. In a market where SUVs and larger vehicles dominate EV sales, eXD's ability to optimize stability during high-speed driving and sharp turns aligns perfectly with Chinese consumers' preferences. The technology's adoption by a leading Chinese OEM underscores its value, particularly as automakers seek to differentiate their offerings in a crowded market.

Localized Production: A Strategic Response to Supply Chain Realities

BorgWarner's decision to establish a new manufacturing base in Wuhu, China, is a masterstroke in a market where supply chain resilience and cost efficiency are paramountPARA--. The facility, equipped with intelligent manufacturing lines capable of producing multiple motor platforms on shared lines, is expected to increase production capacity by over 40% in 2025 alone. This localized approach reduces lead times, cuts transportation costs, and mitigates risks associated with global supply chain volatility—factors that have historically disadvantaged foreign suppliers in China.

The Wuhu plant also reflects BorgWarner's long-term commitment to the region. By co-locating production with its key Chinese OEM partners, the company is not only securing a stable customer base but also fostering deeper R&D collaborations. This strategy mirrors the playbook of global EV leaders like TeslaTSLA--, which has leveraged localized manufacturing in Shanghai to dominate the Chinese EV market.

Strategic Partnerships: Building a Recurring Revenue Model

BorgWarner's partnerships with Chinese OEMs are not one-off transactions but part of a broader, multi-year collaboration. For instance, its dual inverter technology—designed to control two motors via a single controller—has been in development with a major Chinese automaker since 2021. The project, set to begin mass production by year-end 2025, features proprietary packaging that reduces thermal resistance by 50% compared to traditional cooling systems. This not only enhances power density but also ensures compliance with China's stringent emissions regulations.

Such partnerships are critical in a market where OEMs prioritize suppliers that can offer scalable, cost-effective solutions. BorgWarner's decade-long relationship with its primary Chinese customer, combined with its recent contract wins for 400V high-voltage hairpin motors, suggests a recurring revenue model that could drive consistent growth.

Competitive Landscape: Navigating a Crowded Field

While BorgWarner faces competition from global giants like ZF Friedrichshafen and Aisin Seiki, its localized R&D and manufacturing strategy gives it a distinct advantage. Chinese suppliers, though cost-competitive, often lack the technological sophistication required for high-end applications like eXD and dual inverter systems. Meanwhile, ZF's dominance in multi-speed transmissions is offset by its slower adoption of platform-based motor designs, a gap BorgWarner has successfully filled.

The company's financials further reinforce its competitive position. In Q2 2025, eProduct sales surged 31% year-over-year, contributing to a 10.3% adjusted operating margin. With full-year sales guidance raised to $14.0–$14.4 billion, BorgWarner is demonstrating the scalability of its electrification business.

Investment Implications: Positioning for Long-Term Gains

For investors, BorgWarner's China strategy offers a compelling case. The company is not merely riding the EV wave but actively shaping it through innovation and strategic alignment with market leaders. Its Wuhu facility and dual inverter program are expected to generate revenue streams for years, while its partnerships with Chinese OEMs provide a buffer against over-reliance on any single market.

However, risks remain. Regulatory shifts, such as potential changes in China's subsidy policies, or a slowdown in NEV adoption could impact growth. Yet, given the government's stated commitment to achieving 80% EV penetration by 2030, these risks appear manageable.

Conclusion: A Win-Win for Electrification and Investors

BorgWarner's expansion in China is a textbook example of how a global supplier can leverage localized production, strategic R&D, and deep OEM partnerships to thrive in a high-growth market. As the NEV ecosystem matures, the company's focus on efficiency, scalability, and innovation will likely translate into sustained profitability. For investors seeking exposure to the electrification transition, BorgWarner represents a well-positioned bet in a market where the winners will define the future of mobility.

Comentarios

Aún no hay comentarios