Assessing Geopolitical and Climate Risks in Global Automaker Valuations

The automotive industry is at a crossroads, with geopolitical and climate risks reshaping valuation dynamics for original equipment manufacturers (OEMs) and suppliers. From 2023 to 2025, automakers have faced a perfect storm of trade wars, semiconductor shortages, and climate-related disruptions, forcing a reevaluation of supply chain strategies. This analysis examines how supply chain resilience—driven by diversification, localization, and technology investments—is becoming a critical determinant of automaker valuations, while operational risk exposure continues to erode profitability.

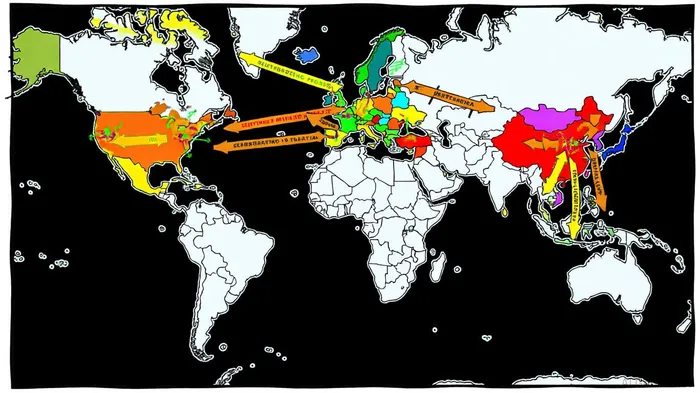

Geopolitical Risks and Supply Chain Fragility

Geopolitical tensions, particularly the U.S.-China trade war and regional conflicts, have disrupted access to critical materials like semiconductors and rare earth elements. A McKinsey report highlights that geopolitical risk undermines global supply chain resilience, especially in regions with weak property rights, leading to reduced trade credit and higher inventory costs [1]. For example, European premium brands saw weighted tariff rates surge from 1.7% in May 2024 to 18.2% in May 2025, directly impacting pricing strategies and profit margins [2]. J.P. Morgan estimates that combined tariffs on vehicles and parts will cost automakers $41 billion in the first year, rising to $52 billion by year three, with an average $2,580 per-vehicle cost increase [3].

General Motors and FordF-- are emblematic of the financial strain. GMGM-- absorbed $1.1 billion in tariff costs in Q2 2025 alone, while Ford anticipates a $3 billion annual impact. These pressures are forcing automakers to shift from traditional 90-day inventory models to more agile systems, prioritizing flexibility over lean production [4].

Climate Risks and Operational Exposure

Climate-related disruptions, including extreme weather events and resource scarcity, are compounding supply chain vulnerabilities. Research from S&P Global Mobility notes that environmental disruptions are pushing automakers to adopt flexible production models and secure strategic sourcing for rare materials [5]. For instance, the shortage of rare earth elements for electric vehicle (EV) motors has exposed bottlenecks in the EV transition, with some OEMs exploring rare-earth-free motor technologies to mitigate risks [6].

The financial toll is evident: Bain & Company reports that OEM EBIT margins fell to 5.4% in Q1 2025, a 40% decline from 2021 peaks, due to inflation, high interest rates, and dual production of internal combustion engines and EVs [7]. Suppliers, however, have outperformed OEMs, with EBIT margins at 6% in Q1 2025, though they face liquidity challenges from OEM cost-cutting demands [7].

Resilience Strategies and Valuation Implications

To counter these risks, automakers are investing in three core strategies:

Diversification and Localization

Nearshoring and in-sourcing are reducing dependencies on single regions. German automakers are building battery gigafactories in Eastern Europe to bypass Asian supply chains, while TeslaTSLA-- and Hyundai have shifted battery production to Mexico and Southeast Asia [8]. This localization reduces transportation costs but introduces new risks, such as fragmented platforms and higher capital expenditures [9].Technology Investments

Digital tools like AI, cloud computing, and digital twins are enabling real-time supply chain monitoring. BCG highlights that OEMs using digital twins to simulate risk scenarios have improved decision-making and inventory flexibility [10]. For example, Ford's use of AI-driven analytics has reduced semiconductor shortage impacts by securing volume commitments with chip manufacturers [11].Strategic Resilience Frameworks

Companies are embedding resilience into long-term planning, using scenario-based modeling to anticipate disruptions. Deloitte's 2023 Automotive Supplier Study notes that suppliers are navigating rising debt and operational complexity by aligning with OEMs' electrification goals [12].

These strategies are directly influencing valuation metrics. Automakers with robust resilience frameworks, such as StellantisSTLA-- (post-merger) and Tesla, have seen improved EBITDA margins and stock performance compared to peers with fragmented supply chains [13]. Conversely, firms like Ford, which face margin compression from input costs, trade at lower P/E ratios (10.2x vs. GM's 12.5x) [14].

Investor Sentiment and Future Outlook

Investor sentiment is increasingly tied to supply chain resilience. A report by S&P Global Mobility notes that companies with diversified supplier networks and localized production attract higher valuations, as they are perceived as better equipped to handle disruptions [15]. For example, BYD's aggressive localization in China and Southeast Asia has driven its stock to a 25% premium over traditional automakers [16].

However, challenges remain. The European Union's 2030 emissions targets and U.S. Inflation Reduction Act (IRA) are accelerating EV investments but also creating regulatory uncertainties. Automakers must balance these mandates with consumer demand for affordable EVs, a challenge exacerbated by charging infrastructure gaps [17].

Conclusion

The automotive industry's ability to navigate geopolitical and climate risks will define its valuation landscape in the coming years. While supply chain resilience strategies like diversification, localization, and technology investments are mitigating some pressures, operational risk exposure remains high. Investors must prioritize automakers that integrate resilience into their core strategies, as these firms are better positioned to withstand volatility and capitalize on emerging opportunities in the EV transition.

Comentarios

Aún no hay comentarios