AI-Driven Industrial Efficiency in Shipbuilding: Hyundai's Strategic Capital Allocation and Its Global Impact

AI as a Catalyst for Operational Efficiency

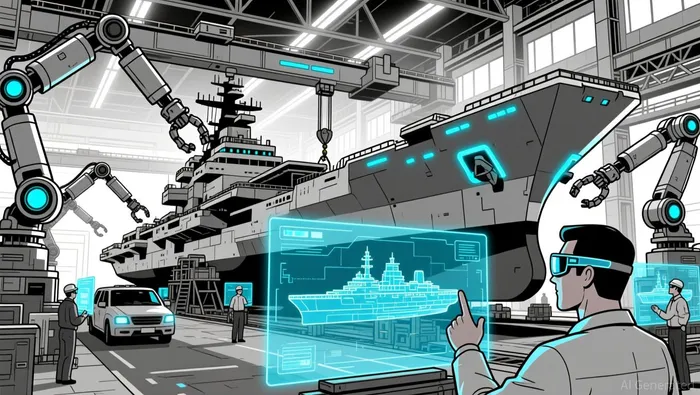

Hyundai's Future of Shipyard (FOS) project, launched in 2021, exemplifies the company's commitment to AI-driven automation. By 2030, the initiative aims to reduce shipbuilding time by 30% through robotics, AI, and digital twins. This is not mere speculation: in Q3 2025, Huntington Ingalls Industries (HII) reported a 16.1% revenue increase to $3.2 billion, driven by a 18% rise in shipbuilding sales. Such gains are underpinned by partnerships like the one with Siemens, which automates block assembly and optimizes production via data-driven solutions.

Hyundai's in-house AI platforms-Oceanwise, HD Agent, and Myeong-Jang Agent-further illustrate its focus on data-driven decision-making. These tools, showcased at APEC 2025, are designed to enhance design accuracy, reduce production risks, and cut costs. For instance, the collaboration with C3 AI in 2025 accelerates shipbuilding throughput by applying AI to supply chain logistics. Such innovations are not just incremental; they represent a systemic reengineering of an industry historically resistant to change.

Hyundai's in-house AI platforms-Oceanwise, HD Agent, and Myeong-Jang Agent-further illustrate its focus on data-driven decision-making. These tools, showcased at APEC 2025, are designed to enhance design accuracy, reduce production risks, and cut costs. For instance, the collaboration with C3 AI in 2025 accelerates shipbuilding throughput by applying AI to supply chain logistics. Such innovations are not just incremental; they represent a systemic reengineering of an industry historically resistant to change.

Strategic Capital Allocation: A $350 Billion Bet on the Future

Hyundai's capital allocation strategy is as bold as its technological ambitions. The "Make American Shipbuilding Great Again (MASGA)" initiative, a multibillion-dollar partnership with Cerberus Capital and the Korea Development Bank (KDB), targets three pillars: U.S. shipyard modernization, supply chain reinforcement, and advanced technology development. This aligns with a broader $350 billion investment package between South Korea and the U.S., with $150 billion earmarked for shipbuilding cooperation.

The scale of investment is staggering. By 2030, Hyundai Motor Group plans to allocate KRW 77.3 trillion, including KRW 30.9 trillion ($22 billion) for R&D and KRW 38.3 trillion ($27 billion) for CAPEX. Domestically, a 50.5 trillion won ($346 billion) five-year plan focuses on AI, robotics, and hydrogen. Globally, the company has committed $21 billion to U.S. growth from 2025–2028, with $6 billion dedicated to AI and autonomous driving. These figures underscore a calculated, long-term vision to dominate next-generation industrial ecosystems.

Reshaping U.S. Defense Procurement and Supply Chains

Hyundai's influence extends beyond commercial shipbuilding into U.S. defense procurement. A 2025 memorandum of agreement (MOA) between Hyundai Heavy Industries (HHI) and Huntington Ingalls IndustriesHII-- (HII) targets joint bids for Navy programs like the next-generation logistics ship (NGLS) contract. By combining HII's naval expertise with HHI's AI and automation capabilities, the partnership aims to address U.S. shipbuilding capacity constraints while aligning with national security priorities.

This collaboration is critical given the U.S. Navy's urgent need to expand its fleet. Hyundai's $5 billion investment with Cerberus to modernize U.S. shipyards and adopt autonomous navigation technologies directly addresses bottlenecks like outdated infrastructure and labor shortages. While challenges persist-such as restrictive immigration policies limiting skilled labor access-Hyundai's capital-intensive approach mitigates these risks through automation and strategic acquisitions.

Global Supply Chain Implications

Hyundai's AI-driven shipbuilding is also reconfiguring global supply chains. By digitizing design and production processes, the company reduces reliance on fragmented, geographically dispersed suppliers. For example, the Siemens partnership optimizes production workflows, minimizing delays and inventory costs. Similarly, AI-powered platforms like VesselWise and AI-CHS, showcased at Gastech 2025, streamline energy solutions for maritime operations.

These advancements position Hyundai as a linchpin in a more integrated, data-centric supply chain. As U.S.-Korea trade agreements evolve-such as South Korea's recent tariff deal with the U.S.-Hyundai's AI-driven efficiency becomes a competitive advantage, enabling faster, cheaper production while adhering to stringent defense and commercial standards.

Conclusion: A New Era of Industrial Capitalism

Hyundai's AI-driven shipbuilding strategy is a masterclass in strategic capital allocation. By pairing massive investments in R&D and automation with cross-border partnerships, the company is not only boosting operational efficiency but also reshaping global supply chains and U.S. defense procurement. For investors, this represents a rare convergence of technological innovation, geopolitical alignment, and financial scalability. As the industry shifts from analog to digital, Hyundai's playbook offers a roadmap for industrial dominance in the 21st century.

Comentarios

Aún no hay comentarios